Section 9

High Pressure Water System

20412997

8-2012/Rev 12

9-2

9.2 System Options

The following system options are available at the time of purchase, or as upgrade kits for existing

equipment.

A redundant intensifier allows operation to continue if a problem is detected on the active

intensifier. Operation can be switched to the secondary intensifier until the next

convenient shutdown, when service can be performed on the primary intensifier.

A two liter attenuator is available for 30 and 50 horsepower models. Two liter attenuators

are standard on 60 and 100 horsepower models.

9.3 Operation

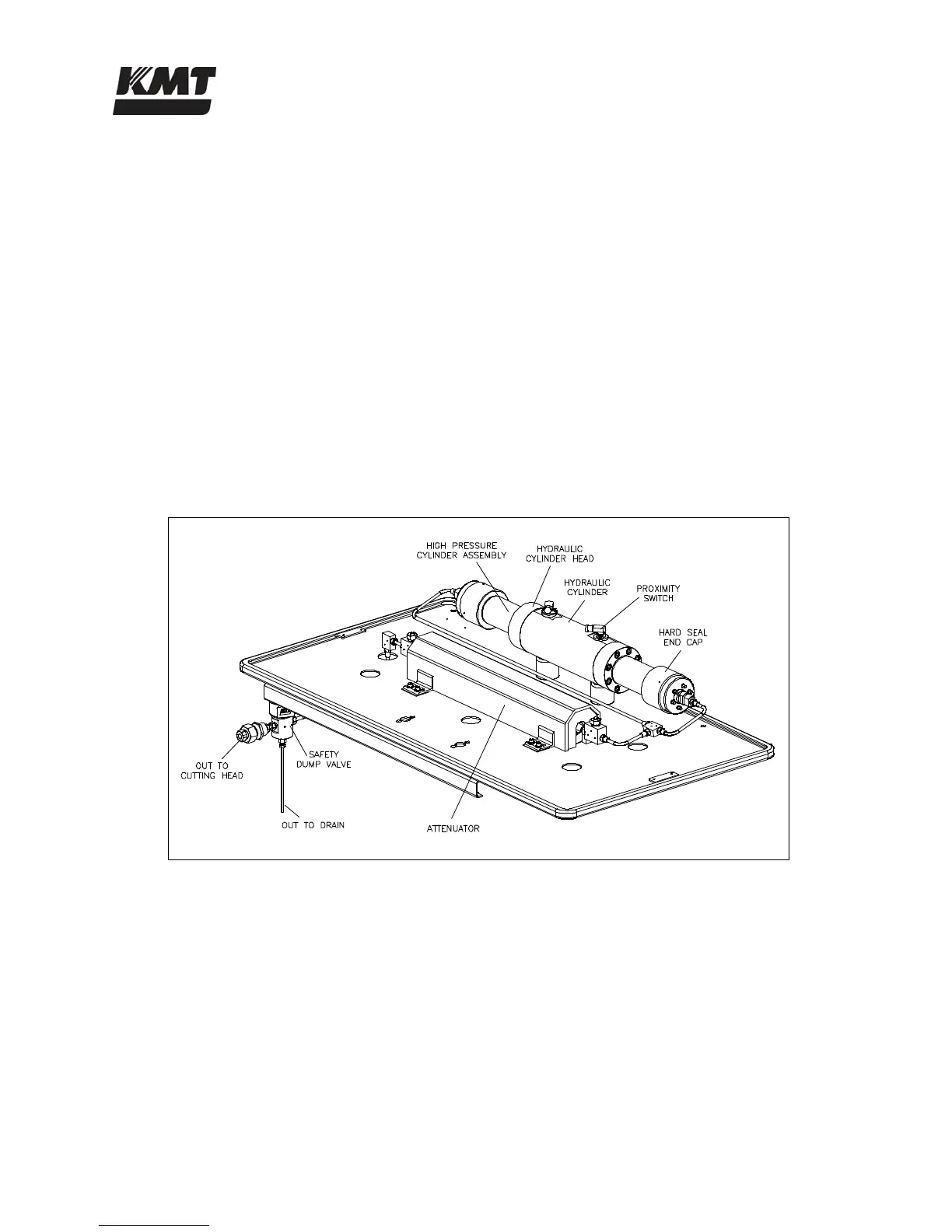

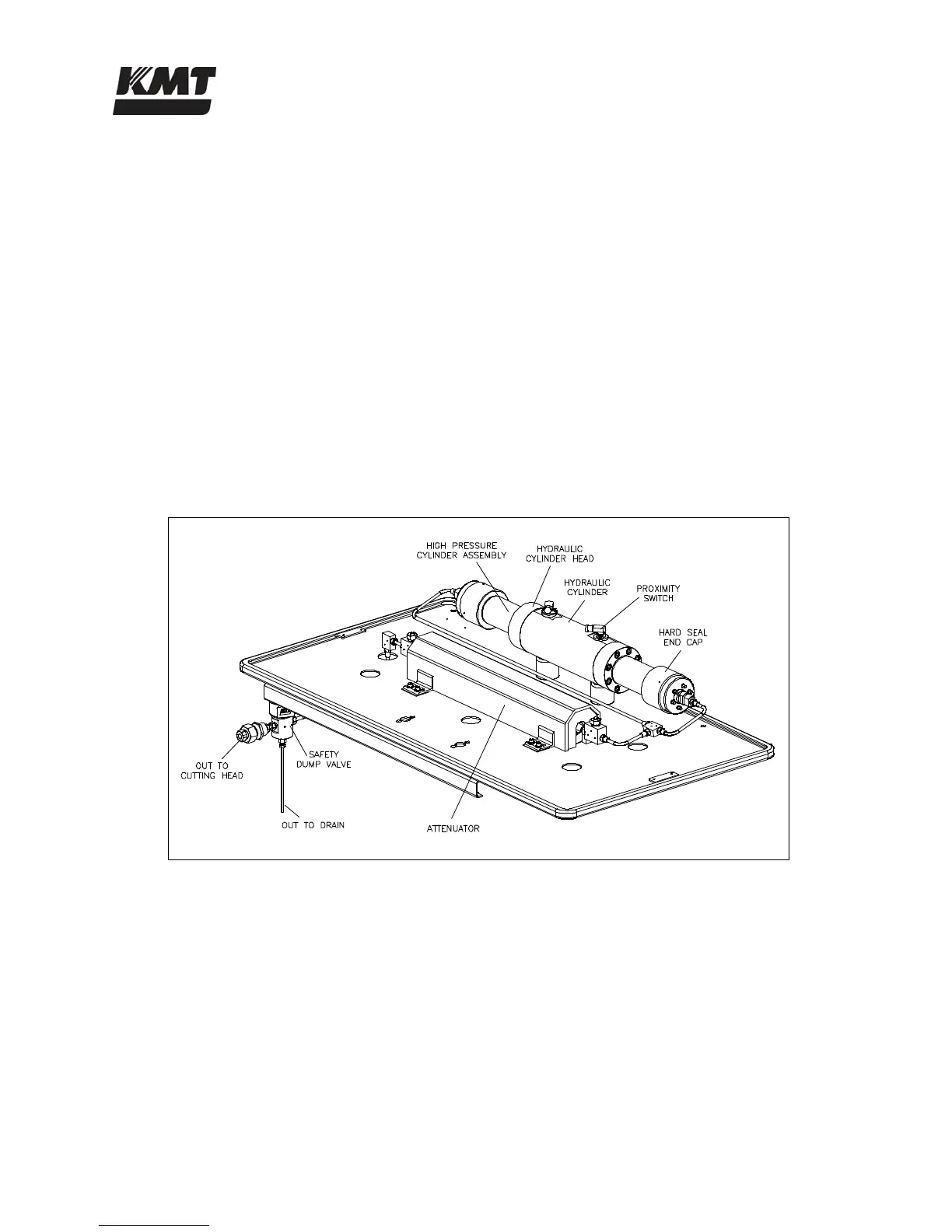

The directional control valve sends pressurized hydraulic oil to one side of the hydraulic cylinder.

The pressurized oil pushes against the piston, moving it in one direction until it activates the

proximity switch at the end of the stroke. The hydraulic flow is then sent to the opposite side of

the cylinder, and the piston reverses direction until it activates the proximity switch at the

opposite end of the stroke.

Figure 9-2: High Pressure Water System

The green light on the proximity switch indicates there is power to the switch. The red light

illuminates when the switch is activated. The proximity switches are magnetically activated by

the presence of the metallic surface of the piston. When the switch is activated, it sends a signal

to the PLC to change the flow of the directional control valve and reverse direction.

As the pressurized oil pushes the piston in one direction, the plunger on that end extends and

pushes against the water in the high pressure cylinder, increasing the pressure up to 60,000 psi

(4,137 bar). When the piston reverses direction, the plunger retracts and the plunger in the

opposite cylinder extends to deliver the high pressure water.

Loading...

Loading...