6-12 July 2004

Argonite

®

Engineered Fire Suppression System

38-KFSARG-000

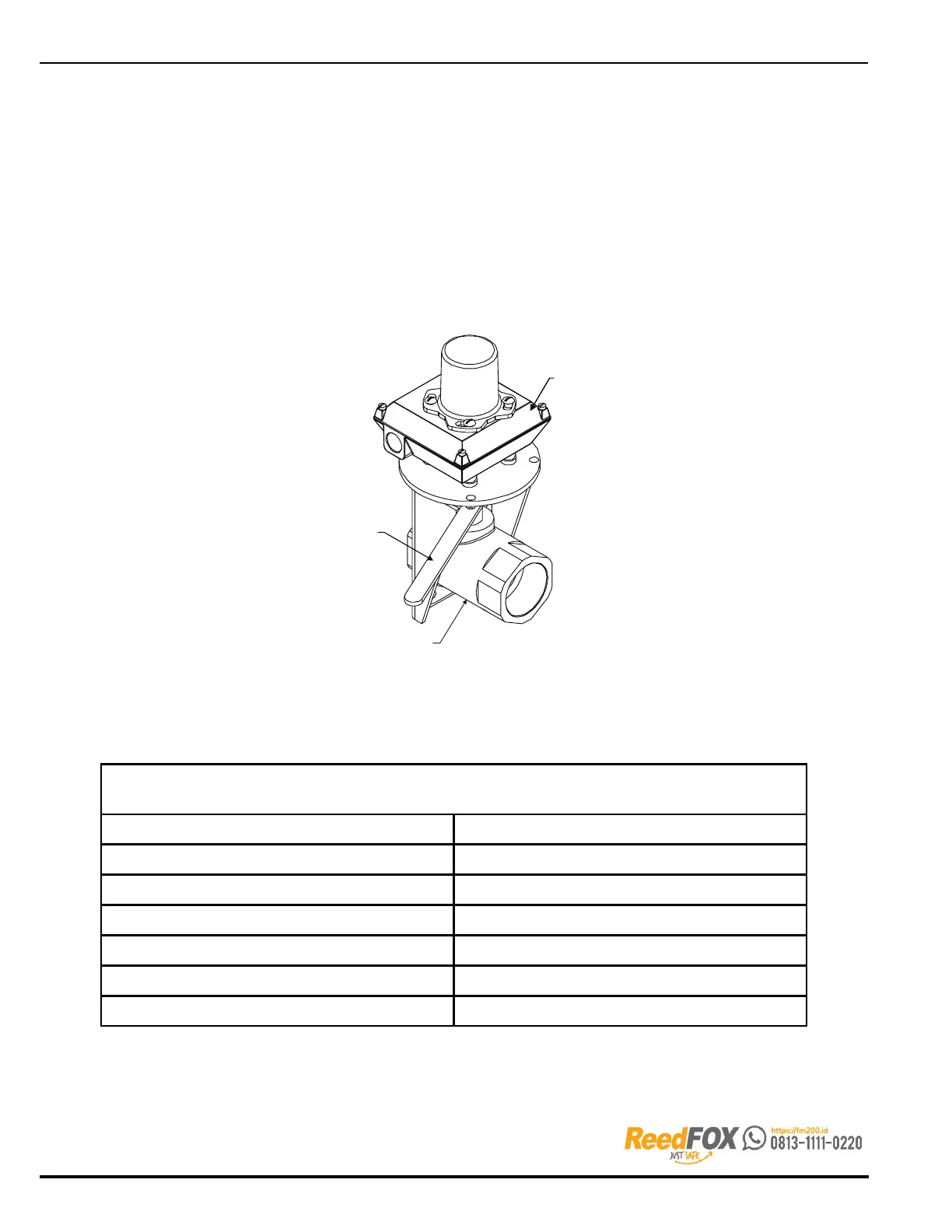

6.6.3 Isolation (Lockout) Valve Assemblies

Isolation (lockout) valves may be installed for maintenance/service reasons; for multi-

hazard systems they are typically installed upstream of the selector valve as illustrated

in Figure 4-2. For single hazard systems, the isolation valves shall be located upstream

of the restrictor. These devices MUST be locked in the OPEN position whenever the

Argonite System is in operational/standby condition. When the discharge piping is being

serviced, these valves MUST be locked in the CLOSED position.

Isolation valve assemblies include a high visibility indicator and weatherproof limit switch.

The limit switch shall initiate a Trouble signal at the control panel when the ball valve

is in the closed position. All ball valves have a working pressure of 2900 PSI (200 bar).

When using isolation valves, a pressure relief valve should also be installed wherever

pressure could be trapped in closed sections of pipe.

LIMIT SWITCH

LOCKING HANDLE

HIGH PRESSURE

BALL VALVE

Figure 6-15. Isolation (Lockout) Valve, Typical

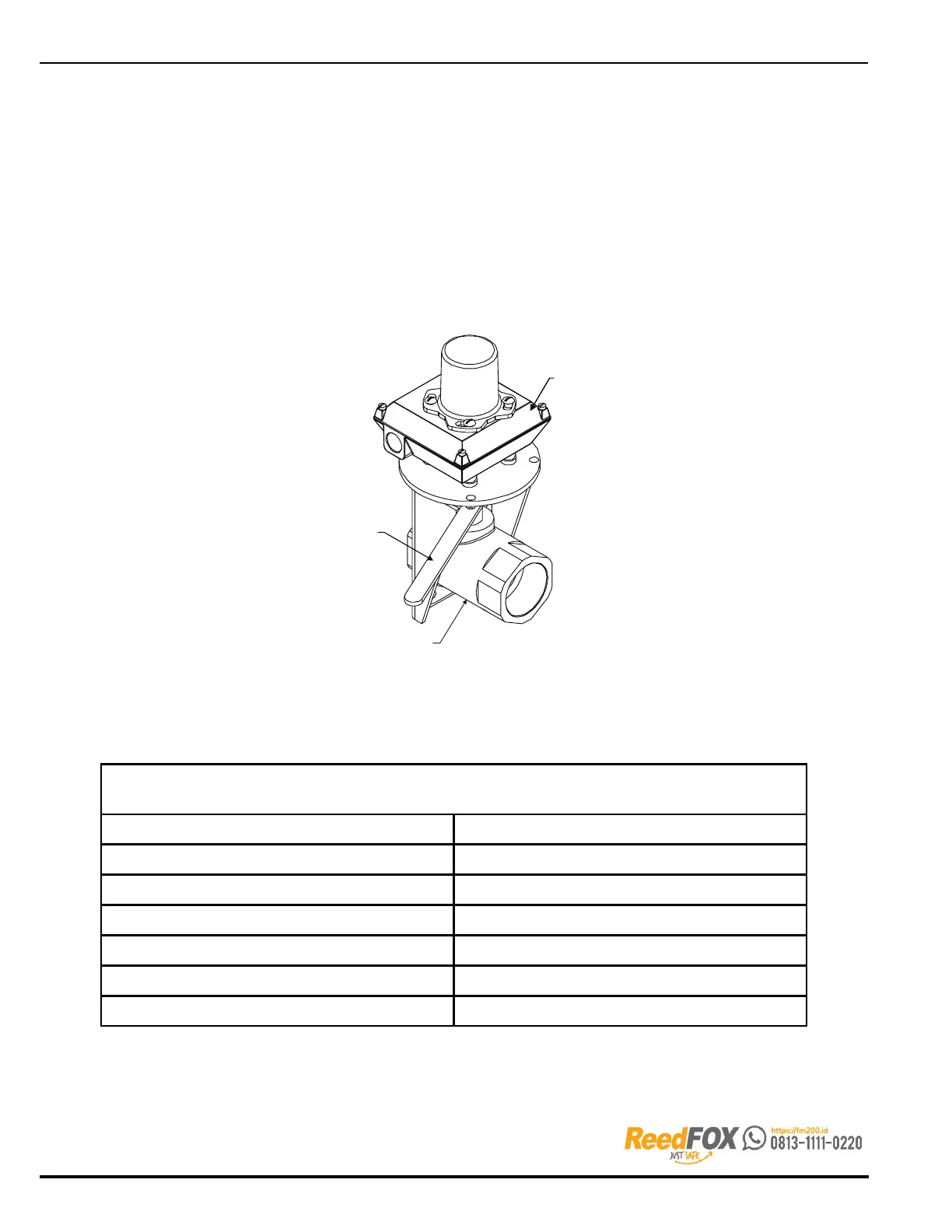

Table 6-8. Isolation (Lockout) Valve Assemblies

NEMA 4 and 4X

with Limit Switch, 2-SPDT

Part Number Size

38-509835-001 1/2 in.

38-509835-002 3/4 in.

38-509835-003 1 in.

38-509835-004 1¼ in.

38-509835-005 1½ in.

38-509835-006 2 in.

Loading...

Loading...