2.5 Requirements placed on materials

Basically, stud welding with tip ignition is possible with all materials suitable for arc welding. Even different mate-

rials, such as carbon steel and stainless steel, can be welded together by this method without any problems,

since blending between the two welding pools is only minimal, with hardly any brittle transition zones resulting.

Due to the extremely short welding time, a clean, smooth surface is vital for achieving good welding results.

The material combinations listed in chart 2 have been proven in practice. Since a precisely calibrated ignition tip

is an absolute necessity, standardized studs that comply with EN ISO 13918 should be used wherever possible.

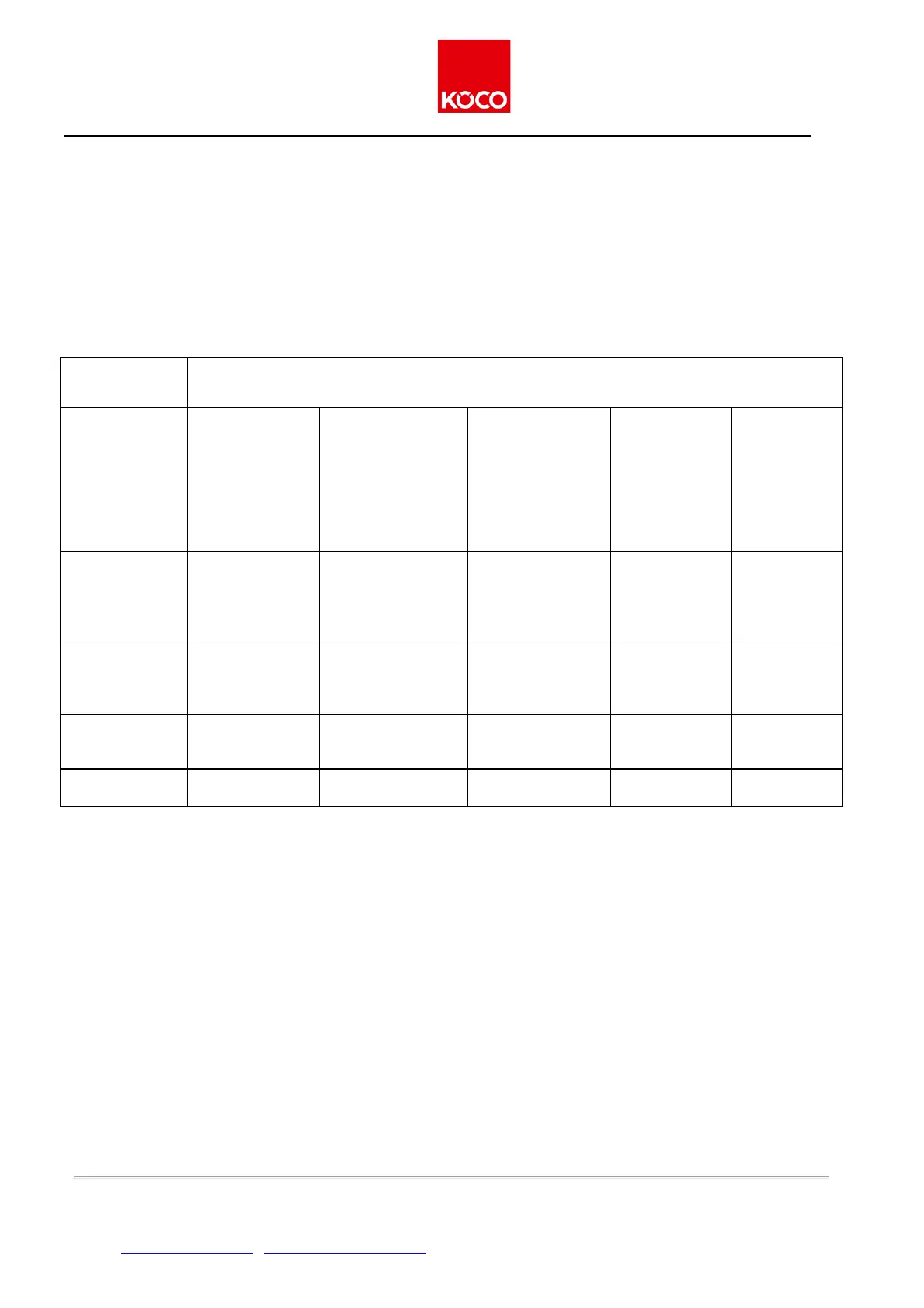

Chart 2: Material combinations for drawn-arc stud welding

non-alloy steel

up to app. 0.35%

C, for example

S235, S355, C35

stainless Austenite

steel, for example

1.4301, 1.4401,

1.4541, 1.4571

non-alloy steel up

to app. 0.35% C,

for example S235,

S355, C35, with

zinc or other metal

coating, max. 25

µm

copper and

copper alloys,

for example

CuZn37

(lead- free)

aluminium

and alu-

minium

alloys

non-alloy steel

up to 0.18%

C, for example

S235

suitable to a lim-

ited degree

suitable to a

limited degree

stainless aus-

tenite steel, for

example 1.4301

suitable to a lim-

ited degree

suitable to a lim-

ited degree

suitable to a lim-

ited degree

Issue 4/2019 ver. 2.0 page 12 of 42

Köster & Co. GmbH • D-58256 Ennepetal • Spreeler Weg 32 • Tel. +49 2333 8306-0 • Fax +49 2333 8306-38

Internet: http://www.koeco.net • E-Mail: koeco@koeco.net

Loading...

Loading...