Section 7

Hydraulic System

20412971

8-2012/Rev 08

7-2

7.2 Optional System Components

Optional proportional pressure control enhances the standard high and low pressure selection by

allowing the operator to select or vary the hydraulic operating pressure from the control panel or

from a remote console. From the Pressure Control Screen the high pressure can be set as a

percentage, from 0% to 100%. An electronically controlled hydraulic cartridge valve receives a

signal from the PLC and automatically makes the operator selected adjustments.

As proportional pressure controls hydraulic oil pressure, it also determines cutting water pressure

based on the intensification ratio.

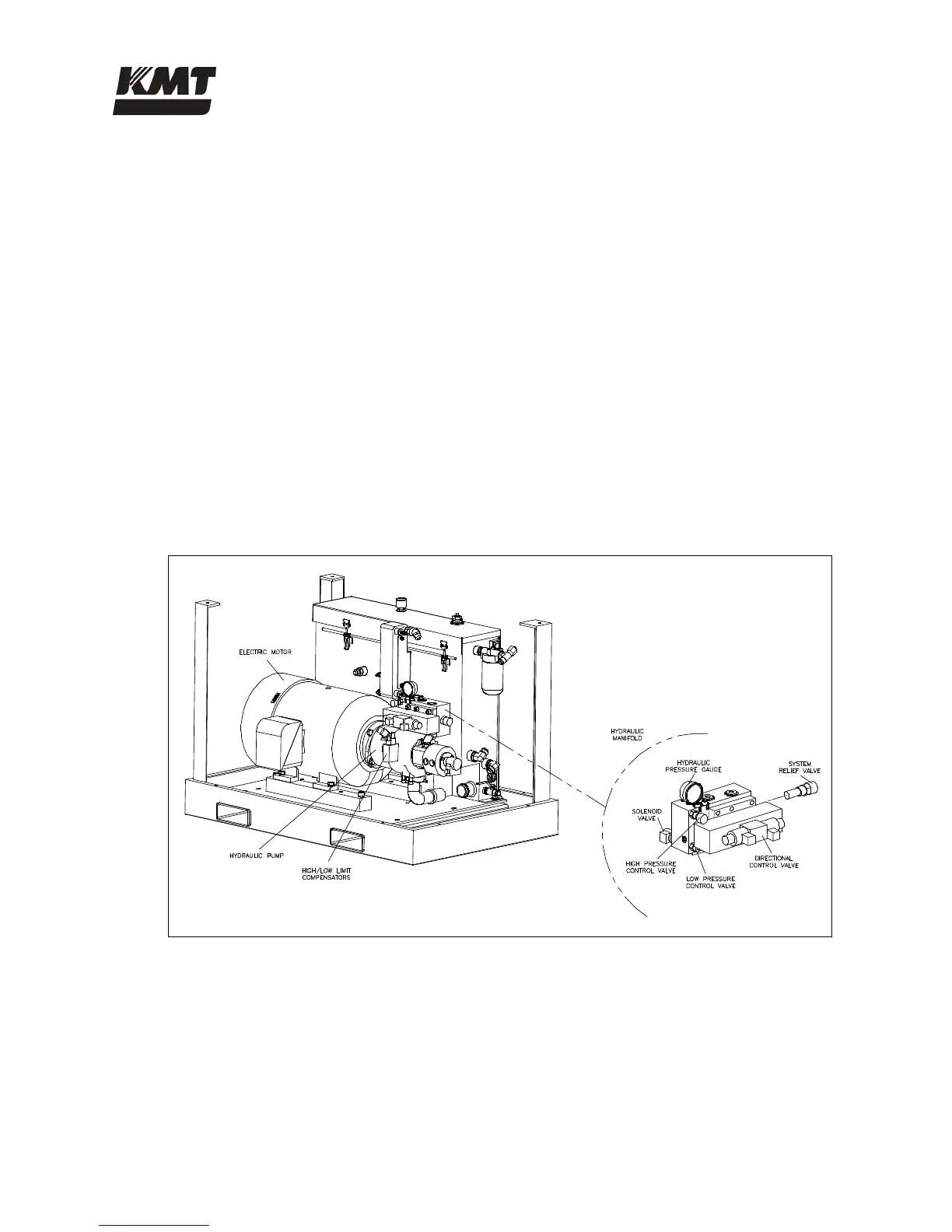

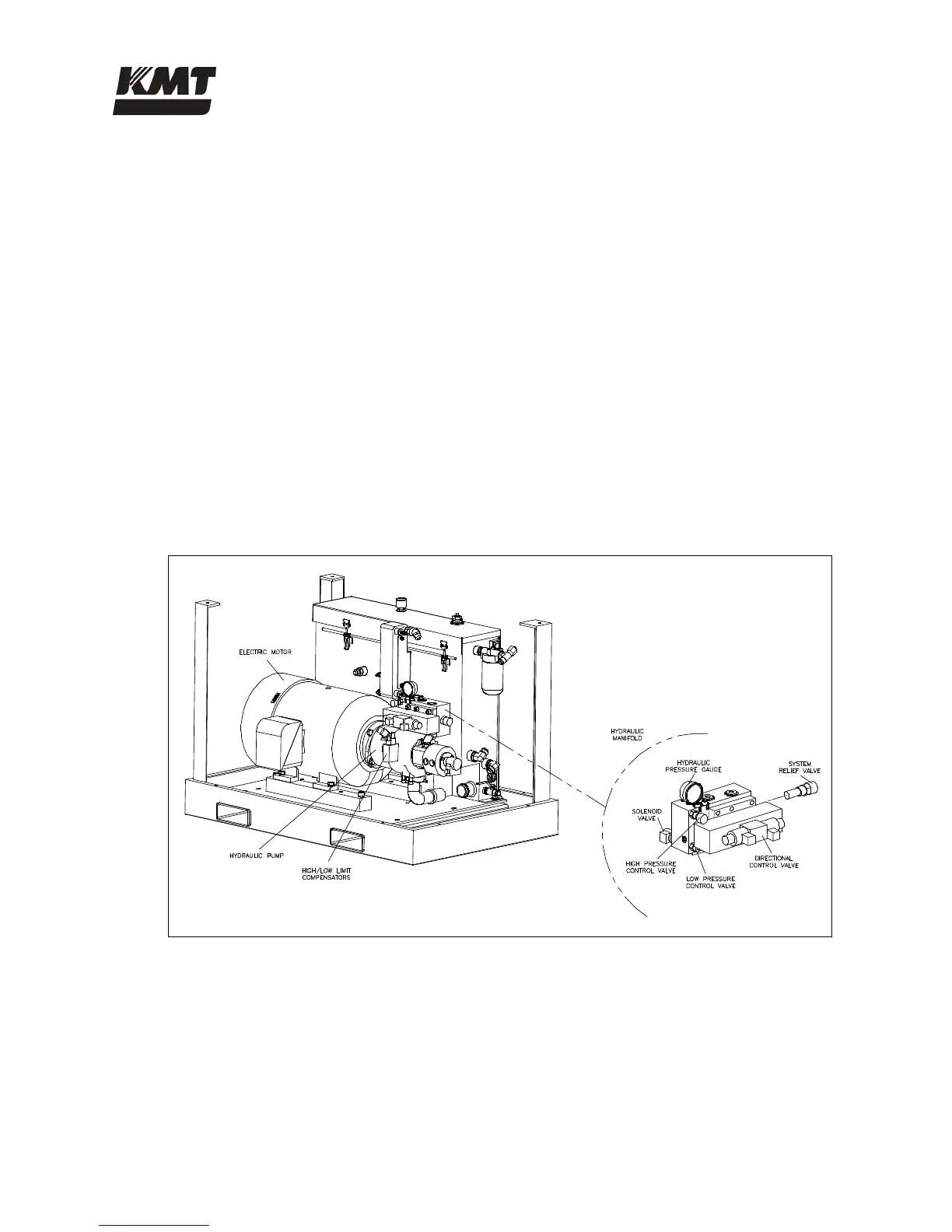

7.3 Operation

The electric motor drives three pumps mounted in tandem; the main hydraulic pump, the

recirculation pump and the booster pump. The motor drives the variable displacement, pressure

compensated hydraulic pump by means of a flexible coupling.

Hydraulic fluid from the reservoir is drawn into the inlet, low pressure side of the hydraulic

pump. Oil delivered to the pump should be maintained at 110-115 F (43-46 C). Hydraulic

fluid then enters the bottom of the manifold through an internal anti-rotation check valve. After a

shutdown, the anti-rotation check valve prevents the pump from running backwards.

Figure 7-2: Hydraulic System Components

The main system relief valve provides system protection by monitoring the oil pressure entering

the manifold. If the hydraulic pressure exceeds 3,400 psi (234 bar), the valve opens to limit the

pressure. The valve is factory calibrated and is not serviceable. A drain line from the valve

prevents oil from collecting behind the relief valve to ensure a constant pressure under all

operating conditions.

Loading...

Loading...