8.7 Tightening torques

Component Max. tightening torque

Rotating assembly 01-44 on tank 6 Nm

Plate 185 on tank (US/UZS) 6 Nm

Level sensor 81-45 on tank 2 Nm

Check valve 747 on tank 6 Nm

Motor housing 811 on casing cover 6 Nm

Lantern 343 on casing (US/UZS) 12 Nm

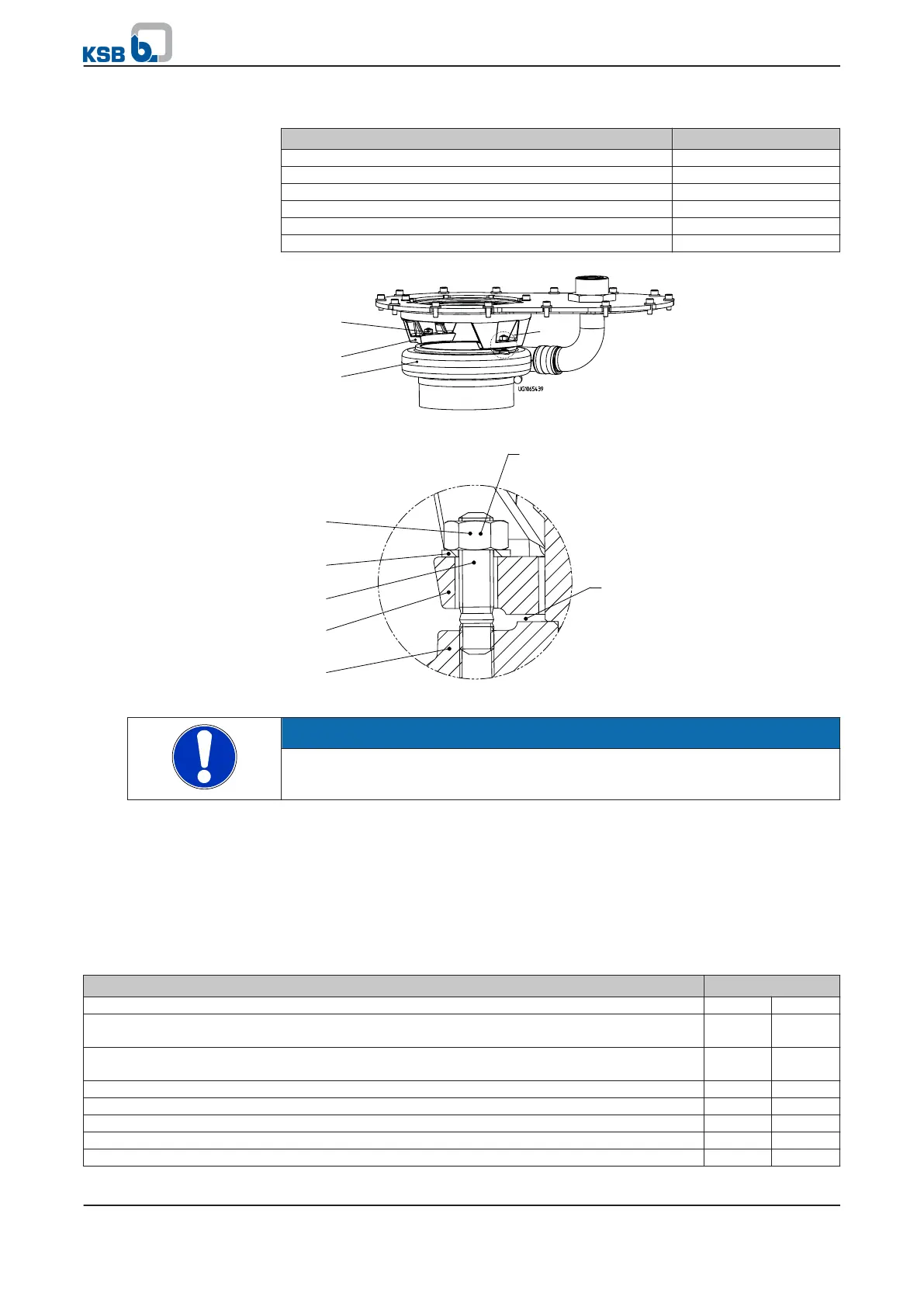

2x 920.03

2x 550.03

2x 902.03

343

100

920.03

550.03

902.03

343

Z

12 Nm

100

Z

↻

Ⓐ

Fig. 32: mini-Compacta US100, UZS150

NOTE

Fit lantern 343 observing clearance Ⓐ.

8.8 Disposal/recycling of the lifting unit

Lifting units consist of materials that can be separately recycled.

Plastic components are marked in accordance with ISO 11 469.

8.9 Checklist for commissioning/inspection ➀ and maintenance ➁

Table 20: Checklist

Actions Required during

Read the operating instructions. ➀ ➁

Check the power supply.

Compare the actual data against the name plate data.

➀ ➁

Check the direction of rotation (three-phase units). (⇨ Section 5.7 Page 25)

Then check that screw plug 903.1 is firmly seated.

➀ ➁

Check the earth conductor to ensure that it functions properly (to EN 60 439). ➀ ➁

Check winding resistances. ➁

Check insulation resistances. (⇨ Section 8.2.2 Page 43) ➁

Replace bearings, if required. ➀ ➁

Change the oil in the oil reservoir, if required. ➀ ➁

8 Servicing/Maintenance

50 of 86

mini-Compacta

Loading...

Loading...