Chapter 8 Control Performance

8.1 Driver Performance Tuning

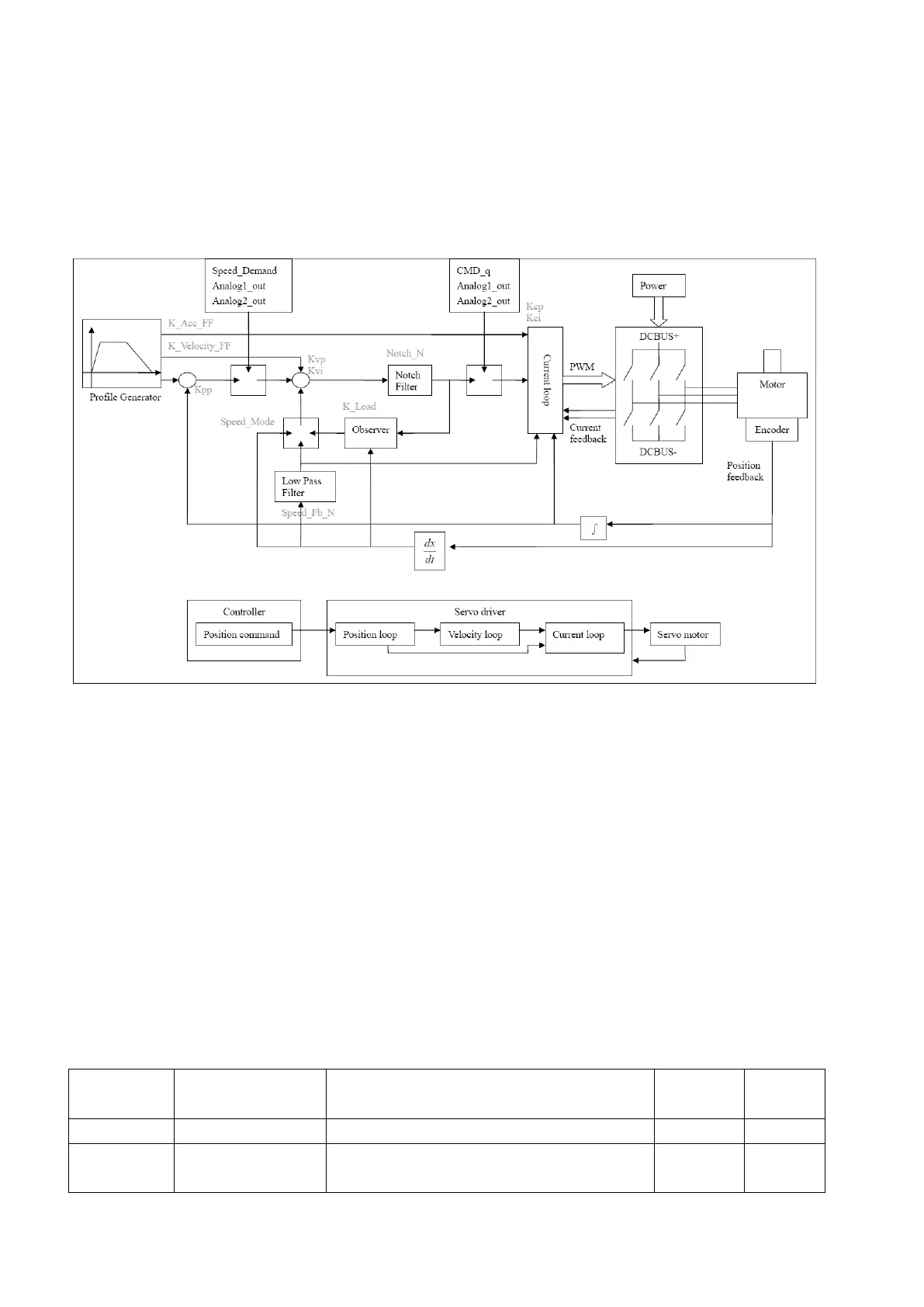

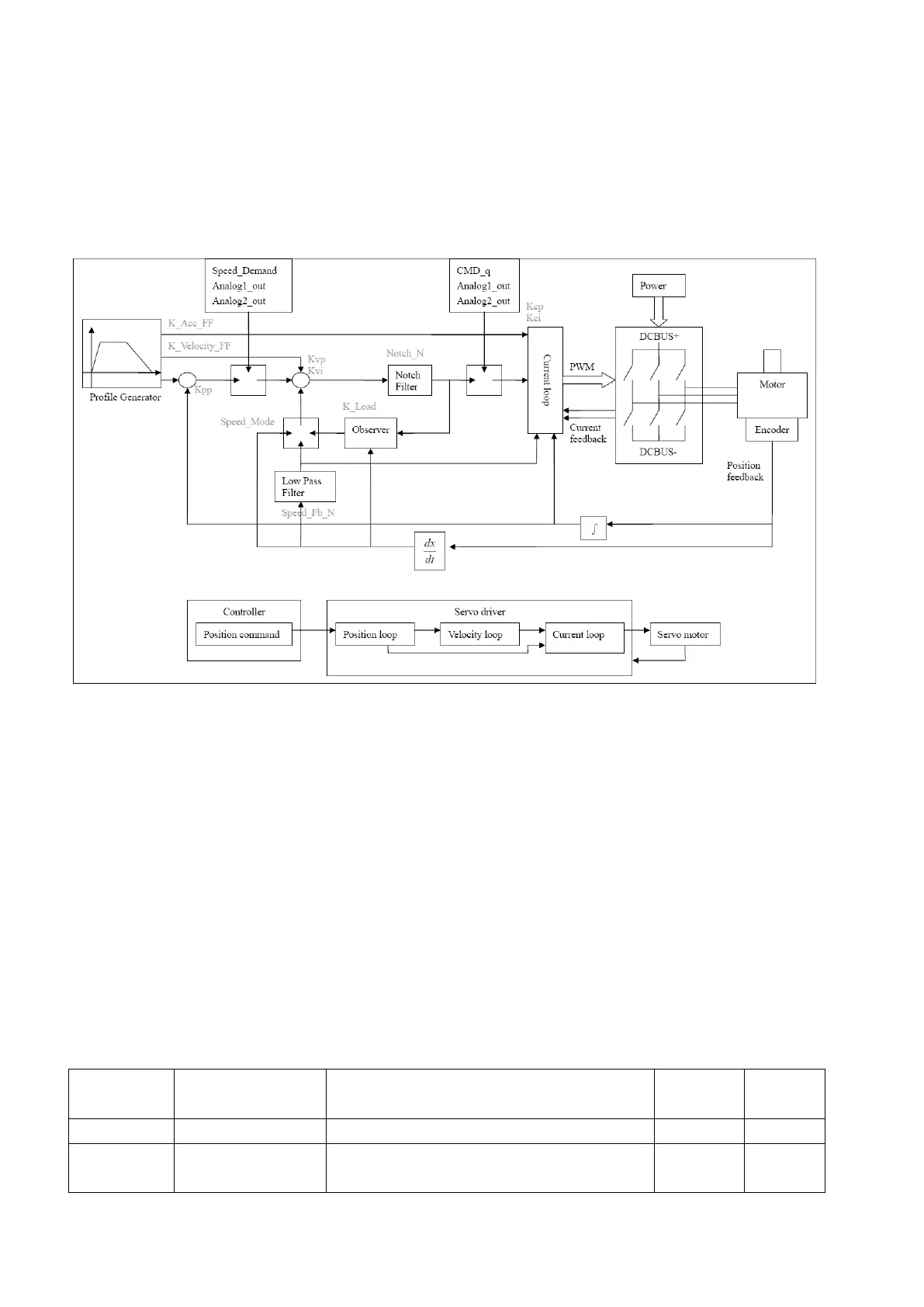

Fig. 8-1 Schematic diagram for control loop adjustment

As shown in Fig. 8-1, a typical servo system contains three control loops, namely, a position loop, a

velocity loop, and a current loop.

Current loops are related to motor parameters (optimal parameters of the selected motor are default for

the driver and no adjusting is required).

Parameters for velocity loops and position loops should be adjusted properly according to loading

conditions.

During adjustment of the control loop, ensure that the bandwidth of the velocity loop is at least twice of

that of the position loop; otherwise oscillation may occur.

8.1.1 Manual Adjustment

1. Parameters for velocity loop

Table 8-1 Parameters for velocity loop

Sets the response speed of a velocity loop

Adjusts speed control so that the time of

minor errors is compensated

Loading...

Loading...