210.100-IOM (JUL 2021)

Page 14

AcuAir Hygienic Air Units

Installation

Section reconnect ship loose items

• Acu-Shield roof coating

• Joint sealing caulk

• Seal gasket tape

• 1/4 in. bolts and nuts

• Electrical conduit sealing putty

Installation tools

To complete the installation of an AcuAir

®

system, the fol-

lowing tools are required:

• Drift pins

• 8 ft straight edge

• Level

• Assorted open-end wrenches

• Socket set

• Caulk gun

• Tape measure

• Chain falls

• Screw gun with nut drivers

• Paint brush or roller for applying Acu-Shield roof

coating

Assembling roof curb (optional)

1. When supplied by Johnson Controls - AcuAir

®

, roof

curbs ship either fully welded or in pieces. If bolted

curb construction, bolt together.

2. Curb must be level (shim if required). Place shims, at

fractions of an inch, at intervals no greater than 5 ft

apart. Shims are not intended to compensate for roof

pitch. Individual stacks of shims must not exceed 1/2 in.

in height. On large units with splits, remember to shim

at the split’s midspan. See Figure 8.

3. The installer is responsible to secure the roof curb to

the building structural support in accordance with local

codes.

4. Seal all roof curb joints and seams with a suitable

sealer or polyurethane caulk to prevent water leakage.

Installing roof curb

1. Verify that the curb is level and secured to the roof.

2. Verify that there is adequate height between the base

of the unit and the roof to allow for drain trapping.

3. Install a 1/8 in. thick neoprene gasket on the top of

the curb to provide a seal between the unit and the

roof curb. If the unit or unit sections must be slid into

place, a polyurethane sealant may be used in lieu of the

gasket.

4. Lift the unit in place.

5. The installer is responsible to secure installation in ac-

cordance with the local codes.

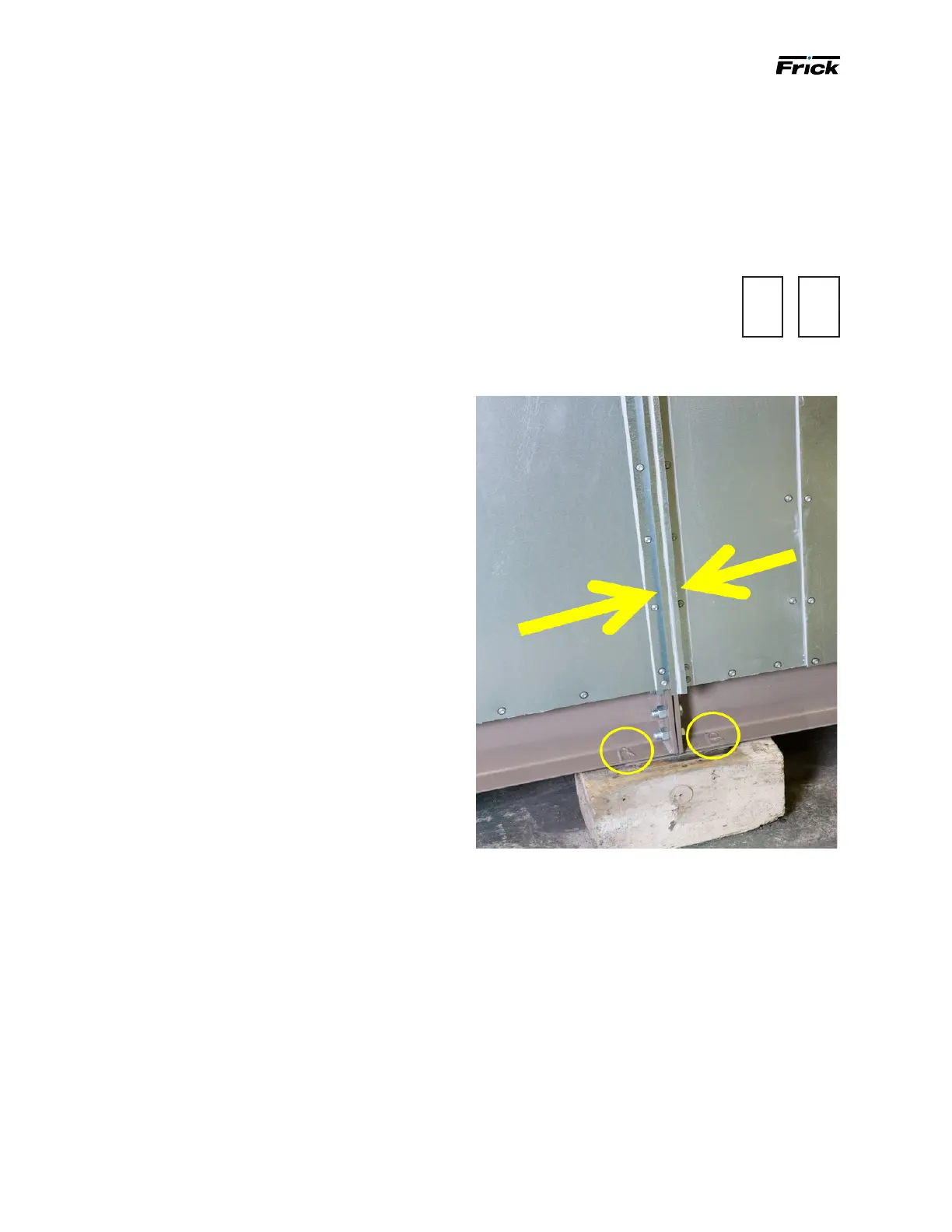

General split unit reassembly

Units that are shipped in sections, must be installed on an

appropriate foundation and carefully assembled to provide

the required unit performance.

• AcuAir

®

units must be level for reassembly.

• All bolts, nuts, washers, split covers and polyurethane

caulking (if required) can be found in supply fan sec-

tion.

• All splits are identied with welded

letters on the base channel (A-A,

B-B, for example) to indicate which

sections are to match up for reas-

sembly.

Figure 8: Food grade unit reconnection

Removable lifting lugs

You are provided with removable lifting lugs along either

the width or length of the various sections of the unit.

Lifting lugs may be repositioned before lifting. After the

sections have been placed as close as possible to each

other, remove any lifting lugs in the reconnect split. You

can use a hand-actuated winch or a come-along to bring

the unit sections together for nal bolting. Attach the hand

winch or come-along to each side of the base using the

lifting lugs relocated to the alternate side locations and

draw the sections together.

Electrical wiring and piping

It is the installer’s responsibility to reconnect all internal

and external electrical or piping splits. All wires are col-

ored or numbered to designate which wires to join at each

split. Before turning on power, check all electrical circuits

for continuity.

MATCH

A

→

MATCH

A

←

Loading...

Loading...