Maintenance

10 --- 58

10.4 Internal Heat Recovery Maintenance (option W2 / W3)

Pre---condition: Machine switched off.

Mains isolator locked off

Machine cooled down.

Deposits in the heat exchanger in machines with heat recovery systems can adversely af-

fect heat transfer.

Check the heat exchanger regularly for leaks and contamination. Frequency of checking is

dependant on the characteristics of the heat transfer medium.

Contamination

Have an authorised KAESER service agent clean the heat exchanger as soon as a

pressure drop in the heat transfer medium is detected.

Leakage

If a leak occurs, cooling oil can flow into the heat transfer medium as pressure the cooling

oil circuit is generally higher.

Check the heat exchanger visually for leaks.

Have an authorised KAESER service agent check the heat exchanger for internal leaks

at least once a year.

10.5 Air Filter Maintenance.

Material: Compressed air for blowing out

Spare parts (as required)

Pre---condition: Machine is switched off

Mains disconnect is locked out

Machine is cooled down.

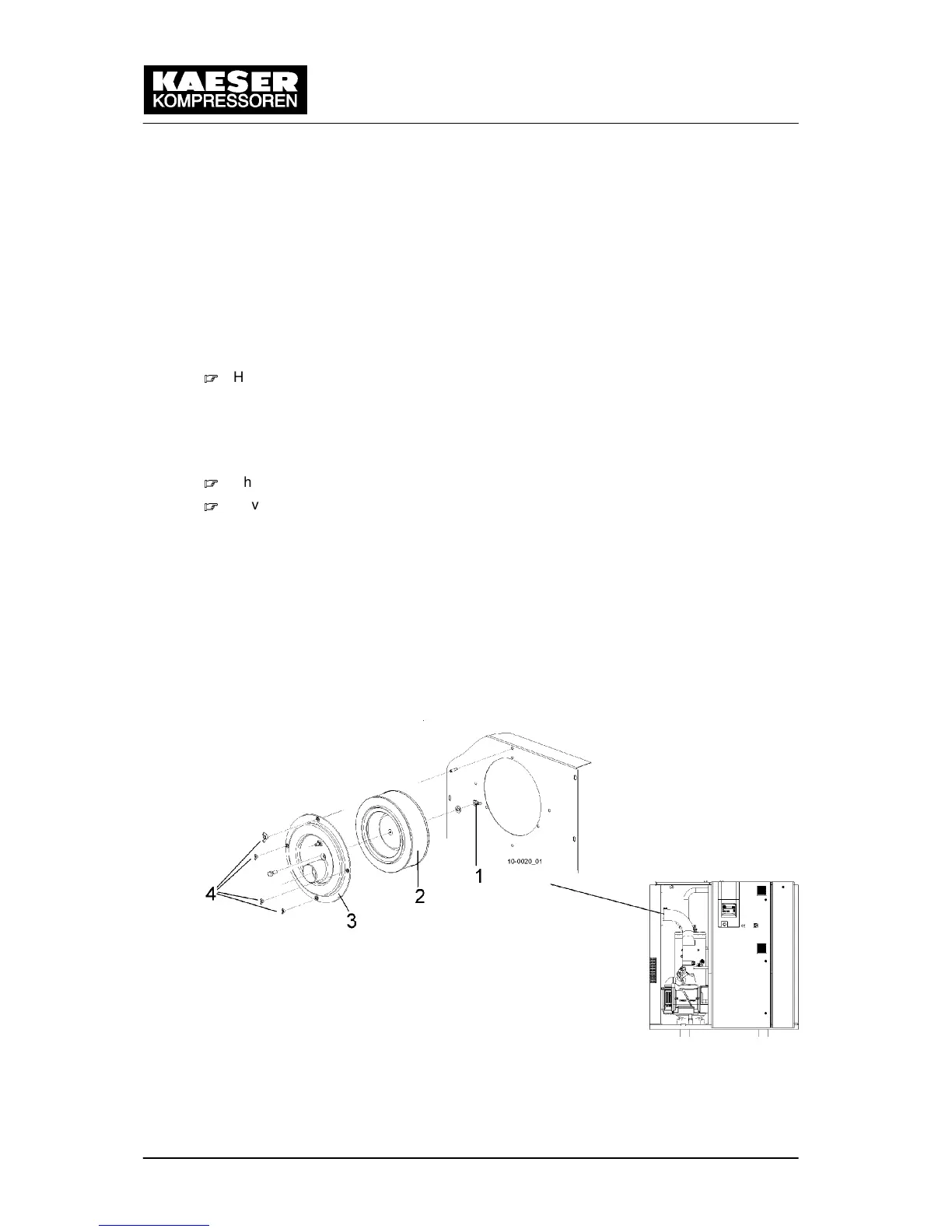

Fig. 22 Air filter maintenance.

1 Nut 3 Cover

2 Air filter cartridge 4 Nut

Loading...

Loading...