210.100-IOM (JUL 2021)

Page 47

AcuAir Hygienic Air Units

Maintenance

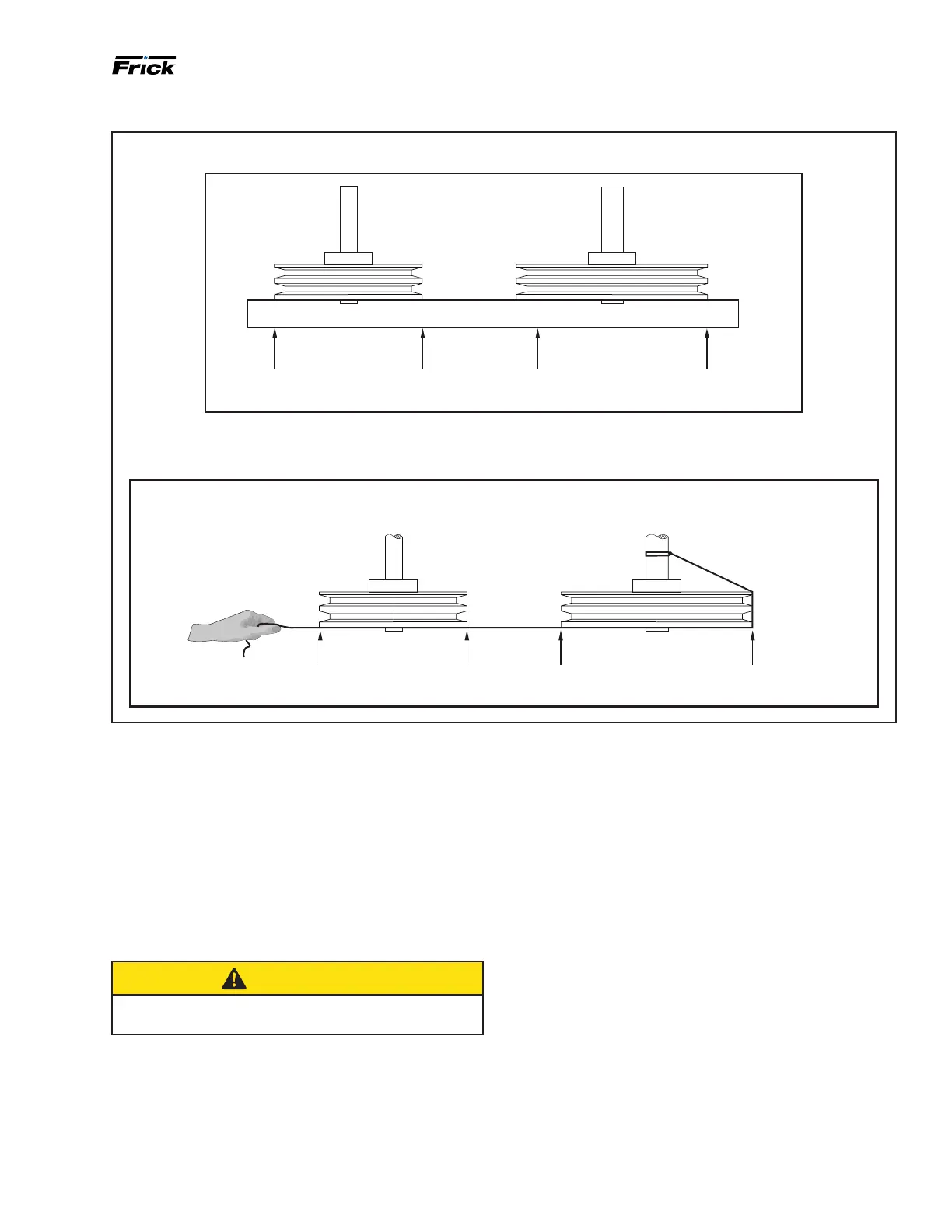

Straightedge touching sheaves at points indicated by arrows.

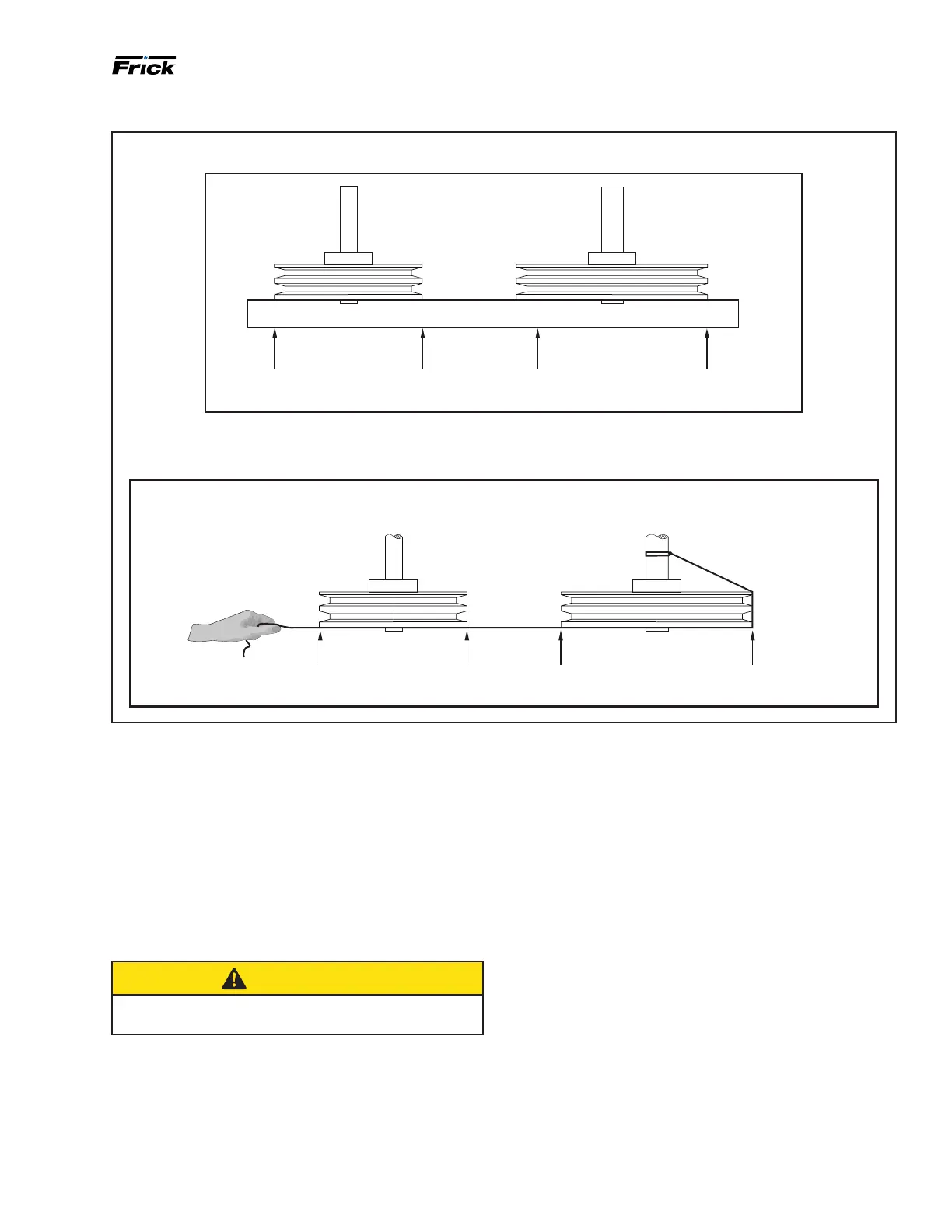

Cord touching sheaves at points indicated by arrows.

ALIGNMENT USING STRAIGHTEDGE (A)

ALIGNMENT USING STRING (B)

Cord tied

to shaft

Replacing belts

Always replace belts as a matched set. Used belts are

always longer because of stretching and never install new

belts singly on a matched drive. Follow the steps below to

replace belts:

1. Release the tension on the belts by loosening the ad-

justing nuts on the fan motor.

2. Remove old belts and verify the sheave alignment with

a straight edge.

3. Install the new belts on the sheave.

CAUTION

Never place the belts on the sheaves by using a

screwdriver to pry the belt over the rim of the sheave.

Tensioning V-belts and sheaves

1. Correct belt tensioning data is located on V-belt Drive

Kit label, which is mounted on inside of fan access

door.

2. Adjust the belt tension using the adjusting nuts on the

motor mount.

3. The ideal tension is the lowest tension at which the

belt does not slip during start-up.

4. Inspect tension after:

• The rst 24 hr of operation.

• One week of operation.

New belt tension drops rapidly during the rst few

hours of operation.

5. Overtensioning shortens belt and bearing life.

6. Keep belts free from foreign material, which may cause

slip.

7. Make V-drive inspection on a periodic basis. Tension

belt when slipping is observed. Never apply belt dress-

ing, because this damages the belt and cause early

failure.

Figure 54: Sheave alignment

Loading...

Loading...