26

Troubleshooting – Operational Problems

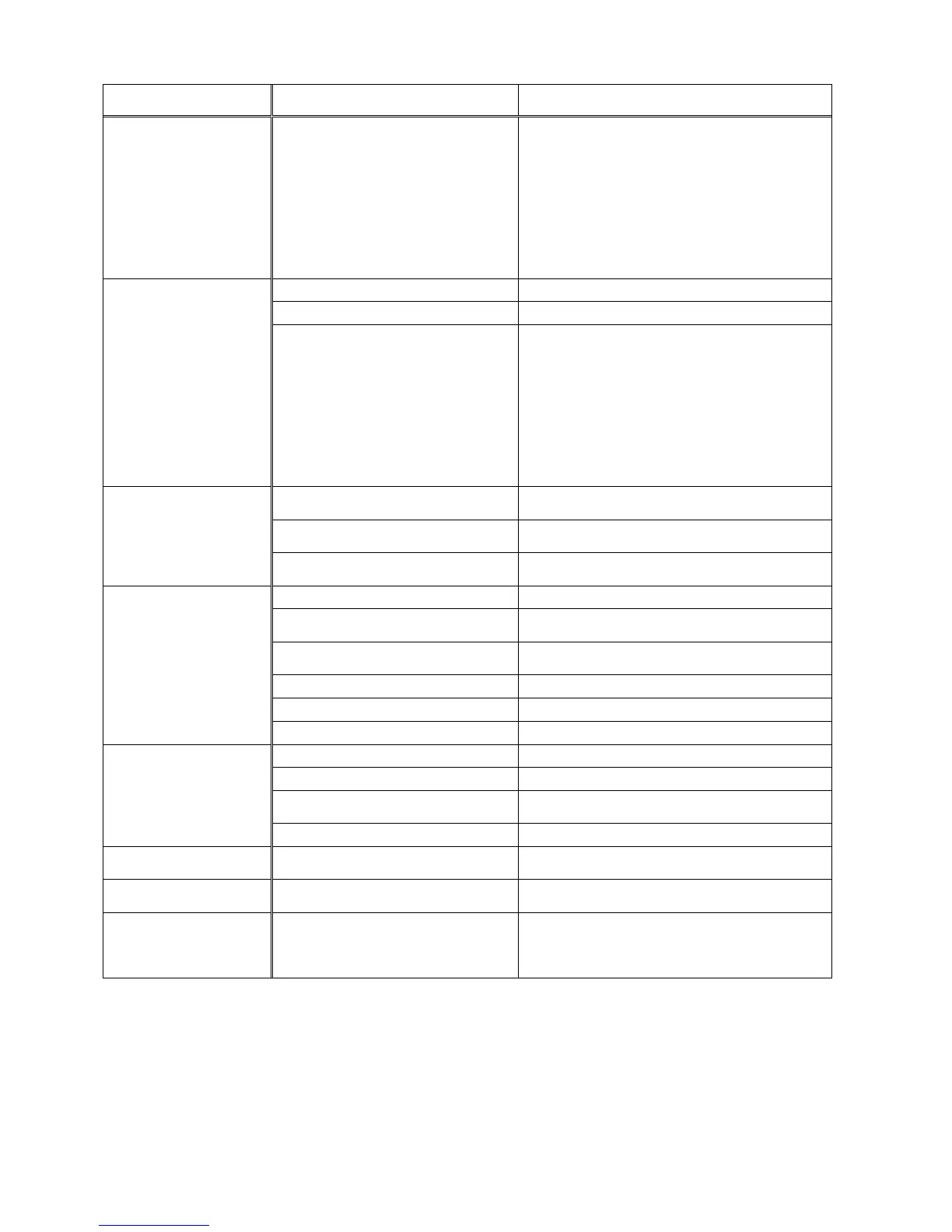

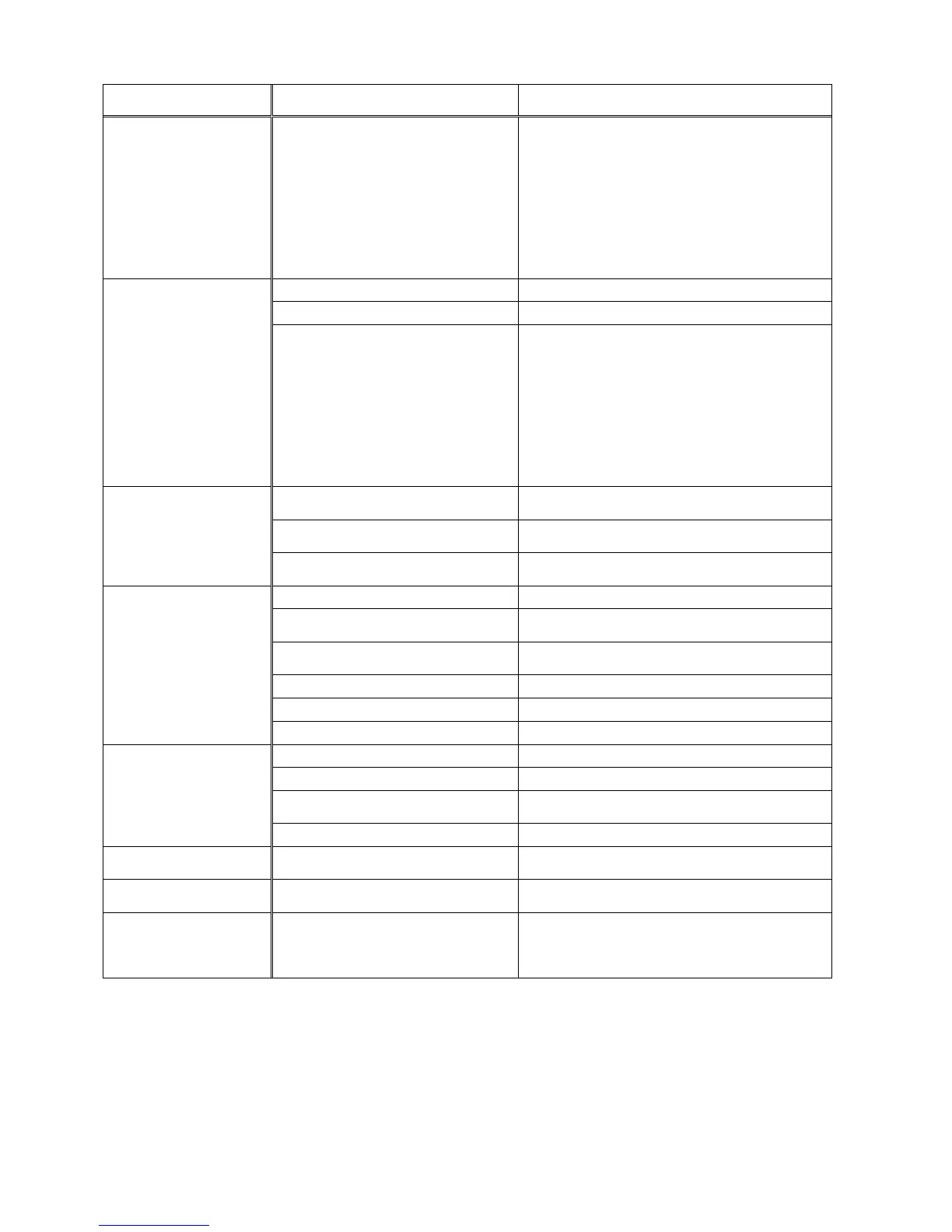

Trouble Probable Cause Remedy

Ripples in sanded

surface.

(Non-uniformly spaced

ripples).

Uneven feed rate. Check for these conditions and refer to

previous Troubleshooting sections:

- Conveyor belt slips on drive roller.

- Board slips on conveyor belt.

- Conveyor gear motor stalls.

- Excessive v-belt tension.

- Set-screw loose on shaft coupler

between gear motor and conveyor.

- Conveyor bushings worn – replace.

- Conveyor bushings dry – lubricate.

Ripples in sanded

surface.

(Uniformly spaced

ripples).

Excessive feed rate. Reduce depth of cut and/or feed rate.

Excessive depth of cut. Reduce depth of cut and/or feed rate.

Sander vibration.

Check for these conditions:

- Loose bolts, or loose bearing and pulley

set-screws – re-tighten.

- Dirty drum – clean inside.

- Excessive v-belt tension – reduce

tension.

- Worn v-belt – replace.

- Warped drive pulley – replace.

- Drum out of balance – contact your dealer or

JET authorized service center.

Sniping of wood

(gouging near end of

board).

Tension rollers set too low.

Re-set tension rollers; see Tension Roller

Adjustment.

Stock not supported properly during

infeed or outfeed.

Support stock with roller stand, tables or

benches.

Conveyor drive roller or driven roller

higher than conveyor belt surface.

Re-adjust roller(s).

Burning of wood.

Feed rate too slow. Increase feed rate.

Excessive depth of cut for grit used.

Reduce depth of cut or increase grit

coarseness.

Excess build-up on abrasive strips.

Reduce depth of cut; clean strips or replace;

angle stock when feeding.

Abrasive is too fine. Replace with abrasive of coarser grit.

Abrasive strips are overlapped. Rewrap strip without overlap. See pages 11-12.

Drum out of alignment. Re-align drum. See pages 16-17.

Gouging of wood.

Conveyor belt is loose. Adjust conveyor belt tension. See page 15.

Excessive depth of cut. Reduce depth of cut.

Wood slipping on conveyor due to

lack of contact.

Use alternate feeding procedure.

Abrasive is too fine. Replace with coarser grit.

Line or groove in stock. Inconsistent feed rate.

Do not stop or change the feed rate while

feeding stock.

Lines or groove in stock

while in oscillation mode

Feed rate not set to maximum. Set feed rate to maximum.

Unsanded ridge along

length of piece

(sandpaper appears

clean).

Grit has been removed from

backing.

Avoid this area of drum, or replace abrasive

strip.

Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call

1-800-274-6848, Monday through Friday (see our website for business hours, www.jettools.com). Having

the Model Number and Serial Number of your machine available when you call will allow us to serve you

quickly and accurately.

Loading...

Loading...