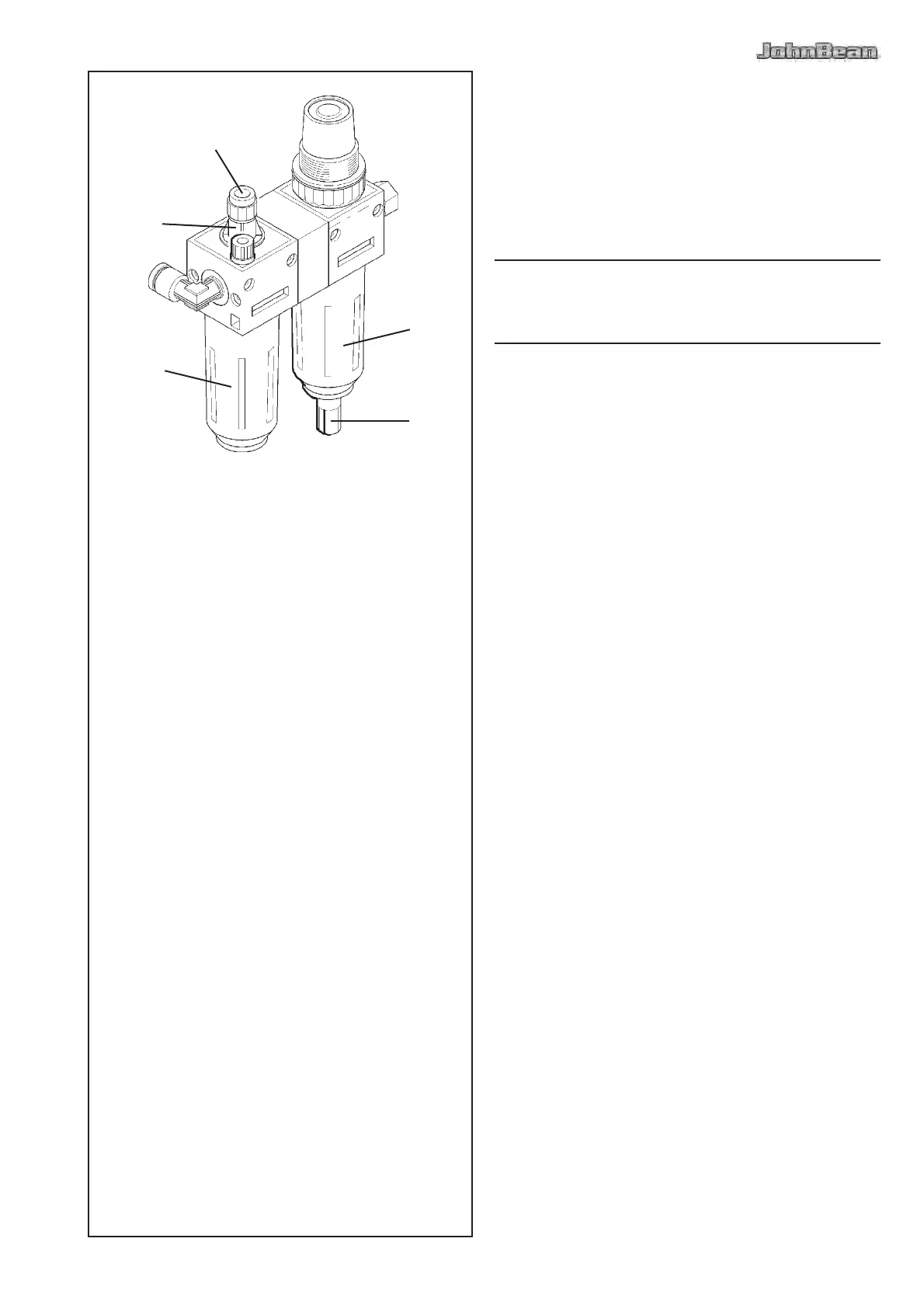

6.0-3

R

G

T

S

F

EN - 29

H. Check and discharge the water every day from air ! lter/

water separator ‘F’. Do this by pulling down the ! tting “S”

(Fig. 6.0-3).

I. The machine is equipped with an automatic lubricator.

Check the oil level weekly. When adding oil to the

lubricator, disconnect the air supply ! rst, and add oil as

needed. Make sure seals are in place when repositioning

the cup.

WARNING"

PAY ATTENTION TO KEEP FILLED THE OIL TANK OF

THE OILER, EXPECIALLY FOR AIR MOTOR OPERATED

MACHINES.

USE ONLY OILS FOR AIR DEVICES, DO NOT USE

BRAKE FLUID OR OTHER NON RECOMMEND

LUBRICANTS.

Suggested oils for the ! lter/lubricator unit:

WHITE MINERAL OIL: 15 cSt

TAMOIL: WHITE MINERAL OIL 15

SHELL: ONDINA OIL 15

BP: ENERGOL WT3

TOTAL: LOBELIA SB 15

ESSO: MARCOL 82

J. Periodically check the lubricator ef! ciency. One oil drop

(G, Fig. 6.0-3) every 4-5 operations of the bead breaker

indicates that the correct amount of oil is being dispersed

in the system.

If necessary adjust the oil # ow with screw (R, Fig. 6.0-3).

K. If the machine is also equipped with a beading unit

for tubeless tires, drain condensation from the tank daily.

6.1 Storage

In case the machine is not to be used for a long period of

time (6

months or more) it is necessary to disconnect all

power sources, discharge the bead seater tank (only GP

version), protect all parts that may be damaged, protect

the air hoses that may be damaged by the drying process.

When putting the machine back in operation, check ! rst

the condition of all previously protected parts, and check

for correct functioning of all devices before using the

machine again.

Loading...

Loading...