iii-1

EN - 37

Pneumatic installation

THE AIR INSTALLATION MUST BE PERFORMED ONLY

BY LICENSED PERSONNEL.

The machine requires an air pressure of 8 to 12 bar (110-

170 psi), as marked on the plate of the machine and on a

sticker attached to the cabinet next to the air inlet.

Ensure that the line pressure is within the limits required

by the machine.

If the air pressure is lower than the minimum required of 8

bar (110psi) the clamping power of the turntable and the

bead breaker power may be insuf! cient for certain tIres.

If the air pressure exceeds 12 bar (170 psi) it is mandatory

to install a pressure regulator before the air inlet of the

machine.

It is suggested that the air supply be equipped with a water

separator to reduce the amount of water at the air inlet.

Connect the machine to the air supply with a rubber

hose (rated for the pressure) with an inside diameter of

6 mm (1/4”). A ¼” NPT ! tting is provided at the air inlet.

BEFORE CONNECTING THE MACHINE TO THE AIR

SUPPLY BE SURE THAT NOTHING IS LEFT ON THE

TURNTABLE AREA (TOOLS,ETC).

After ensuring all the above proceed as follows:

• Connect the machine to the air supply (max. pressure

of 12 bar - 170 psi) with a rubber hose (rated for the

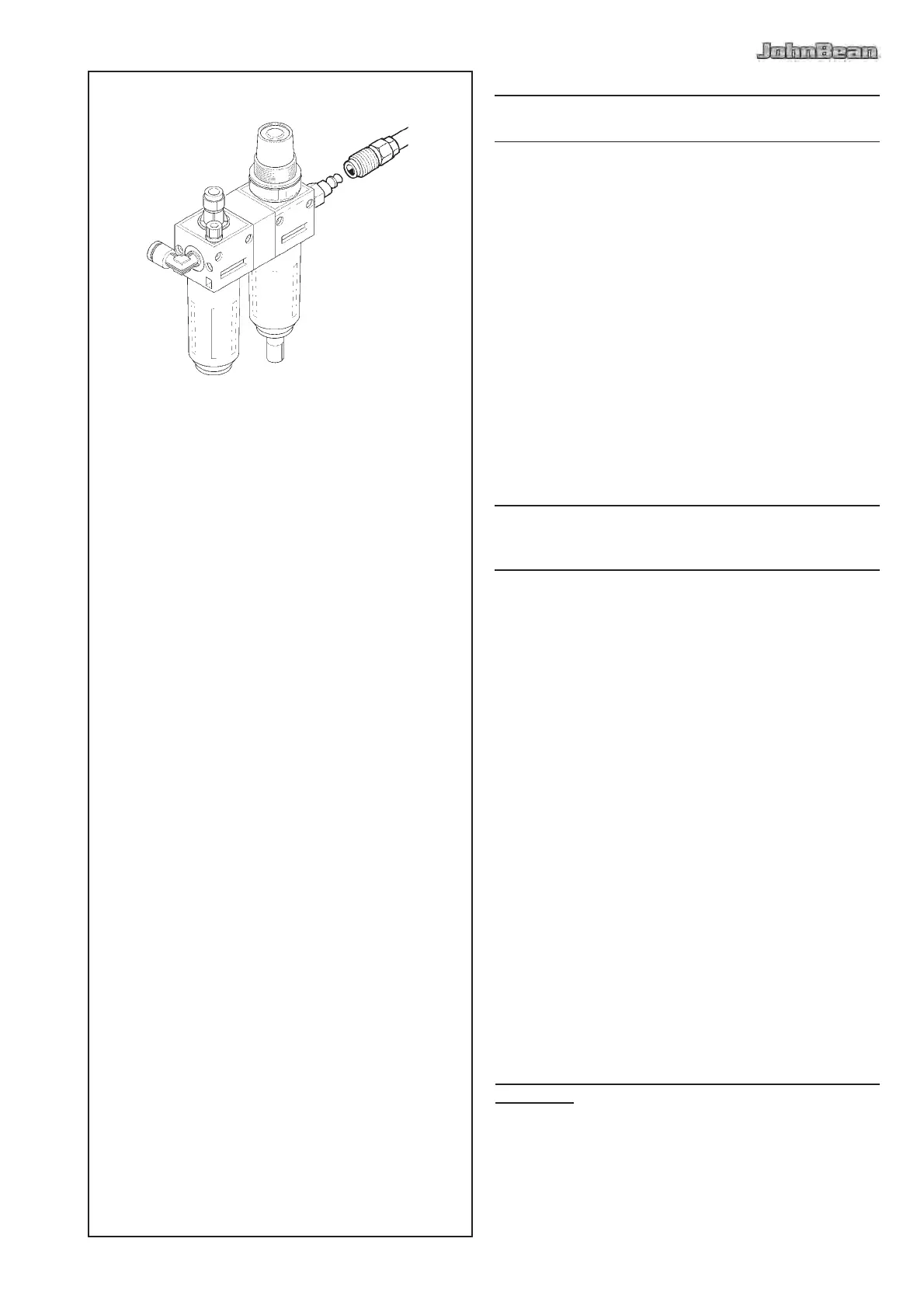

pressure) with an inside diameter of 6 mm (1/4”) (Fig.

iii-1).

• To install any accessory on request follow the

instructions enclosed with it.

• In case of installation of an air-! lter and lubricator,

check correct functioning.

Pneumatic hose connection check

When ! rst setting the machine into operation, check

hose connections and unions for leakage.

iv Instructing the operator

(Following applies only if a unit is installed by a service

Technician)

• Show the operator how to switch the unit on and off.

Loading...

Loading...