Service manual Master S 400 and 500

11

Kemppi Oy

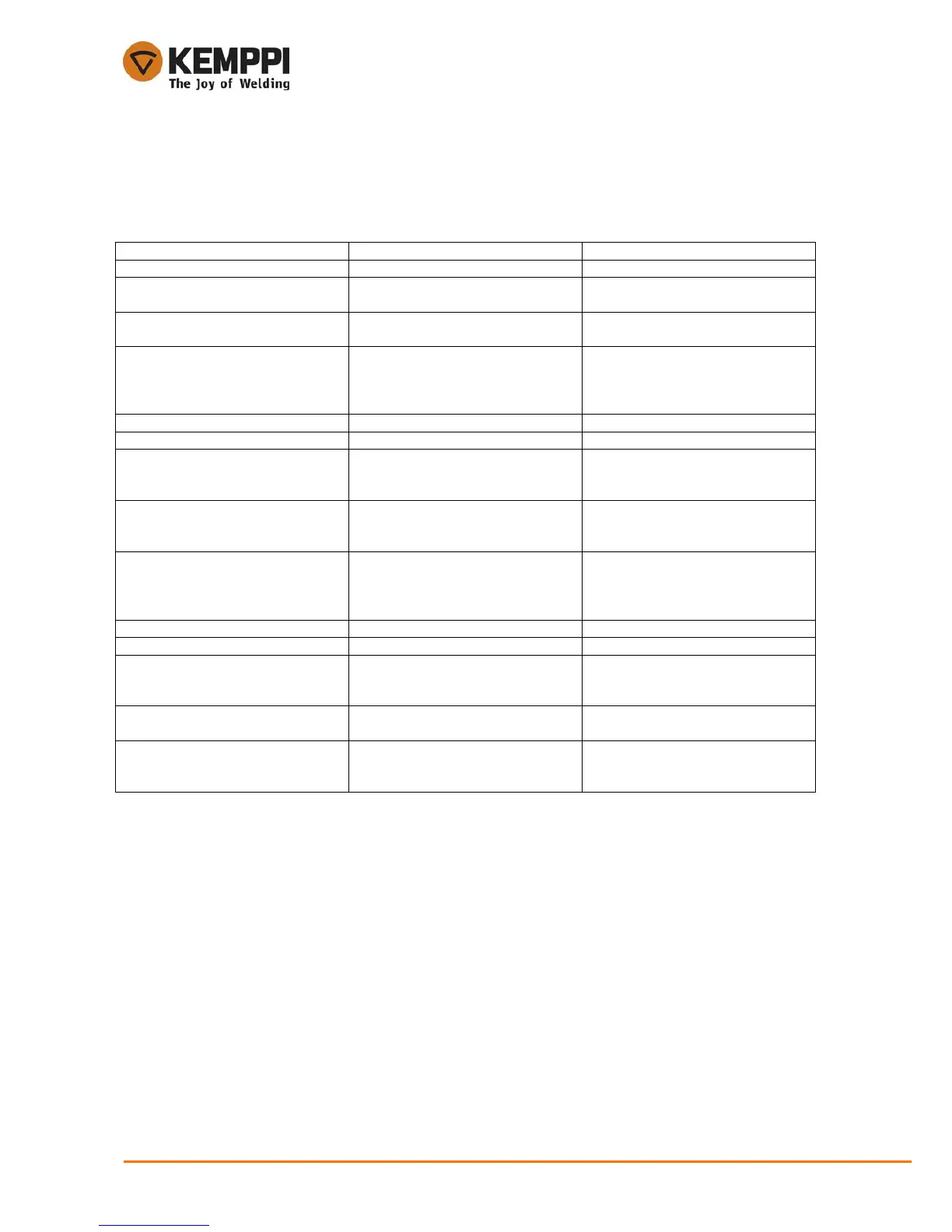

3.6.2. Error codes and error log menu

Machine can show several error codes and they are automatically saved to error log file. This log file can

save up to 10 errors.

Check the mains network

connection and fuses.

Check the mains network

connection and fuses.

Ensure free air flow. Let the

machine cool down.

Measure PTC value and ensure

it is not broken.

IGBT NTC overheat warning

Ensure free air flow. Let the

machine cool down.

Measure NTC value.

Ensure free air flow. Let the

machine cool down.

Measure NTC value.

Check the mains network

connection and fuses. If

connected to generator check

setup jumper Gen.

Machine is shut down because of

too long short circuit (over 20s) in

welding circuit.

Machine has panel that is not

compatible to machine version

There is no shunt resistor

feedback to machine control

card.

3.6.2.1. Using error log

Error log can be entered by pressing “Remote” button as long as text “ErL” appears in the display. Using

potentiometer error log can be rolled from 0 to 9. Error code is shown after the index number from E1 to

E14.

0 = latest error

9 = oldest error

Error codes from E1 to E14

If no error saved in the log -> E-

Loading...

Loading...