210.100-IOM (JUL 2021)

Page 25

AcuAir Hygienic Air Units

Installation

Attaching the AcuAir fresh air

intake plenum

The fresh air intake plenum and hoods are shipped as an

assembly on smaller cfm units. The plenums arrive with

one set of hoods unmounted for larger cfm units.

Figure 23: Fresh air intake plenum ready for shipping

Figure 24: Detached intake hoods ready for shipping

The plenums and all hoods are assembled in the factory

before preparing for shipment. Not all of the attachment

screws are installed in hoods that ship unattached.

Figure 25: Fresh air intake plenum and hoods preas-

sembled in the factory

1. For those unit arriving with unattached hoods, reattach

the hoods starting with a hood in the bottom position

rst. Use the factory attached hoods as a model and

the existing screw holes to nalize locations.

2. The AcuAir

®

unit is provided with plenum alignment

tabs and attachment clips to assist with correctly

positioning the plenum assembly and holding it in posi-

tion as it is secured to the air unit. See Figure 29. The

alignment tabs are installed in the factory.

The attachment brackets are shipped loose along with

cap screws to mount the brackets and bolts for secur-

ing the plenum in the brackets. In preparation for lifting

the plenum into position, mount the two brackets using

the cap screws provided.

3. Before placing the hood in the mounting position, apply

a continuous bead of polyurethane caulking on the face

of each vertical hood ange and across the face of the

top ange.

4. The plenum and hood assembly can be lifted using the

lifting lugs provided on the top if the plenum

5. On the blank wall of the plenum is an access panel.

This panel can be removed to provide access to the

inside of the plenum when attaching it to the fresh air

opening on the AcuAir

®

unit.

6. Apply continuous beads of polyurethane caulking on

the face of the plenum anges. Ensure the caulking is

on the outside of the factory drilled attachment screw

holes. This caulking prevents rain water from reaching

the attachment screw penetrations after the plenum is

mounted to the AcuAir

®

unit. See the following gure.

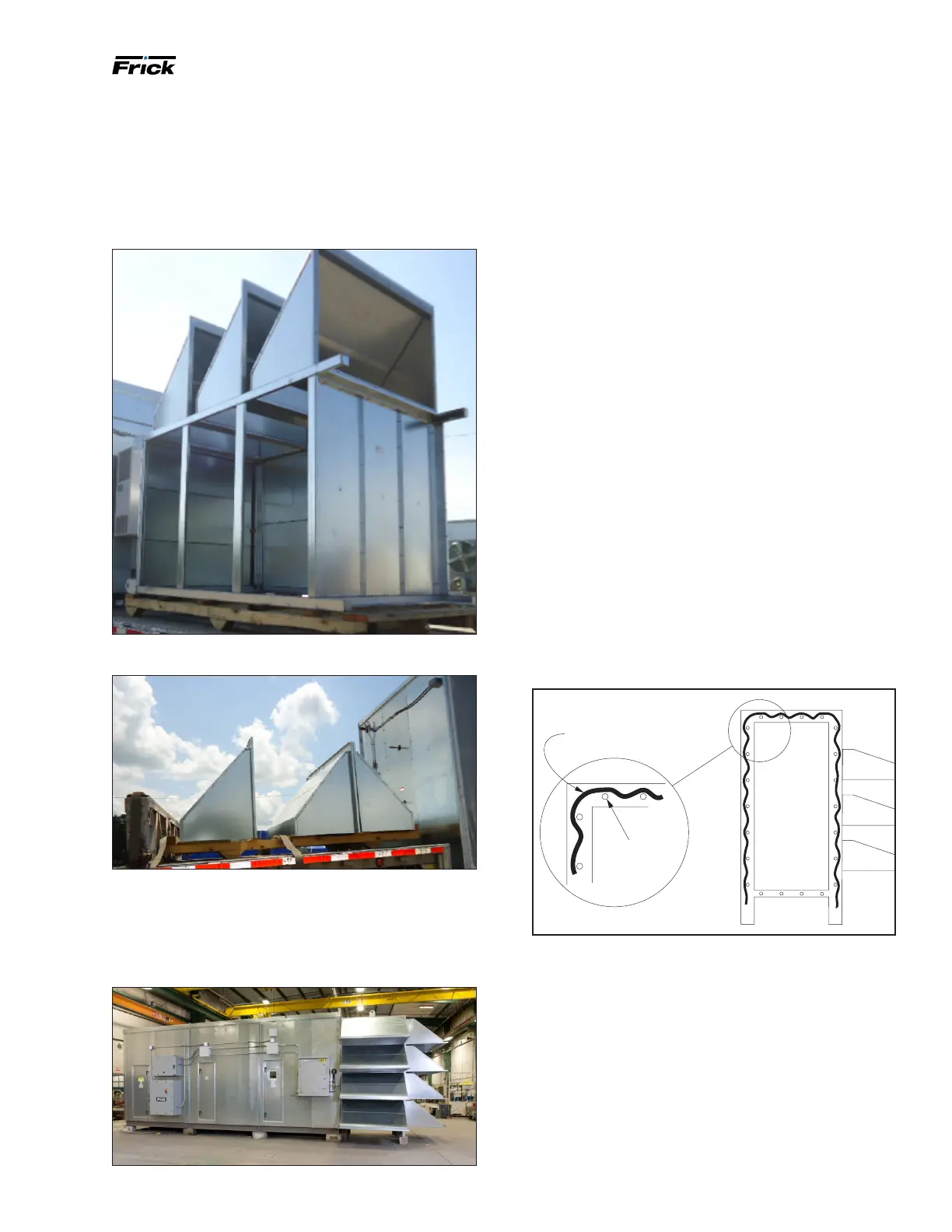

Figure 26: Applying caulk to plenum

Fresh Air Plenum Caulking

Factory Drilled

Tapper

Screw Holes

Site Applied Caulk to Seal the

Plenum to the AcuAir Unit

7. Using a crane, lift the plenum with mounted hoods

into position for attaching to the AcuAir

®

unit. The four

alignment tabs are intended to guide the hood into

position horizontally.

8. Position the two inner legs under the plenum into

the two attachment brackets and insert the four bolts

through the brackets and legs. This secures the plenum

in position vertically. The two outer legs must rest

securely on the additional site support.

Loading...

Loading...