83

TwinForce™ Series Waterblast Unit

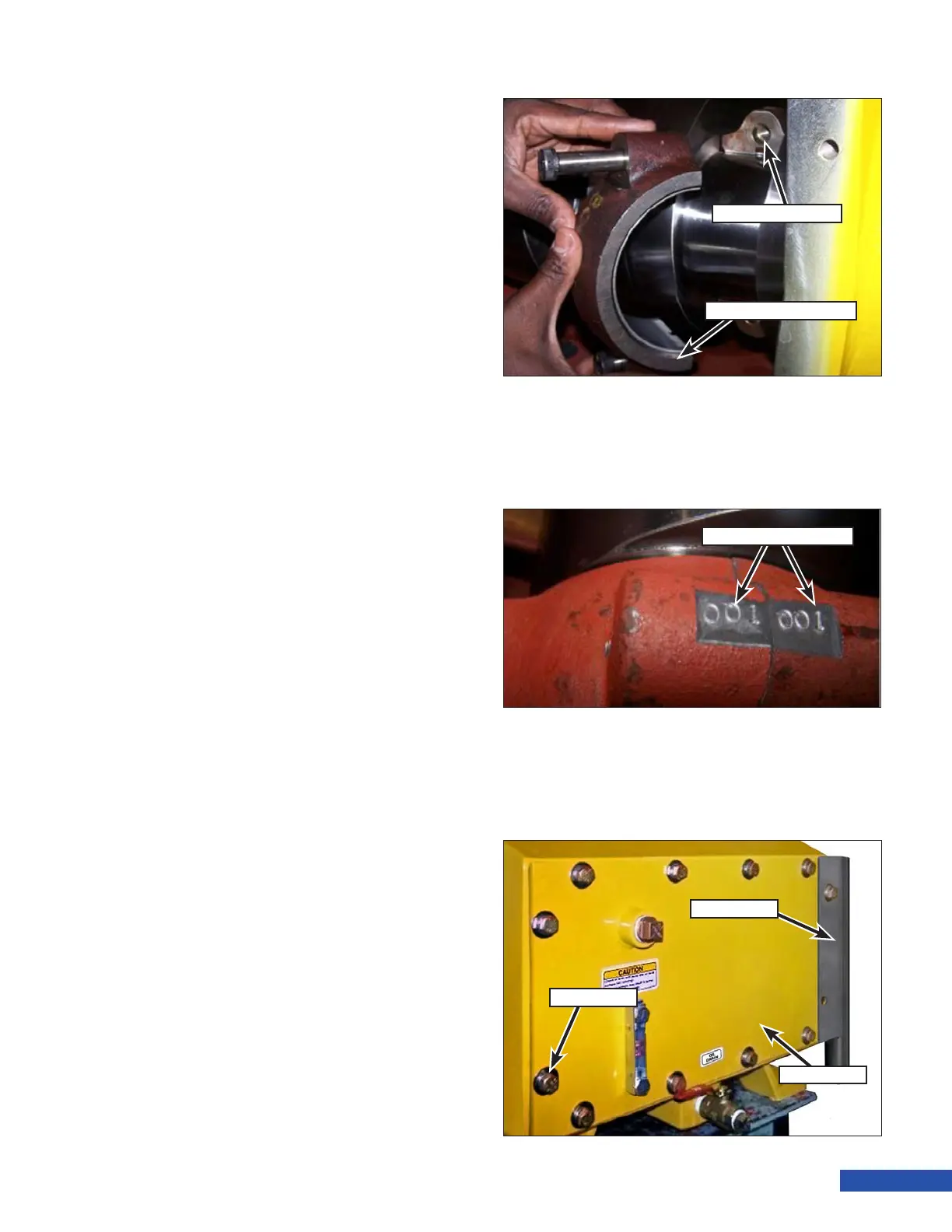

6. Pull the connecting rod (Figure 164) onto

the crankshaft and place the rod cap into

position aligned with the connecting rod.

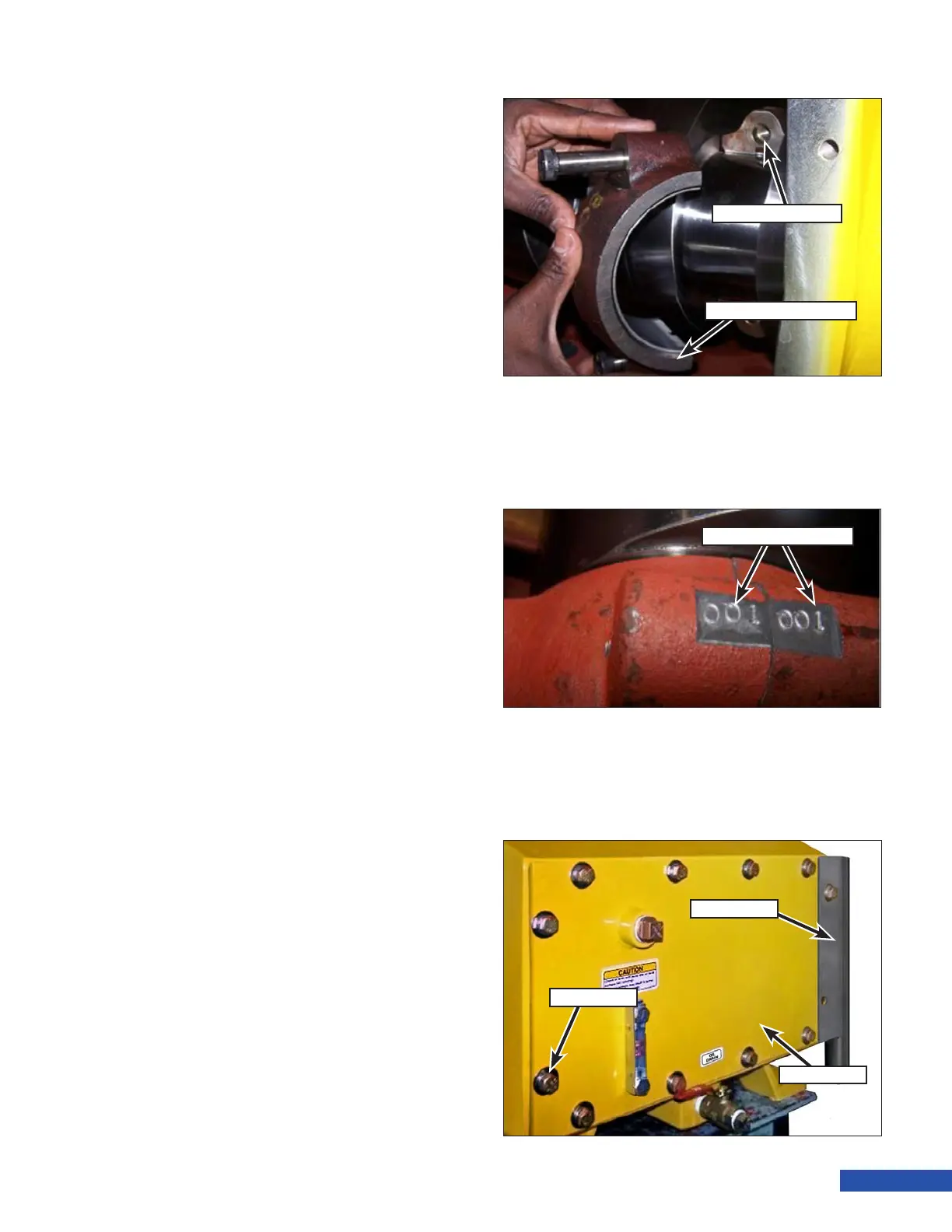

Ensure the stampings (Figure 165) on the

cap and rod match.

7. Screw in the capscrews by hand and then

tighten to the proper torque:

• 3000 Series Pumps: 45 ft.lb (61 N·m)

• 3600/4200 Series Pumps: 80 ft.lb (108

N·m)

8. With the rst rod connected, rotate the

pump by pulling the belts. Allow the

crankshaft to turn a few revolutions to

ensure the rod was properly installed.

If the crankshaft spins freely, the bearings

were properly installed.

If the crankshaft does not spin freely, re-

move the journal bearings and replace with

another set.

9. Repeat the previous steps for installation

of the remaining journal bearings.

10. Place the back plate (Figure 166), belt

guard and gasket into position on the

frame.

11. Install the capscrews, lock washers and

at washers. Tighten the capscrews to the

proper torque.

• 3000 Series Pumps: 20 ft.lb (27 N·m)

• 3600/4200 Series Pumps: 35 ft.lb (47

N·m)

12. Fill the power end with oil as outlined in

“Changing the Power End Oil” on page

73.

Figure 164: Rod Cap Installation.

Rod Cap & Bearing

Connecting Rod

Figure 165: Matched Parts Stampings.

Rod Cap & Bearing

Belt Guard

Back Plate

Cap SCrew

Figure 166: Cover Plate Installation.

Loading...

Loading...