26

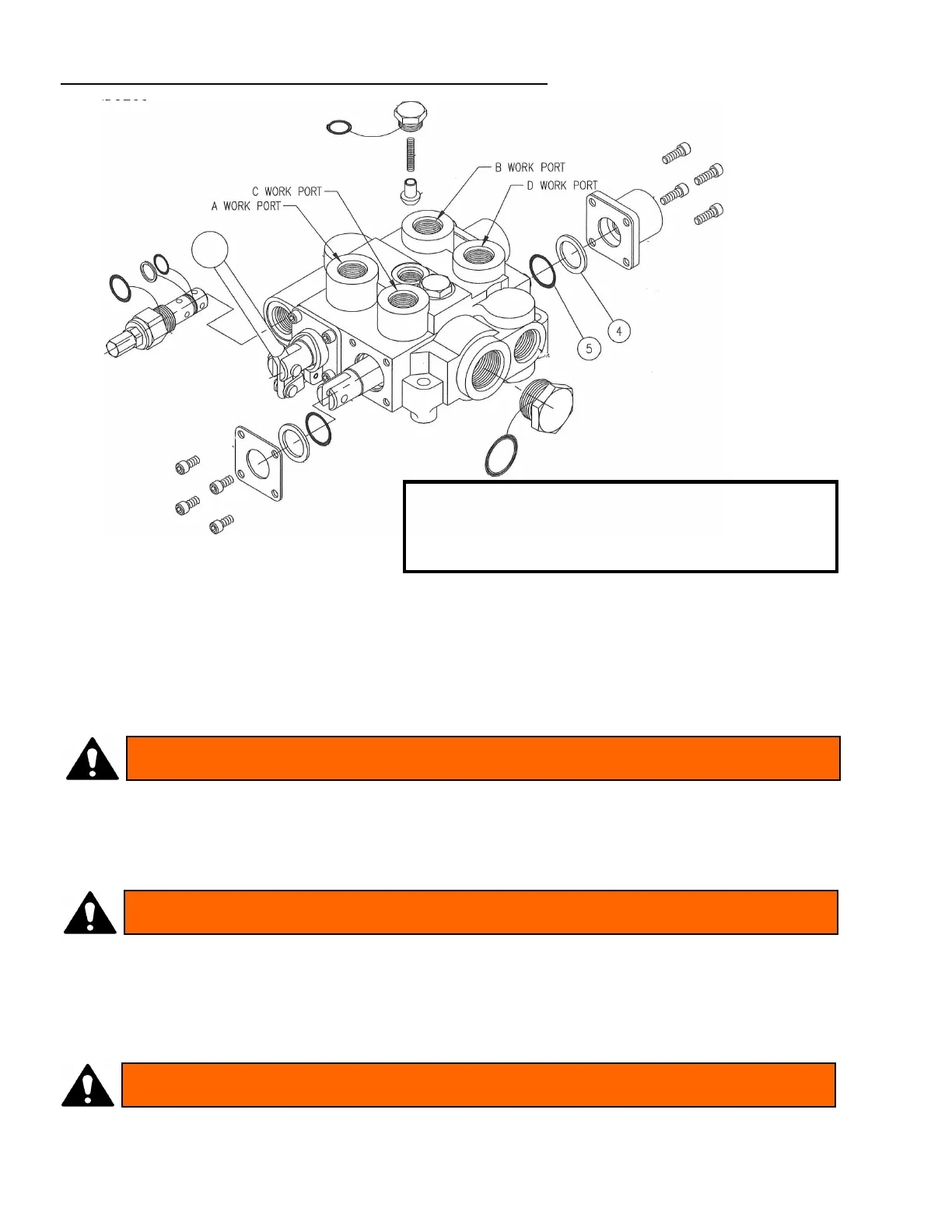

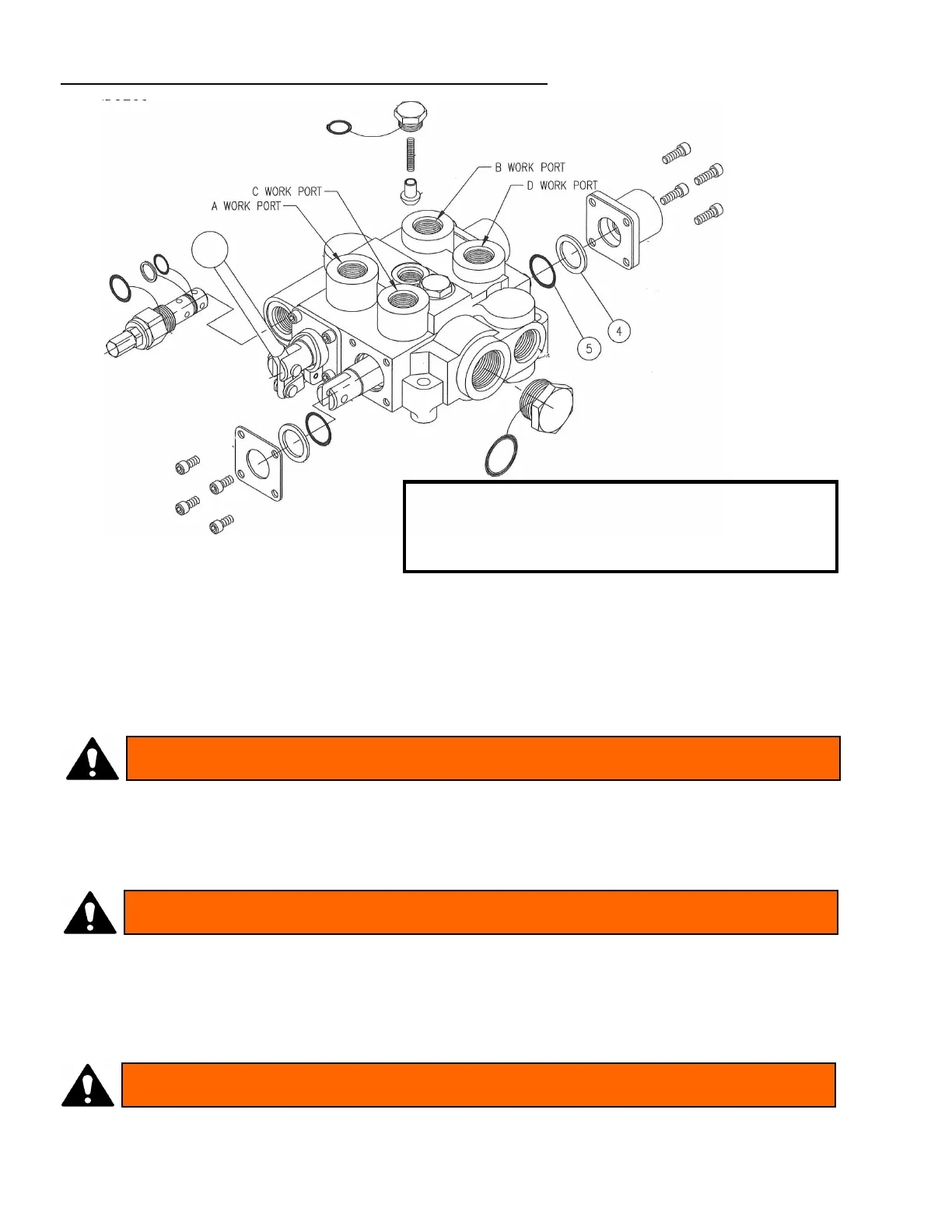

This diagram shows the locations of the seals that

can be replaced when necessary.

A Seal Kit (42-061-034) is available in repair parts

that contain all the seals shown.

Seal Replacement for Dual Spool Control Valve

1. All hydraulic valves must be properly installed into the hydraulic system to prevent

personal injury and/or property damage. Further the improper servicing of a valve may

result in personal injury and/or property damage. Please read and understand all catalog

and service information before starting. As with all mechanical work the proper tools,

knowledge, and safety equipment are required. Always wear safety glasses

2. Make sure all pressure has been relieved in the hydraulic lines before installing or

servicing a hydraulic valve.

Escaping hydraulic fluid under pressure can have sufficient force to penetrate skin,

causing serious personal injury. Do not use your hand to check for hydraulic leaks.

3. Before installing or servicing a hydraulic component make sure all weight has been re-

moved from the cylinders or motors before disconnecting hydraulic lines.

4. Do not exceed the operating specifications for pressure, flow or temperature. All hydraulic

systems require a means to limit the maximum pressure. This requires either a pressure

relief valve in the system or a pump that has pressure compensation.

Disconnecting the hydraulic lines while the Cylinder or Motor is under pressure may

result in the unexpected rapid movement of machine resulting in serious personal injury.

Overpressure may cause sudden and unexpected failure of a component in the hydraulic

system resulting in serious personal injury. Always use a gauge when adjusting a relief

valve.

WARNING

WARNING

WARNING

Loading...

Loading...