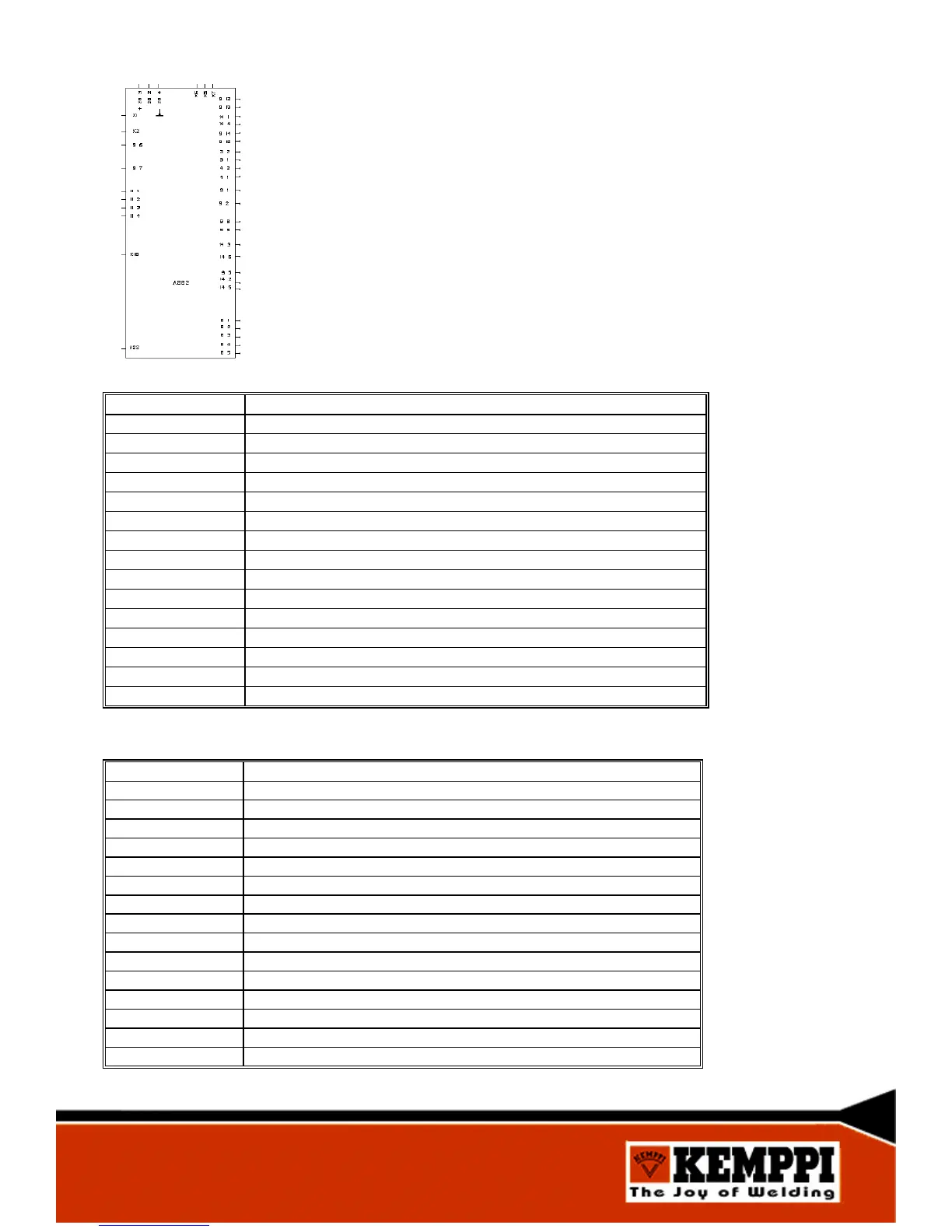

Control card A002´s functional blocks:

• PWM-development

• Primary IGBT control

• Current and voltage adjustment loop

• Aux. Voltages development + 5, ± 15, + 16 and + 24 V

• Secondary overvoltage watch

• Primary current limiting circuit

• Net overvoltage and undervoltage watch

• Fan control power stage

• Solenoid valve control power stage

• Cooling unit control power supply

Control card A002 functions / connectors

27

X1/1

Machine size detection (1600/2500)

X1/2

Set value from the remote controller

X1/3

Process selecting from the remote controller

X1/4

Overheat protections (PTC)

X1/5

Machine size detection (2000)

X1/6

Fan control

X1/7

Net voltage watch from the aux. Transformer T002 secondary

X1/8

-

X1/9

Welding current; DC+ or AC positive half cycles

X1/10

Welding current; DC- or AC negative half cycles

X1/11

Welding voltage; DC+ or AC positive half cycles

X1/12

Welding voltage; DC- or AC negative half cycles

X1/13

Net overvoltage watch

X1/14

Control amplifier (N6-A) output

X1/15

TIG-torch switch

X1/16

AC TIG auxiliary pulse control

X2/1 Solenoid valve

X2/2 TIG ignition spark control

X2/3 Set value from A001

X2/4 PWM enable

X2/5 Secondary IGBT control

X2/6 Secondary IGBT control

X2/7 + 16 V

X2/8 + 16 V

X2/9 + 5 V

X2/10 + 5 V

X2/11 GND

X2/12 GND

X2/13

Cooling unit start

X2/14

Stop-command from the cooling unit

X2/15

Inverter frequency 18/36 kHz

X2/16 Machine size detection (3500)

Loading...

Loading...