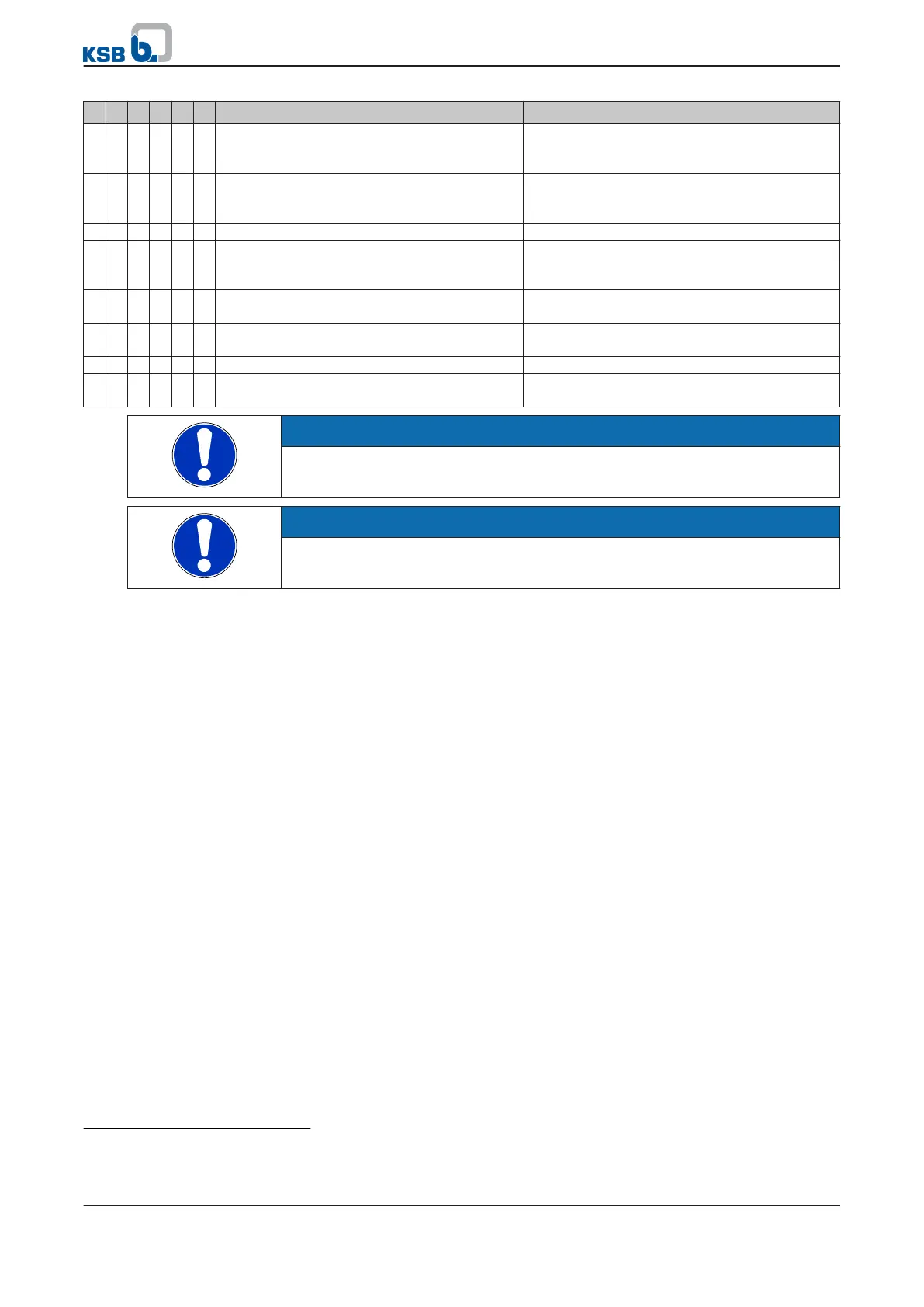

A B C D E F Possible cause

Remedy

5)

- ✘ - - - - Water level in the tank too low during

operation

Check level sensor.

Check parameters. If necessary, repeat

parameterisation.

✘ - - - - - Temperature sensor in the winding has

tripped the pump because of an excessive

temperature rise in the winding.

The motor will re-start automatically once the

unit has cooled down.

- - ✘ - ✘ - Defective radial bearing in the motor. Contact KSB.

✘ - ✘ - ✘ ✘ Cutter is blocked (on US/UZS)

- Excessive solids content

- Impermissible solids

Unblock the cutter (⇨ Section 8.2.3 Page 43)

- ✘ - - - ✘ Deposits in the collecting tank Clean the collecting tank; in case of greasy

deposits, fit a grease separator.

- - - - - ✘ Check valve does not close tightly. Clean the check valve, screw the lifting screw

back as far as it will go.

- - - - ✘ - System-induced vibrations Check the flexible pipe connections

✘ - - - ✘ ✘ Defective level sensor Check level sensor. Clean or replace as

necessary.

NOTE

After any fault or malfunction, carry out a visual and functional inspection of the

lifting unit.

NOTE

If the lifting unit has been flooded, always carry out an inspection.

5)

The pump pressure must be released before attempting to remedy faults on parts which are subjected to pressure.

Disconnect the pump from the power supply!

9 Trouble-shooting

mini-Compacta

53 of 86

Loading...

Loading...