28

.,

NOTES ON MAINTENANCE

Reg

ulating

valv

e

~-rr.t1¥"1kirnri-.,1riwkor:ul.ol

l

1M.deltM~~nir.

padlkm~ n hlhliJICilal. Tot

ibflOM<li,on

111rt~1$cn1N

right

sld•1ndlh1plasllcwra.p

llJ!fltl:tla011LnOll"!111311.

- When checking the valve clearance, the v- Drive

belt.

roller

alve gear phase marker must

be

aligned a- -

It

is

recommended

that

6000

km

first

check

whether

ccording to the above instructions.

- Use the thickness gauge to check whether

the clearance between the valve and the a-

djusting gasket confonns to the specified

value. If the inlet and exhaust valve clear-

ance is different from the

spedfied

value b-

elow, loosen the locknut

as

shown in the fi-

gure and adjust the valve clearance.

Inlet valve(not started

an

d state of cooling):

0.10mm

Exhaust valve (not started and state of co-

oling): 0.15mm

_/"'

the transmission belt

ball

slider

is

damaged.

•

Belt

detection:

• Stan

dard

Value:

21.3±02mm

;

• Limit

use

width:

19.5mm;

• urnt use

crack:

Tear

to

core

wire

position;

- More than 10,000

km

can be replaced belt;

-

Driving

wheel detection:

- Ball

standard

cfam

e1er.

¢

21

±

0.1

nvn

..

- Minimum allowable

ball

d'iameter:

¢ 20mm(No met-

al

lining

is

allowed

to

leak

out

of

theedge

and

the

pr-

essing

end)

.

- Nylon slider opening;;::

4.7mm

need to change.

-

It

is recommended that 12,000to 15,000

km

of ball be replaced.

-

Ball

replacement assembly requirements (must be

assembled according to

this

requirement).

Precautions

for

engine maintenance

, .

When

starting the engine,

th

e thrott!e

shOUd

beg

-

ently operated

to

st

art

the engine for 30-60s,

and

the-

n

the

coofe

r should be mode

ra

tely opened

to

start

the

eng

ine.

Do

not

accelerate immediately after starting,

and accelerate after 1-3min of

runni

n

g.

2. Wh

en

starting

by

pedal, the starting time should

n-

ot

ex

ceed

5s ( excluding auxiliary time

).

The

starting

lever should

be

a

bl

e

to

bounce

back

fl

exibl

y after

pre-

ss

ing.

3.

Dur

ing

electrical start-up, the starting time should

not

exceed

5s,

and

the

starting time should

be

10

se-

conds

apart. If the starting

time

cannot

be

started for

5 consecutive times,then

need

check

for

no

fault It

ls

strictly prohibited

to

press the start

ing

button after

sta-

rting.

4. After

the

engine starts nonnally,

Idle

running for 3

-5

seconds.

Let

the

engine lubrlcate before driving,

At

the

same

time, attention

should

be

paid

to

avoid

high

speed

and

heavy

load

operation before the engine

Is

preheated.

S.

The

new machine is mounted

on

the

motorcycle

after

the

first

1,000

kilometers

of

driving,

It

cannot

op-

erate

at

high

speed

for

long

periods

of

time,

nor

can

It

rotate

beyond

its

maximum

speed

of

BO

.

Do

not ope-

rate

the

throttle valve in

run

open

rondition, after 500

kilometers, a repair should be carried out

to

compen-

sate

for

the

sl

ight wear and

tear

In

the

run-in

period,

so

as

to ensure the good perfonnance

ol

the

engi

ne

.

6.

Clean

the

oil /gas separator and check and clean

the

air filter every 2000 km,

the

main

purpose

is

to

r-

emove

the

oil

stored

in

the oil

and

gas separator, ch-

eck the sealing condition

of

each

binding

surface

of

t-

he air

filter,

and remove the

sand

and dust

on

the

air

filter chamber

and

filter element. When assembling,

pay attention to

the

sealing of each joint

face,

and

re--

place

or

repair the parts that have lost the sealing

fu-

nction

to

ensure

the

air filtration effect, prolong the

s-

ervice

life

of

the

engine piston block, effectively avoid

buming

oil

or power shortage.

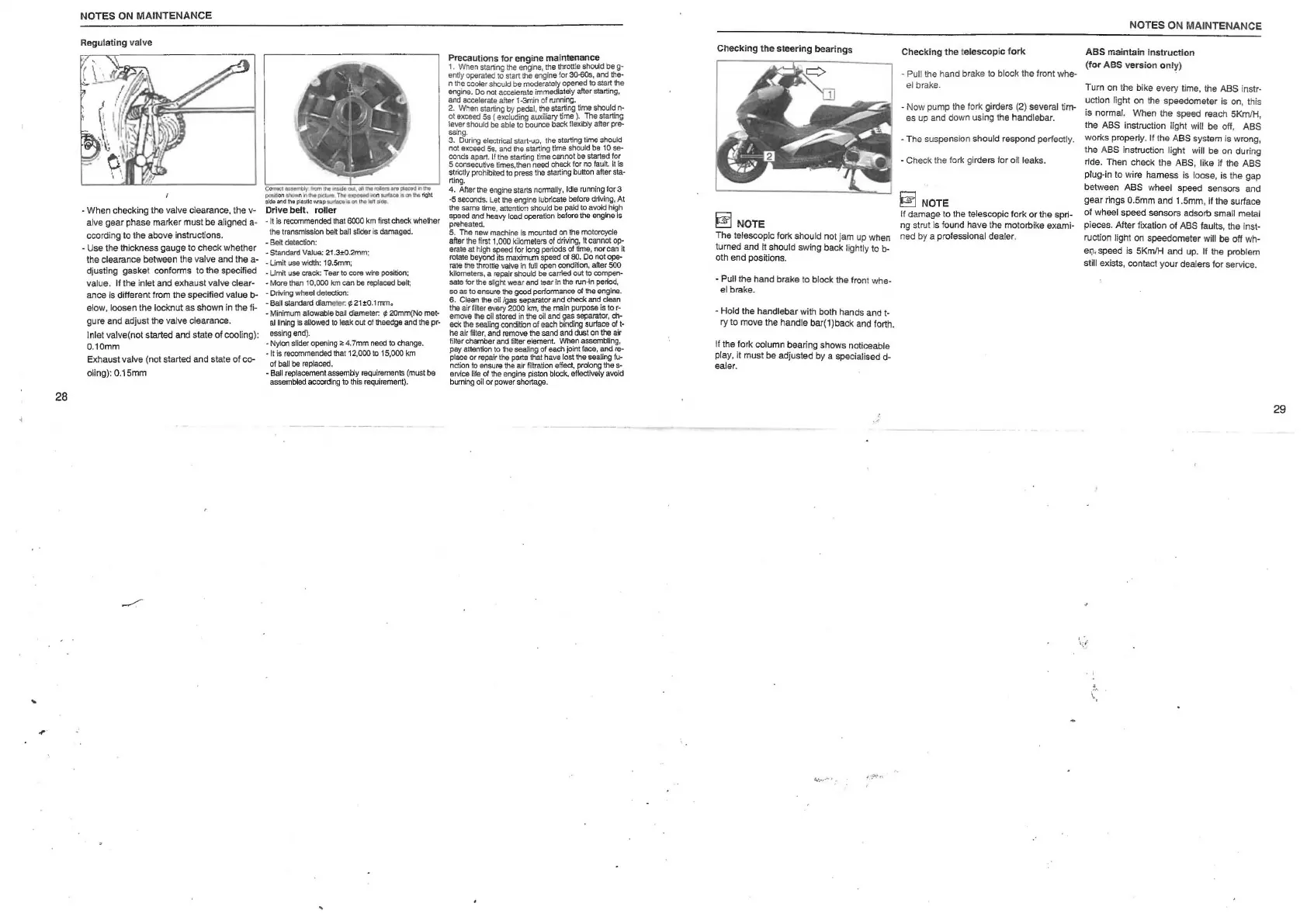

Checking the steering bearings

NOTES ON MAINTENANCE

Checking

the

t

elescopic

fork

ABS

maintain

instruction

(for ABS version only)

- Pull the hand brake to block the front whe- ·

el brake.

- Now pump the fork girders (2) several tim-

es up and down using the handlebar.

- The suspension should respond perfectly.

- Check the fork girders for oll leaks.

el NOTE

el NOTE

If damage to the telescopic fork

or

the spri-

ng strut is found have the motorbike exami-

The telescopic fork should not jam

up

when ned

by

a professional dealer.

Turn

on

the bike every time, the ABS instr-

uction right on the speedometer is on, this

is normal. When the speed reach 5Km/H,

the ABS instruction light will be off, ABS

works properly. If the ABS system

is

wrong,

the ABS instruction light will be

on

during

ride. Then check the ABS, like

If

the ABS

plug-in to wire harness

is

loose, is the gap

between ABS wheel speed sensors and

gear rings 0.5mm and 1.5mm, if the surface

of wheel speed sensors adsorb small metal

pieces. After fixation of ABS faults, the inst-

ruction light

on

speedometer will be off wh-

eQ

, speed is 5Km/H and up. If the problem

still exists, contact your dealers for service.

turned and it should swing back lightly to b-

oth

end

positions.

- Pull the hand brake to block the front whe-

el

brake.

- Hold the handlebar with both hands and

t-

ry

to move the handle bar(1 )back and forth.

lf the fork column bearing

shows

noticeable

play, it must be adjusted by a specialised d-

ealer.

4.

~•,

.....

'

,_,-:

~

~>,•

"

. ,

{:·

29

Loading...

Loading...