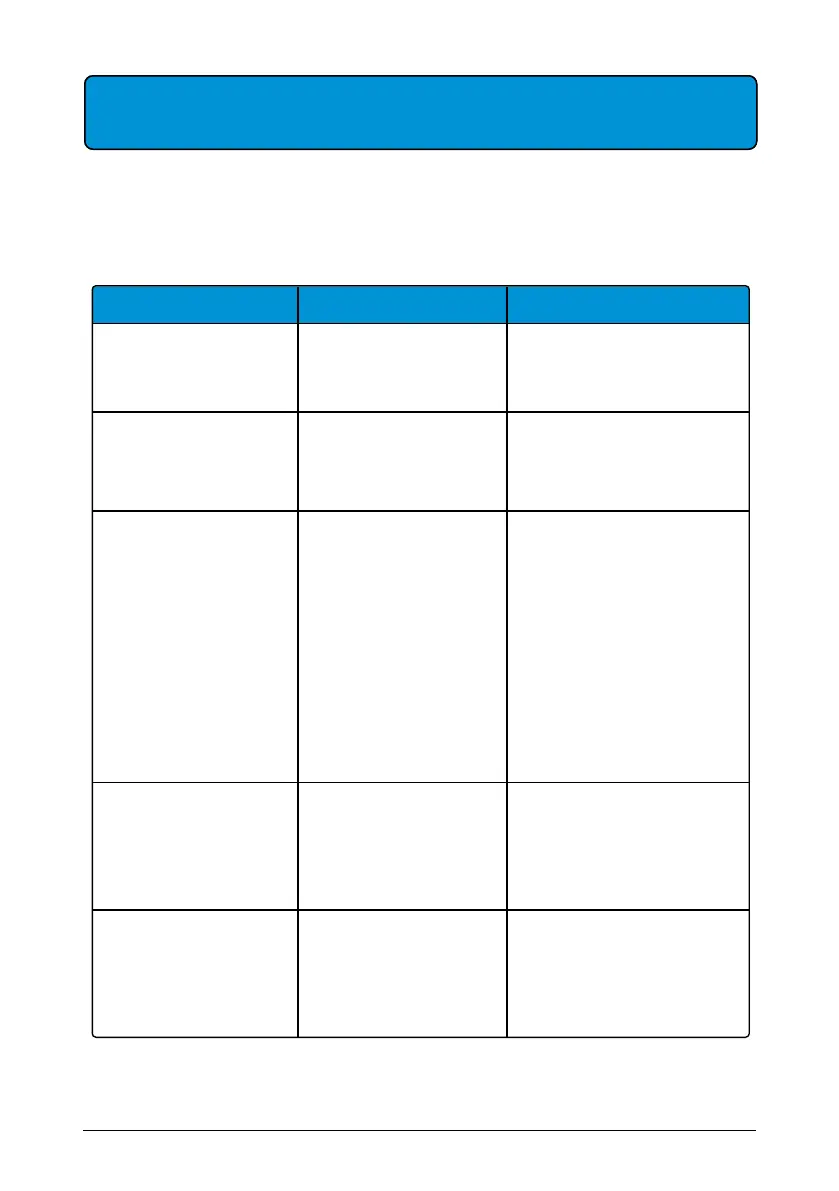

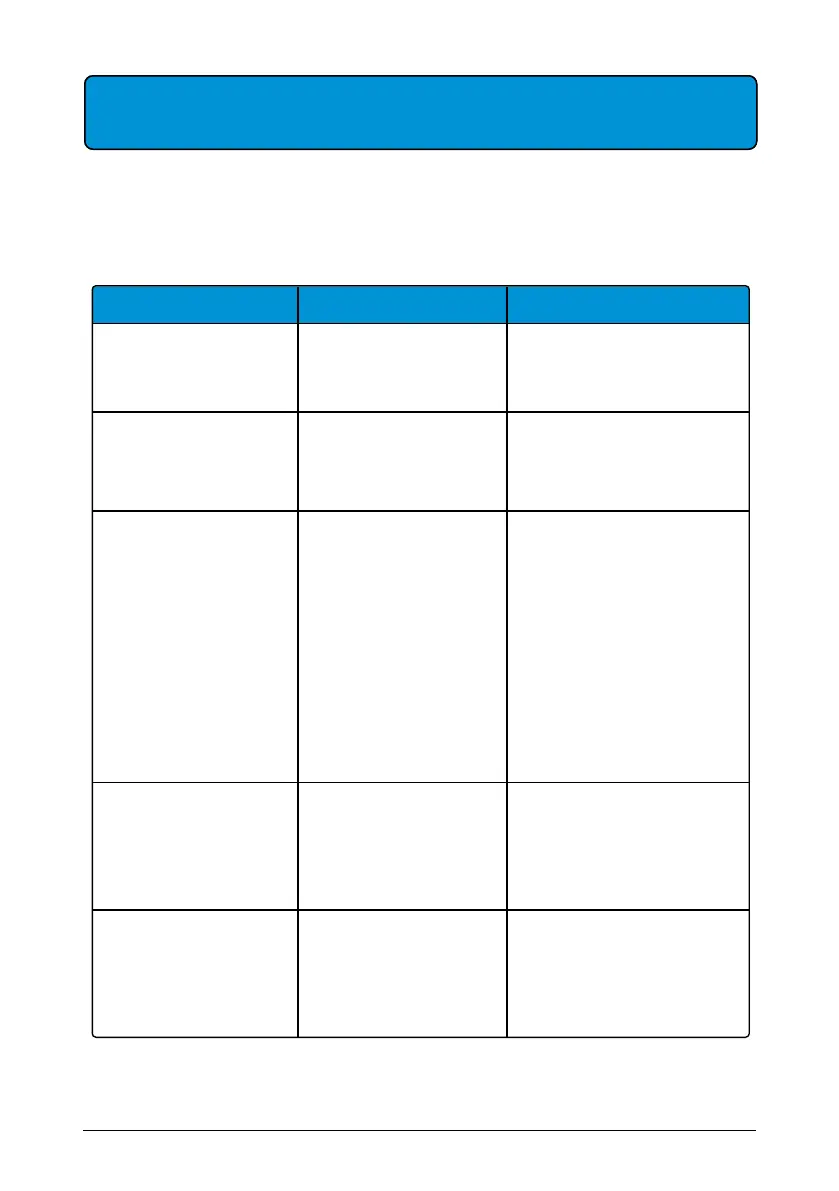

Problem Cause Action

l Noise from pump.

1. Pump draws air.

2. Insufficient oilvolume.

3. The pump is defective.

1. Checkconnections.

2. Adjust the amount of oil.

3. Replace pump.

l Nothing works.

1. Emergencystop has

been activated.

2. Fuse/relay has tripped.

1. Switch off the engine, pullout

the emergencystop button

and restart.

2. Replace fuse/relay.

l Noise from cylinders.

l Jerky hydraulic move-

ment.

l Oil sprays from the

tank.

1. The piston rod is dam-

aged.

2. Air in the hydraulic sys-

tem.

3. Valve or piston fault in

pump.

4. Oil level in the tank too

high or too low.

5. Pump draws air.

6. The tank’s air filter is

blocked.

1. Replace the piston rod.

2. Checkthat the suction line is

sealed.

3. Service or replace the pump.

4. Adjust the oillevel.

5. Service or replace the pump.

6. Replace filter.

l Poor lifting capacity.

1. Insufficient amount of oil

to the pump.

2. Oil pressure too low.

3. Leaking cylinder gas-

kets.

1. Checkthe oil level.

2. Contact JOAB.

3. Replace the cylinder gaskets.

l Controller or levers

jam

1. Chain lock/lever jams.

2. Spring set for air cylinder

broken.

3. Solenoid jams.

1. Remove, lubricate and rein-

stall.

2. Replace spring set.

3. Clean solenoid. Replace it, if

necessary.

Loading...

Loading...