4-2 September 2004

Argonite

®

Engineered Fire Suppression System

38-KFSARG-000

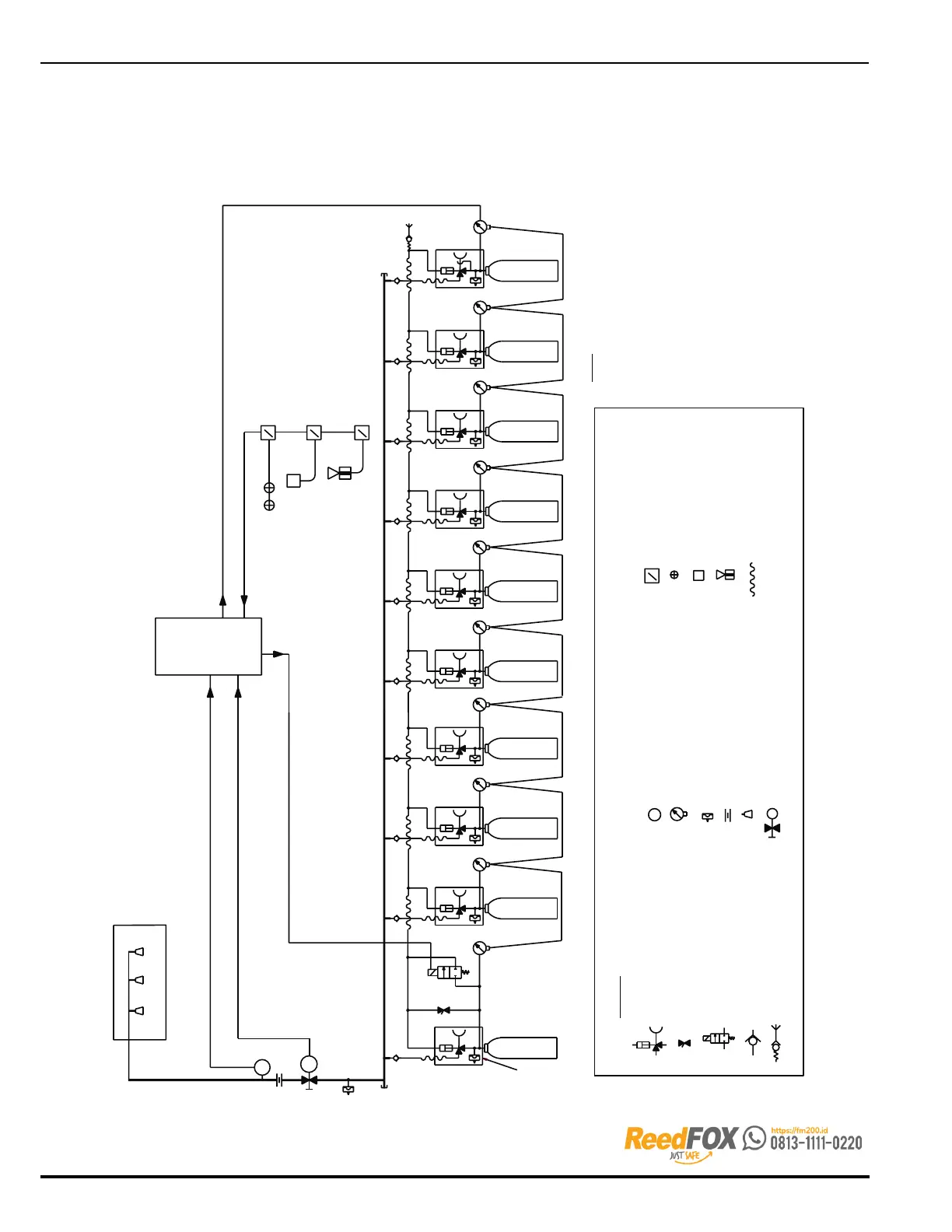

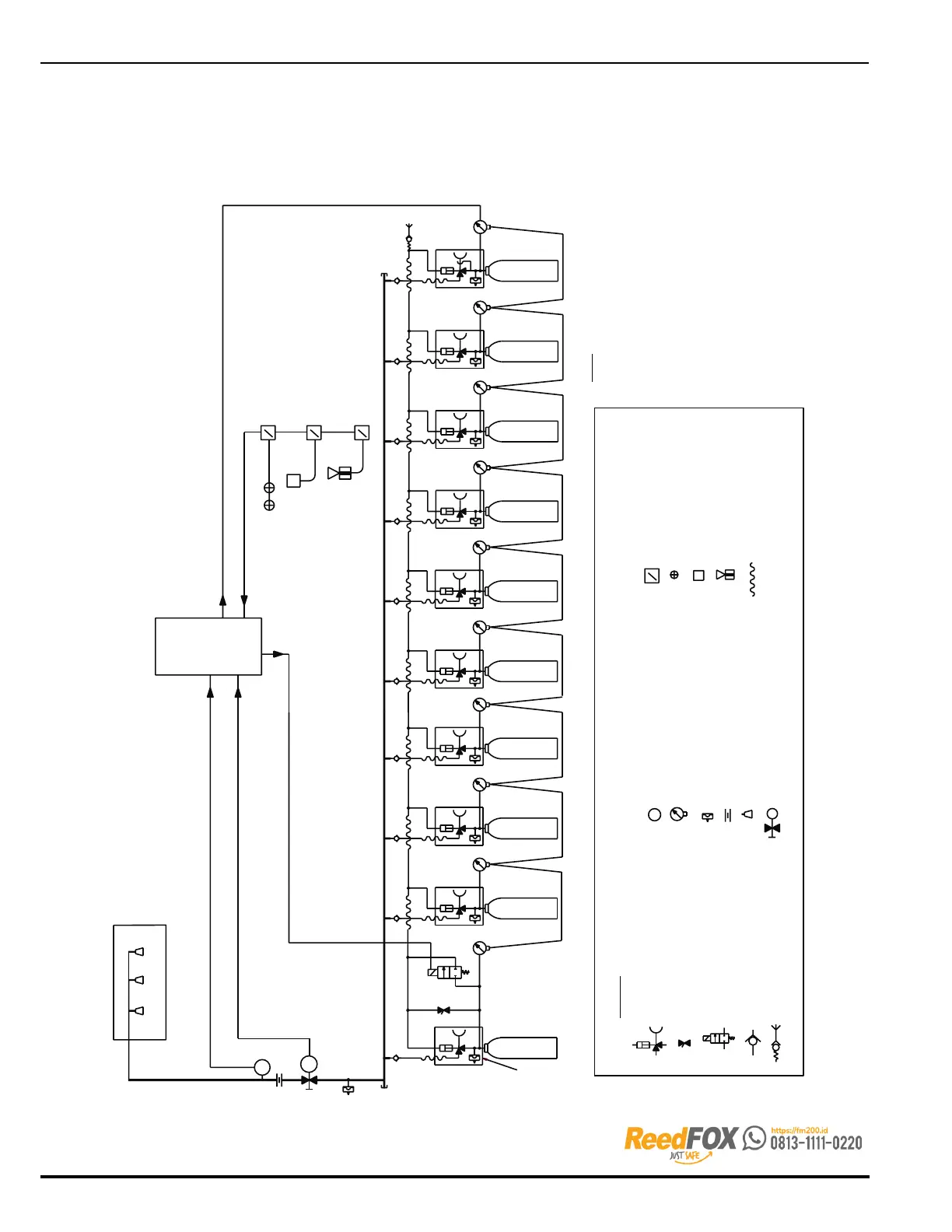

PILOT LINE BLEEDER/LEAK VALVE

MANUAL RELEASE VALVE

MANIFOLD CHECK VALVE

CYLINDER VALVE

N.C.

H

LEGEND

PRESSURE SWITCH, SYSTEM ACTIVATION

BURSTING DISC, 270 +30 BAR SETPOINT

B.D.

RESTRICTOR

NOZZLE

P.S.

DISCHARGE MANIFOLD

SLAVE

PILOT

SLAVE

SLAVE

ZONE 1

B.D.

N.C.

H

2

1

N.C.

B.D.

H

B.D.

H

B.D.

H

CONFIRMATION OF RELEASE

SLAVE

SLAVE SLAVE

SLAVE SLAVE SLAVE

ALARM

AND

CONTROL

PANEL

B.D.

H

B.D.

H

B.D.

ZONE 1 ACTIVATION

MONITORING PRESSURE

H

B.D.

H

B.D.

H

B.D.

H

P

MANUAL PULL STATION

ALARM HORN/STROBE

DETECTORS

JUNCTION BOX

P

DETECTION/ANNUNCIATION

PRESSURE GAUGE, INDICATING 145-300 BAR,

WITH LOW PRESSURE SWITCH, 160 BAR SETPOINT

N.O.

SUPERVISION OF LOCKOUT VALVE

ISOLATION/LOCKOUT VALVE (NORMALLY OPEN)

WITH SUPERVISORY LIMIT SWITCH

L.S.

OUTLINE

OF VALVE

2 WAY SOLENOID VALVE, 24 VDC

14W MAX. ONE VALVE FOR EACH 100 CYLINDERS

(OPTIONAL)

FLEXIBLE HOSE

PIPE SIZING TO BE DETERMINED BY

KIDDE FIRE SYSTEMS ARGONITE FLOW SOFTWARE.

PIPE SCHEDULE ACCORDING TO ASTM B31.1 (POWER PIPING CODE).

B.D.

N.C.

2

1

REQ'D IF LOCKOUT VALVE IS USED

(10 CYLINDERS)

B

J

B

J

B

J

J

B

L.S.

P.S.

Argonite

NOTES:

Argonite

Argonite

Argonite

Argonite

Argonite

Argonite

Argonite

Argonite

Argonite

Figure 4-1. Piping and Instrumentation Diagram for Single Hazard Argonite System

Loading...

Loading...