✩ The knife is driven by the air cylinder. Therefore, relieve the air

pressure before adjustments.

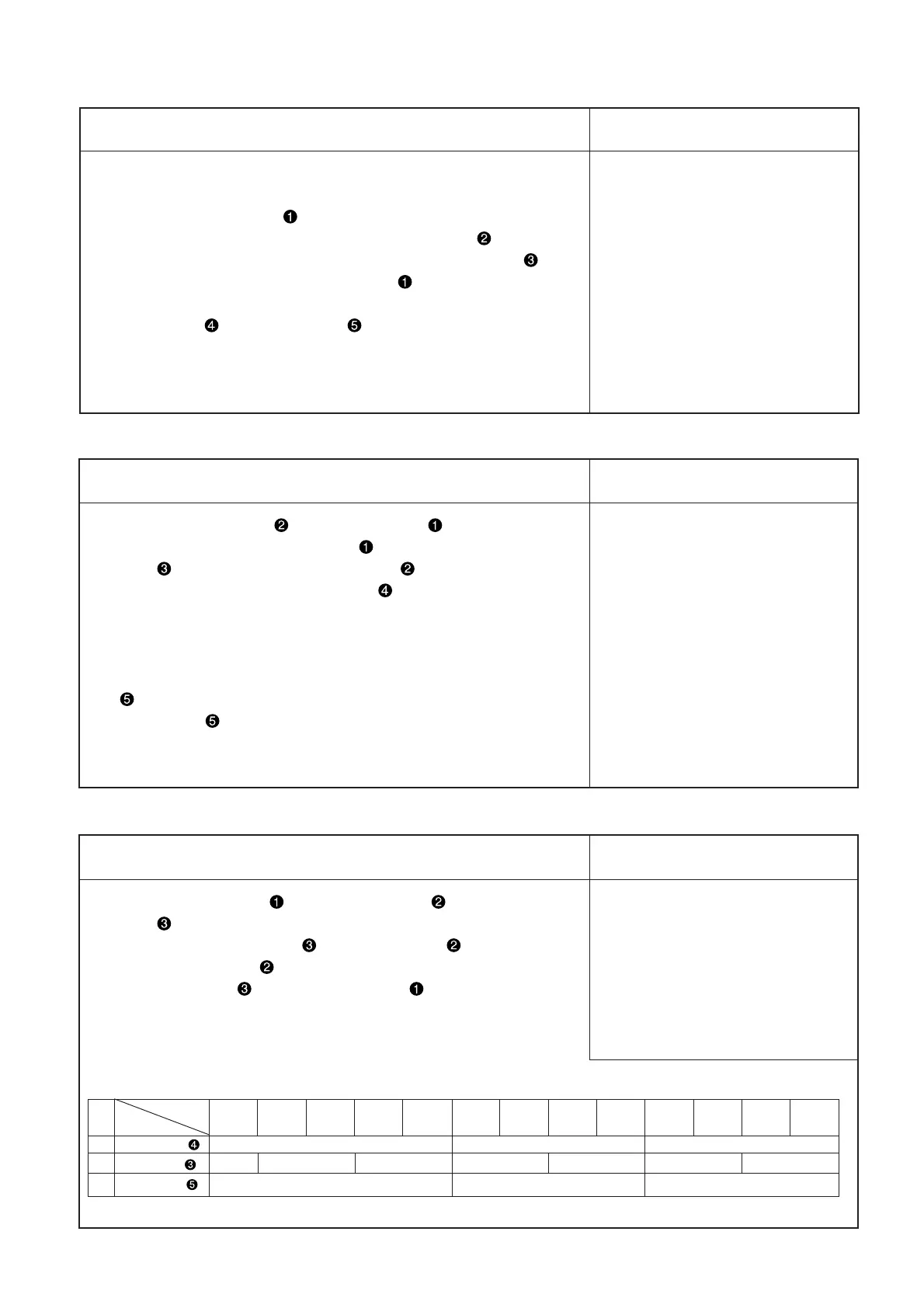

1. Loosen two setscrews and maintain the clearance toward the

throat plate at 5mm in the state that the moving knife is advanced

to the extreme front. Adjust the distance toward the needle to 30

to 32 mm and tighten the two setscrews .

In this case, confirm that a proper clearance is secured between the

center knife and the spreader .

– 8 –

1. Loosen two setscrews of the counter knife and push both right

and left blades of the counter knife uniformly against the moving

knife . Then tighten the two setscrews again.

2. Check the motion of the cylinder shaft . Confirm that it can work to

accomplish cutting assuredly at 17.6N (1.8kgf) or less.

3. After thread cutting, the holding force for needle thread clamp is

more than 2.9N (300g) both right and left.

In the case when this force is not secured, select an adequate spacer

.

[The spacer has four types of thickness: 0.2mm, 0.4mm, 0.6mm,

and 0.8mm]

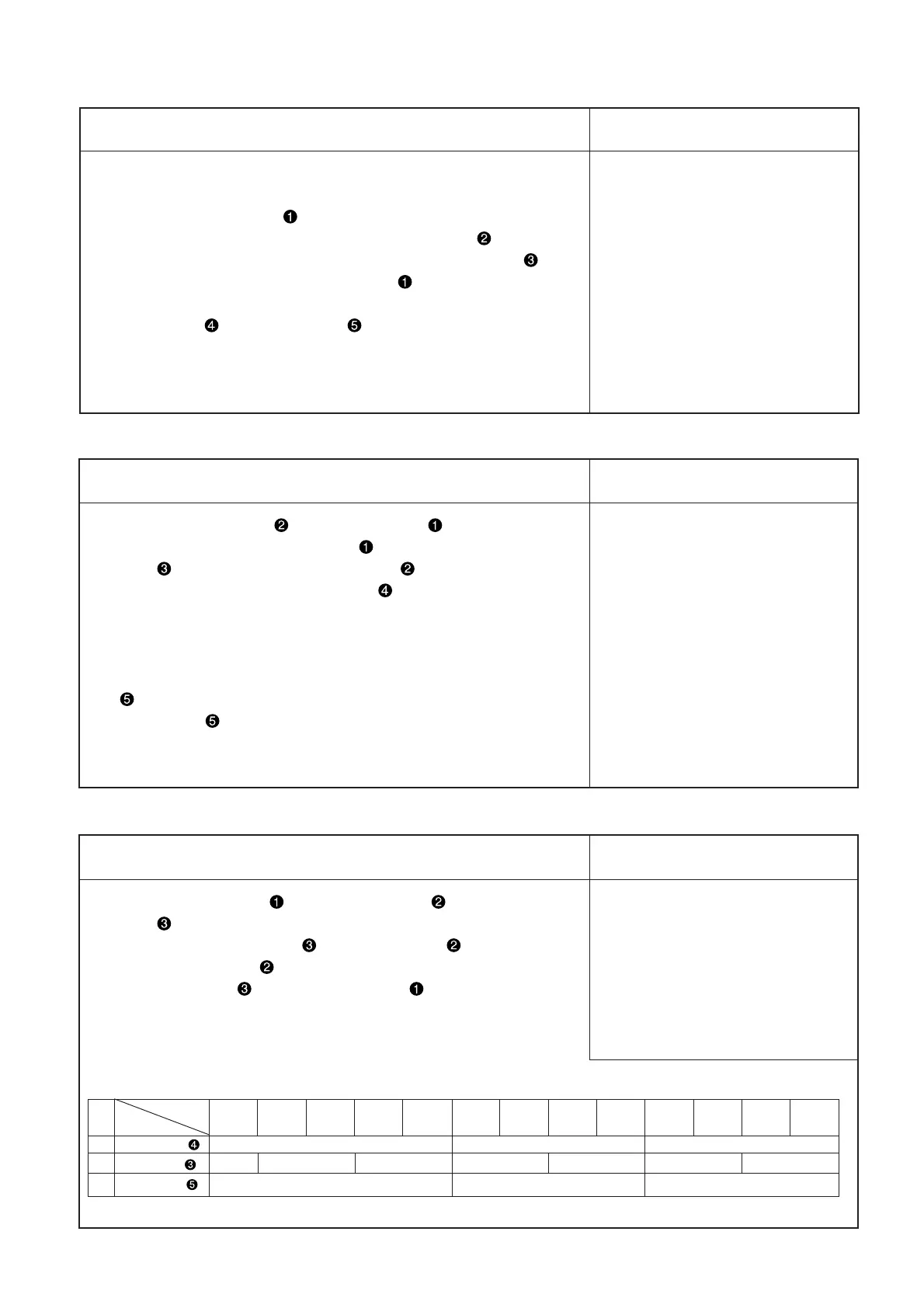

1. Loosen the setscrew and remove the pin . Then, the moving

knife can be pulled off downwards.

2. Install a new moving knife and insert the pin .

At that time, the pin should be held almost in the same plane of

the moving knife . Tighten the setscrew .

* The needle thread trimming unit has some mounting parts that can

change with the gauge size. Refer to the table below for details.

No. 8mm 10mm 12mm 14mm 16mm 18mm 20mm 22mm 24mm 26mm 28mm 30mm 32mm

1 Counter knife 16409906 16411308 40039788

2 Moving knife

40033814

40023020 40033809 40033810 40033811 40033812 40033813

3 Clamp plate 40033815 16411407 40039783

Size

Name of parts

Adjustment Procedures Results of Improper Adjustment

Adjustment Procedures Results of Improper Adjustment

Adjustment Procedures Results of Improper Adjustment

Loading...

Loading...