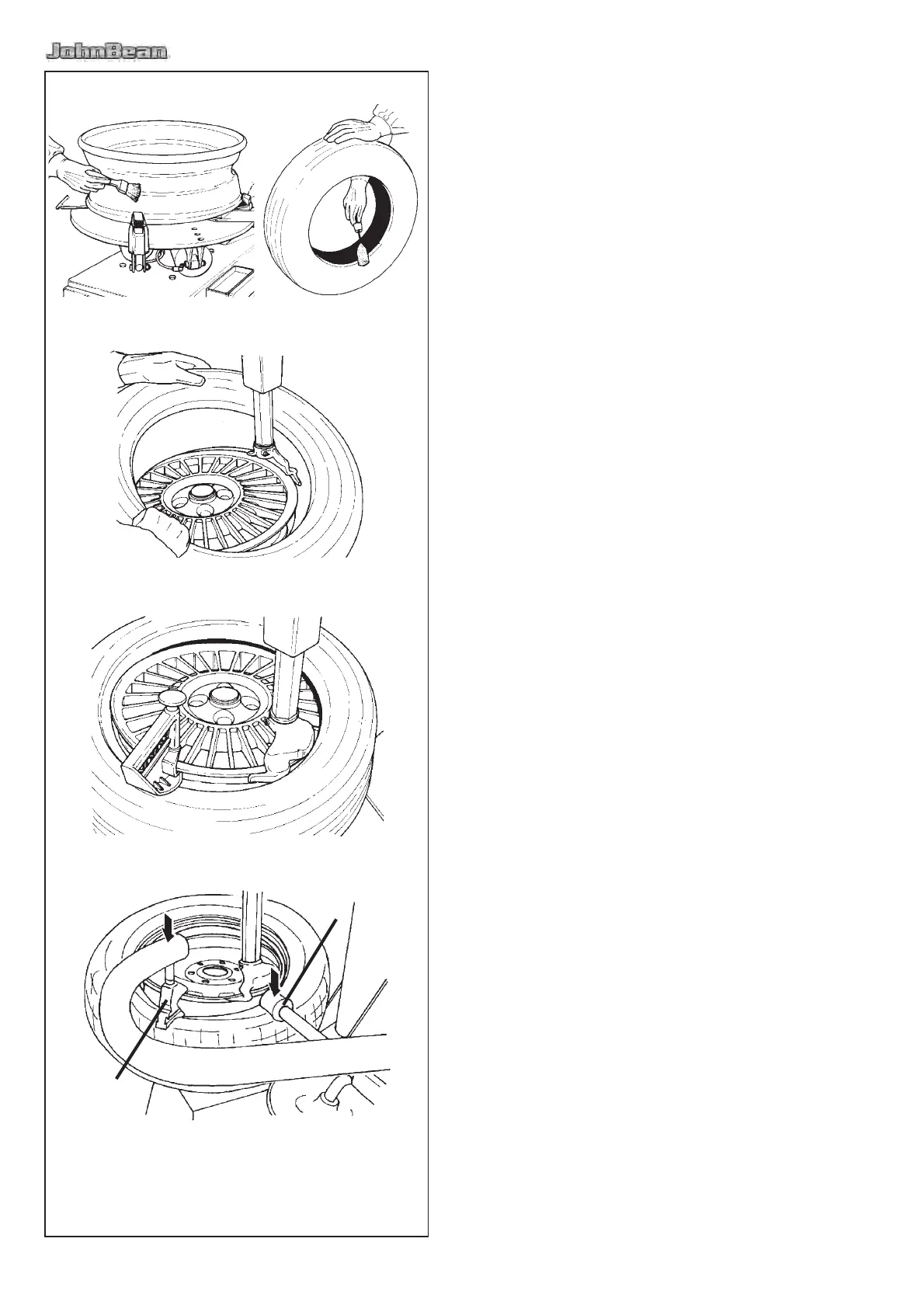

5.2-1

5.2-2

5.2-3

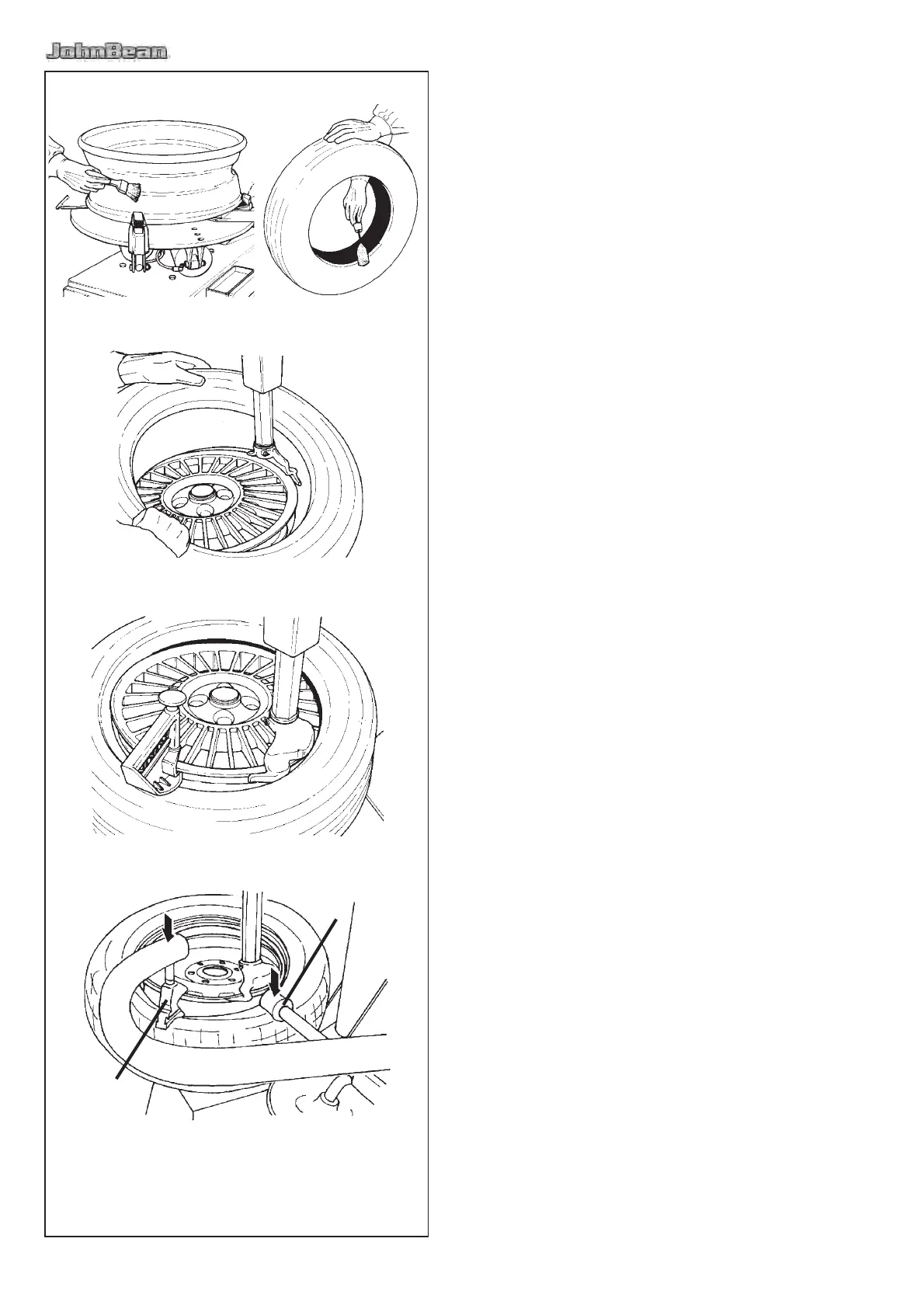

5.2-4

1

2

22 - EN

5.2 Mounting tubeless tyres

• Lubricate the entire rim surface. Lubricate both beads,

inside and outside, (Fig. 5.2-1).

OBSERVE THE ROTATION DIRECTION OF

THE TIRE, IF REQUIRED. SOME TIRES HAVE

A COLOR DOT THAT MUST BE KEPT ON THE

OUTSIDE OF THE WHEEL.

LIBERAL LUBRICATION OF THE TIRE AND RIM

IS NECESSARY TO MOUNT TIRE CENTERING

CORRECTLY AND GET A PROPER ON THE

RIM. BE SURE YOU ARE USING APPROVED

LUBRICANT ONLY.

• Lock the rim on the turntable and rotate it to have the

valve in 5 o’clock position. Place the tire to be mounted

on the rim. Swing the mounting arm forward so that the

mount/demount tool is in the working position. Engage

the lower bead OVER the mounting wing and UNDER

the mounting ! nger of the mounting tool. Turn the wheel

clockwise and push the tire down into the drop center,

opposite to the mount/demount head (Fig. 5.2-2).

• Mount the upper bead following the directions in

section B (Fig. 5.2-3). With low pro! le tyres the bead

depressor tool “MX” (optional #EAA0247G70A) can

help to facilitate mounting of the top bead.

NOTE: FOR NARROW SIDEWALLS, RUN FLATS, OR

EXPECIALLY STIFF TIRES IT IS RECOMMENDED TO

USE THE MH 310 PRO ACCESSORY (Fig. 5.2-4).

A. Mount the first bead. After having positioned the

mounting/demounting tool, position the roller (ref. 1) and

the tool (ref. 2) as shown in Fig. 5.2-4.

B. Lower the bead pusher so that the roller and the bead

pusher tool on the tire help keeping the bead into the drop

center (Fig. 5.2-4).

Before distancing the mounting/demounting tool from the

tyre changer machine, set the roller and the tool pusher

in the rest position.

Loading...

Loading...