85

TwinForce™ Series Waterblast Unit

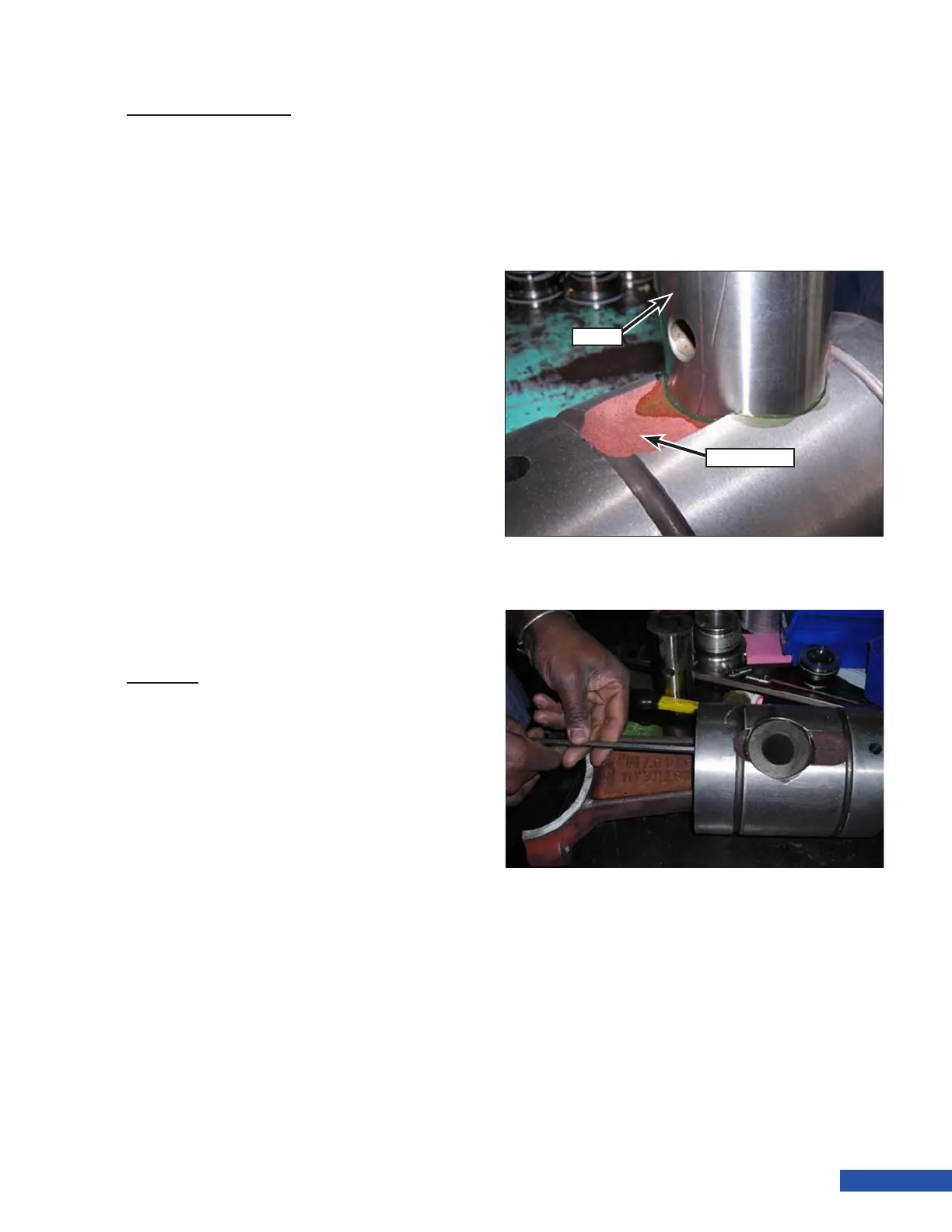

Figure 169: Pin Placement.

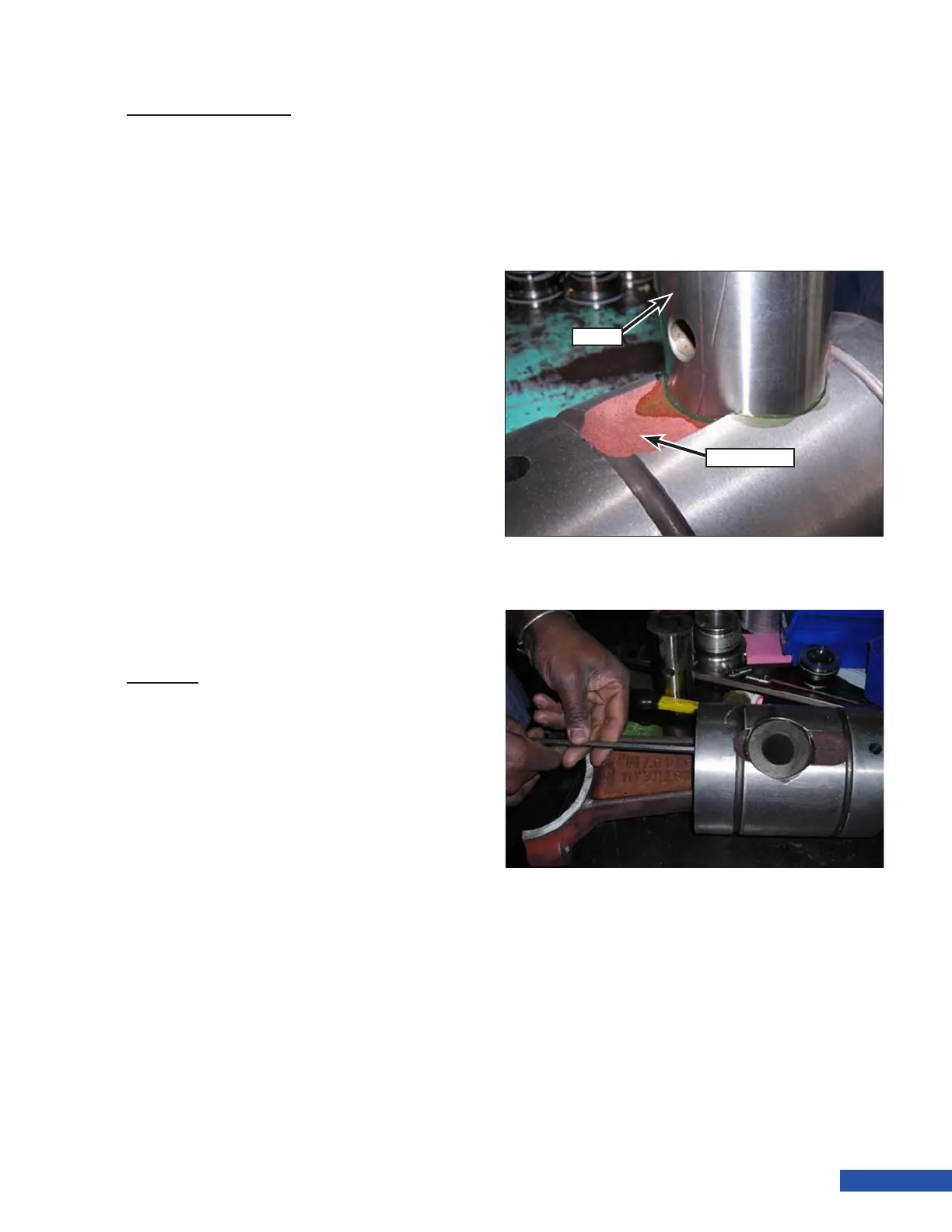

Figure 170: Second Set Screw Installation.

Pin

Crosshead

Crosshead Inspection

1. Use a micrometer to measure the outer

diameter of the crosshead in three places

and record the measurements.

2. Add the three measurements and divide

by 3 to get the average diameter.

3. Use an inside micrometer to measure

the crosshead bore in the power frame

in three places and record the measure-

ments.

4. Add the three measurements and divide

by 3 to get the average diameter.

5. Subtract the diameter of the crosshead

from the inside diameter of the cross-

head bore. If the remainder is greater than

0.012 in. (0.31 mm), the crosshead must

be replaced.

Note: New part clearances are as fol-

lows:

• Series 3000: 0.004 in. (0.1 mm) - 0.007

in.(0.2 mm)

• Series 3600/4200: 0.006 in. (0.15 mm) -

0.009 in. (0.23 mm)

6. Repeat for the remaining assemblies.

Assembly

1. Clean all surfaces of the crossheads, pins,

and connecting rods using brake cleaner.

2. Inspect all surfaces of the crossheads,

pins, and connecting rods for any signs of

damage. Replace any suspect or damaged

parts.

3. Inspect the long bore oil passage through

the length of the connecting rod. Use a wire

or a long handle brush to clear passage if

necessary.

4. Insert the connecting rod into the bottom

of the crosshead and line up the bores.

5. Lubricate the pin (Figure 169) with clean

oil and insert the pin into the hole in the

side of the crosshead.

6. Align the hole in the connecting rod with

the pin as it is slipped in.

7. Thread the rst set screw into the cross-

head hole until it touches the pin, then

back off a 1/4 turn. Slide the pin into posi-

tion and tighten the set screw ensuring

the screw is engaged in the counterbore

of the pin. Tighten the set screw to 30 ft lb

(41 N·m).

8. Apply Loctite Red-271© onto the threads

of the second backup set screw.

9. Install the second set screw on top of the

rst set screw. Tighten to 36 ft lb (49 N·m)

(Figure 170).

10. The crosshead is now ready for installa-

tion in the pump.

Loading...

Loading...