EN

2. Welding channel (job) selection. There are 10 memory channels available per USER channel.

There are 10 USER channels . If the channel is empty you can create a new (job) channel

by pressing the key below the LCD screen text stating NEW.

3. MENU button for entering the main menu list. Proceed following the LCD screen menu

guidance.

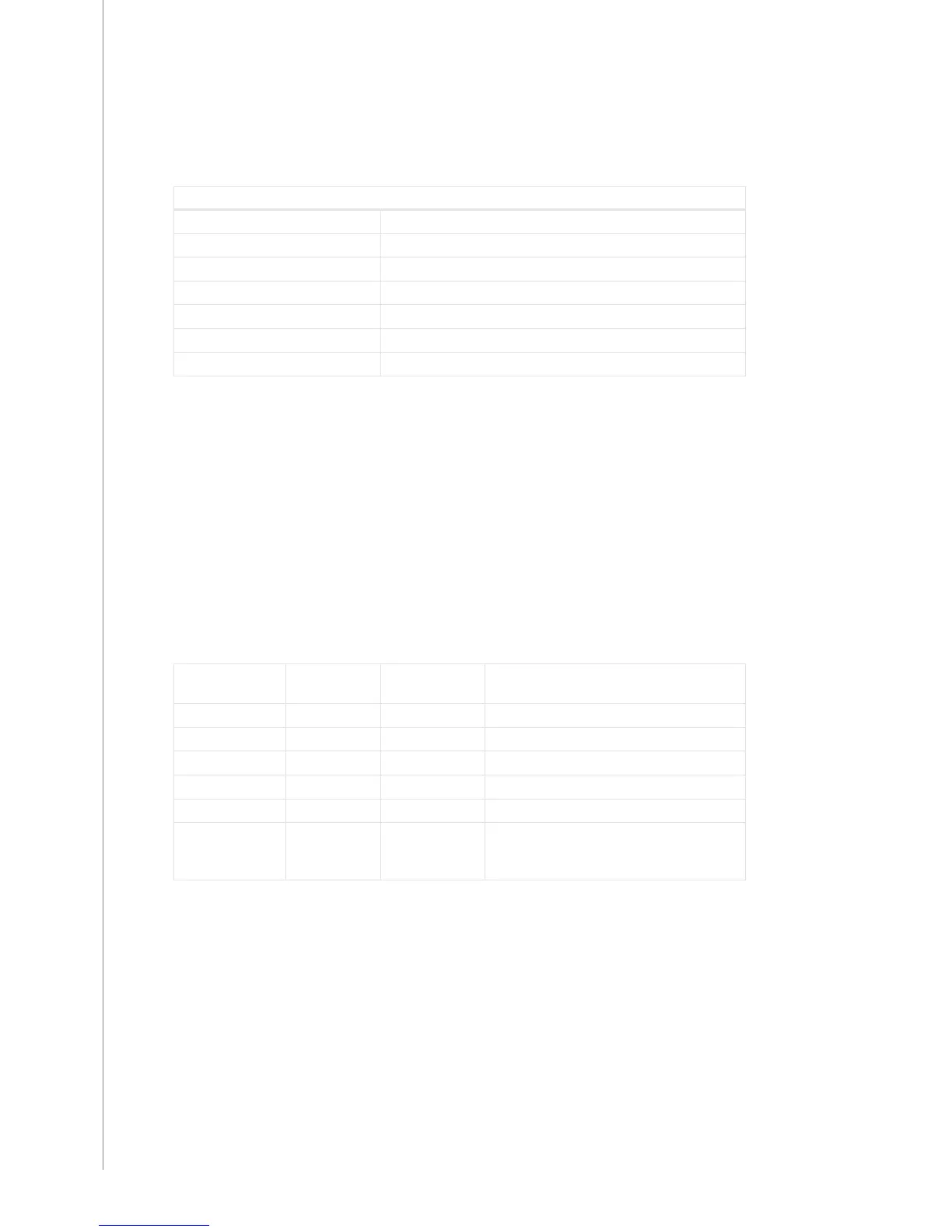

P65 main menu list

Edit Channel

for making changes to existing welding channel

User Identification

for selecting one user out of ten

Weld Data

for checking out the values of the last weld

System Config Menu

for device conguration and information

Language

for selecting your menu language

Select Feeder (WF#)

for selecting another parallel wire feeder as a setup target

MMA on/off

for activating electrode welding (licence needed)

Buttons in dierent situation (shortcut) include functions depending on menu/task.

4. Potentiometer for making adjustments to selected values

5. Up/down arrow keys for moving vertically in the menu structure

6. Pre-programmed menu shortcut keys

• F1 for displaying channel information

• F2 for selecting the USER

• F3 for selecting another parallel connected wire feeder sub system as a setup target.

7. LCD menu display

8. Soft key buttons. Function according to the menu location/task.

4.3 WELDING PARAMETERS AND FUNCTIONS

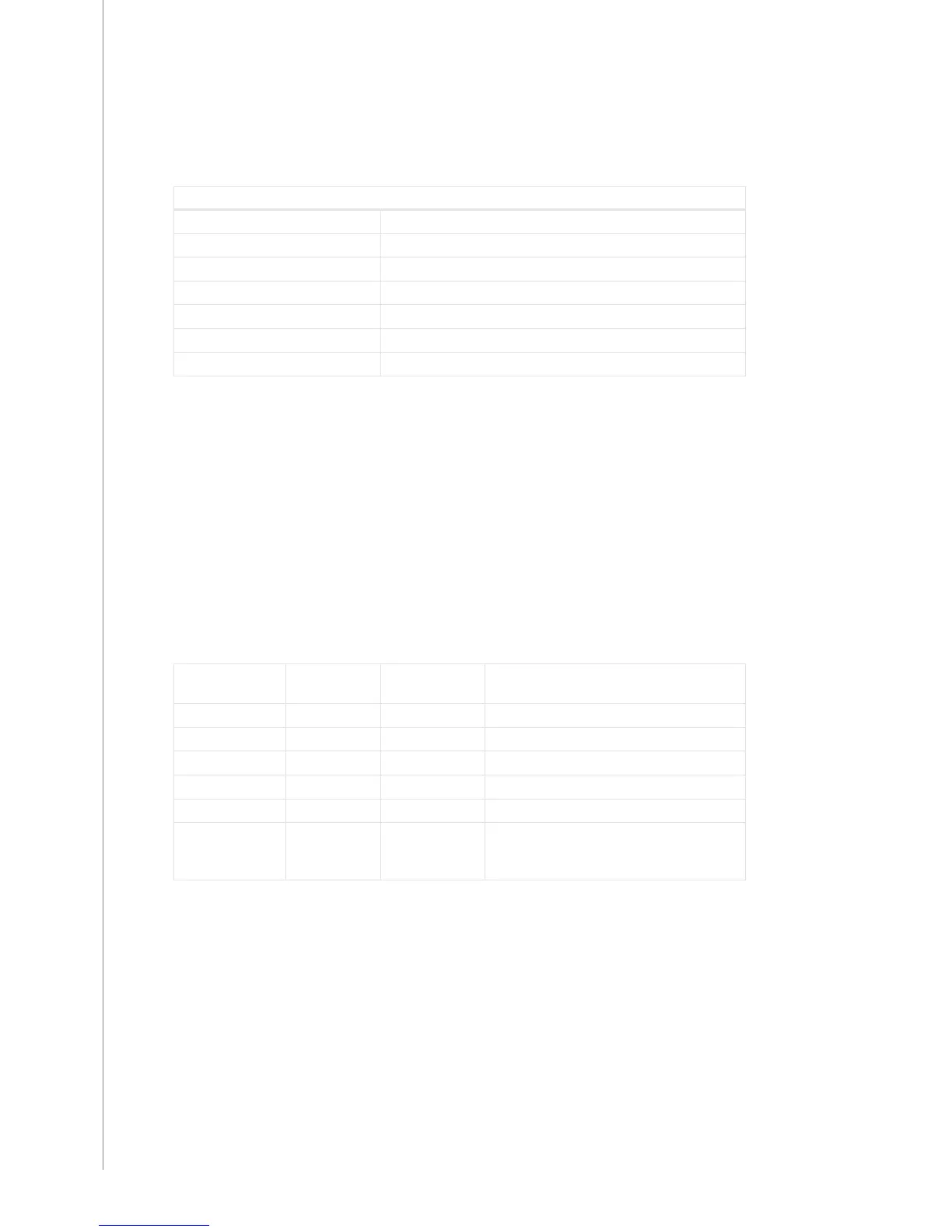

4.3.1 Welding parameters (In Edit Channel menu 2/6)

MIG

WFSpeed

0.7 – 25 m/min 0.05 m/min steps when WFSpeed < 5 m/min and

0.1 m/min steps when WFSpeed > 5 m/min

WFS-Max

Set the limit for maximum WFSpeed

WFS-Min

Set the limit for minimum WFSpeed

Voltage

8 – 50V 0.1V steps Controls the length of the arc

VoltageMax

Set the limit for maximum voltage value

VoltageMin

Set the limit for minimum voltage value

Dynamics

-9 ... +9 Factory setting is 0 Controls the short circuit behaviour of the arc. The lower

the value the softer the arc is. The higher the value the

rougher the arc is.

10

FastMig Pulse 350, 450 / © Kemppi Oy / 1110

Loading...

Loading...