3.8 Weld tests

Stud welds can be tested by several different methods:

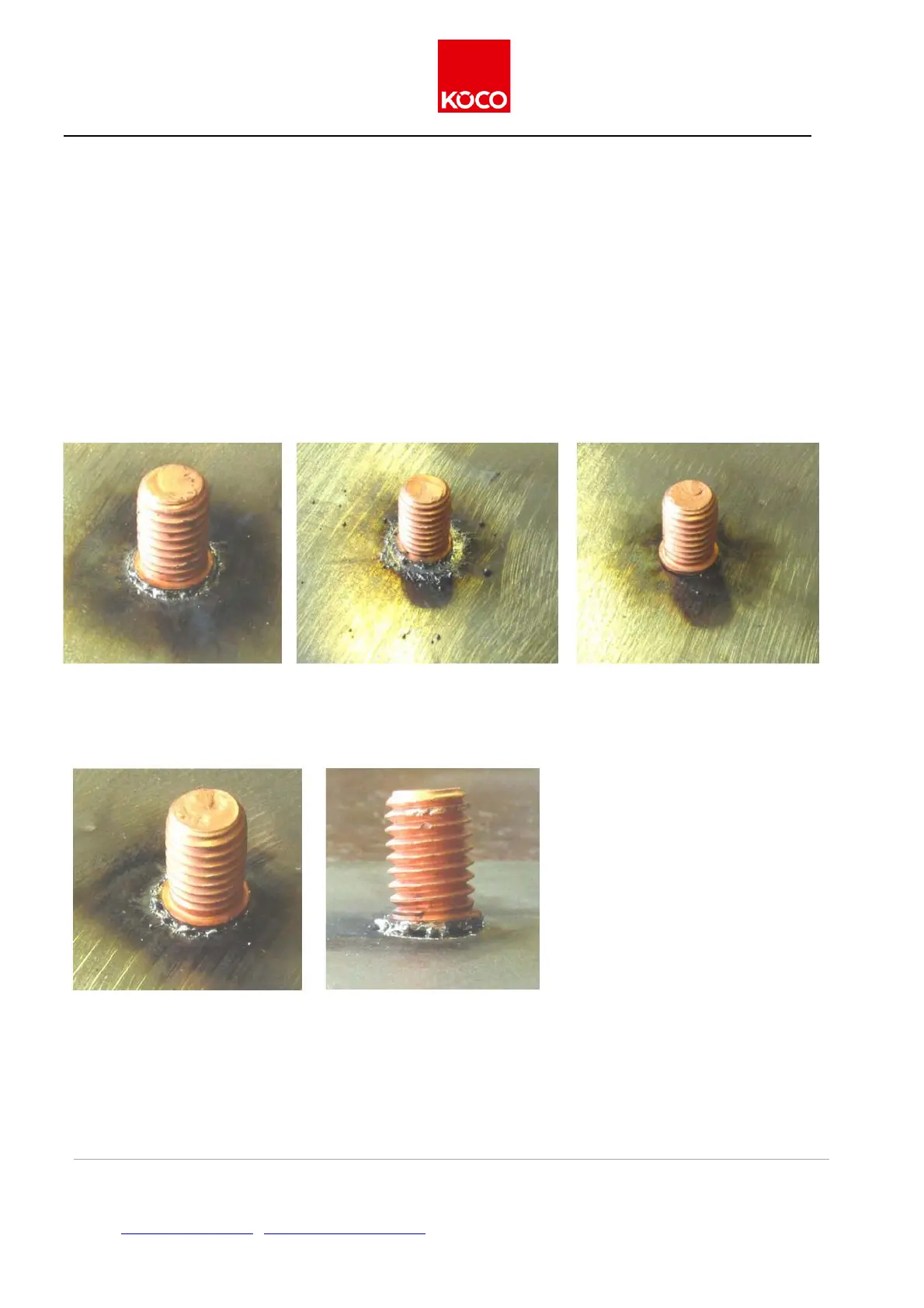

1. Visual inspection:

A good weld will be surrounded by a closed, even ring of splashes with a diameter exceeding the diameter of

the flange by no more than 1.5 mm.

There must not be any visible gap between the flange of the stud and the workpiece surface. It must be impos-

sible to squeeze even the edge of a sheet of paper between the flange and the workpiece.

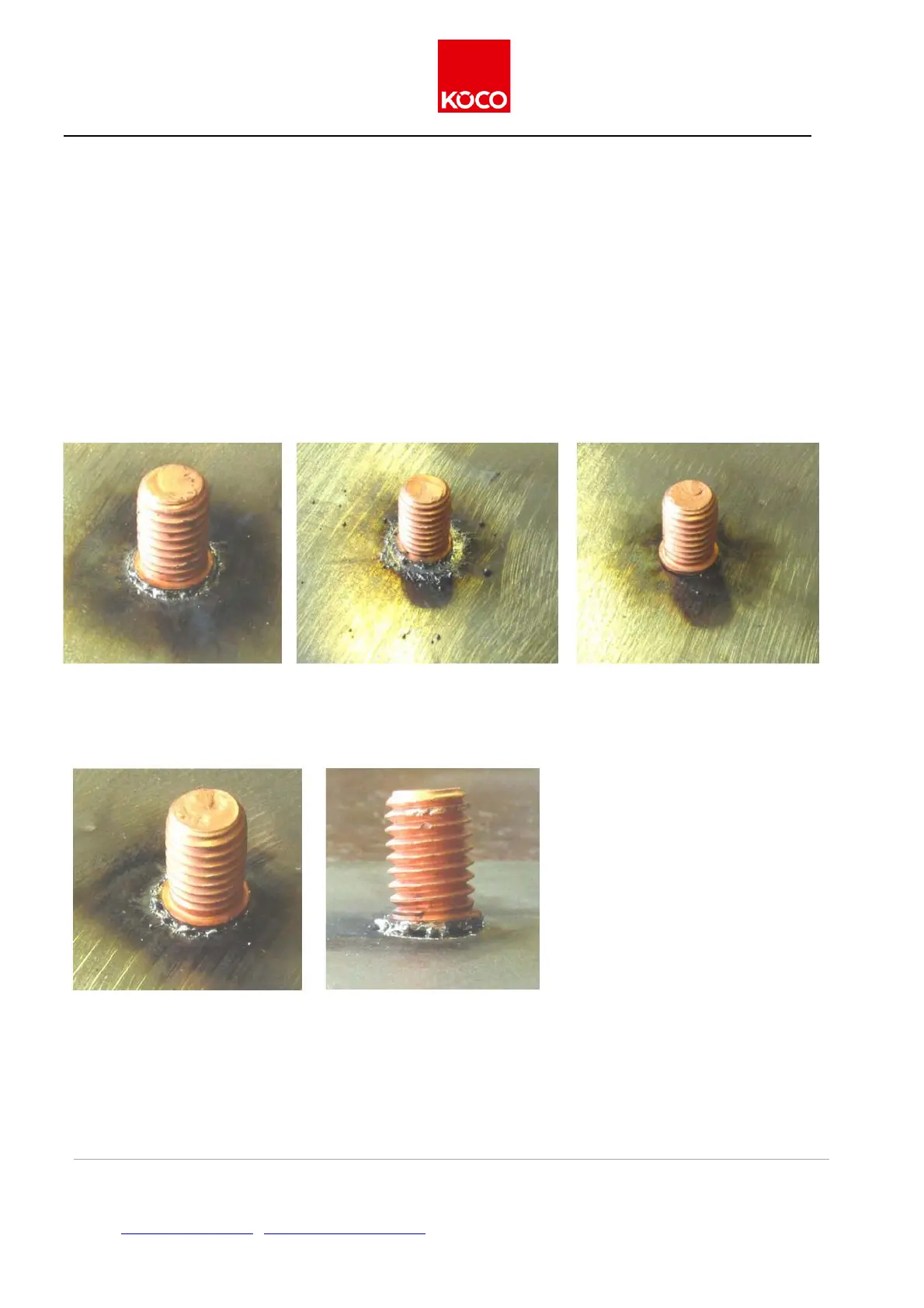

A frequent defect is the so-called plunge impediment. It happens whenever the plunging movement of the

stud is slowed, and consequently the plunge is delayed past the extinction of the arc and remains incomplete.

This kind of fault is sometimes hard to detect in the course of a visual inspection, therefore visual tests should

never be the only means of assessing a weld. Mechanical tests (bend test and tension test) should be carried

out as well.

Fig. 7: Weld with energy Fig.8: Energy set too high, there- Fig. 9: Weld with energy set too

supply correctly set and an fore ring of splashes too wide low, consequently no visible

even ring of splashes ring of splashes present

Fig. 10: One-sided ring of

splashes, caused by arc

blowing

Fig. 11: Defective weld

caused by a plunging im-

pediment. A gap is visible

between the stud and the

workpiece.

Issue 4/2019 ver. 2.0 page 18 of 42

Köster & Co. GmbH • D-58256 Ennepetal • Spreeler Weg 32 • Tel. +49 2333 8306-0 • Fax +49 2333 8306-38

Internet: http://www.koeco.net • E-Mail: koeco@koeco.net

Loading...

Loading...