2 Stud Welding with Tip Ignition

Stud welding with tip ignition is a process for welding mostly cylindrical metallic parts with diameters from about

0.8 to 10 mm onto metallic workpieces from approximately 0.6 mm thickness. This process requires a capacitor

plus a mobile device (welding gun).

Prior to welding, the stud is placed above the workpiece (fig.1 - 1). When the gun is triggered and the welding

thyristor ignites, the piston of the gun moves the stud towards the workpiece. As soon as the ignition tip of the

stud makes contact, a strong current builds up quickly, which causes explosive melting and partial evaporation

of the ignition tip. (fig. 1-2). The arc generated by this process melts the tip of the stud and a portion of the

workpiece. During welding time, the stud continues its steady movement towards the workpiece until it comes to

a halt in the welding pool. (fig. 1 - 3). Then the drawn arc is extinguished by a short-circuit, and the welding pool

solidifies (fig. 1 - 4).

Due to the high speed of the stud’s movement, the impact made by its plunge causes part of the welding pool to

splash out, forming a circle of splashes which can be used as an indicator for assessing the weld. (see chapter

3.7).

Welding time is approximately 1 to 3 milliseconds. Due to the extremely short welding time, burning in is limited

to about 0.2 mm; consequently, impairment to the rear surface of the workpiece is minimized.

The length of the ignition tip is the decisive factor determining the length of the welding time, with all other condi-

tions being equal. Therefore, studs with deformed ignition tips must not be used. Nor should centre punch marks

be used to mark the position of the stud on the workpiece, since welding time will be shortened by the ignition tip

plunging into a recess.

More details are available from the DVS-Technical bulletins 0903 and 0904.

Depending on the layout of the gun and its welding time range, a distinction is made between gap welding and

contact welding. The difference is that, in the first case, welding takes place across a gap of air of pre-

determined width G. In the second case, the stud is in direct electrical contact with the workpiece which means

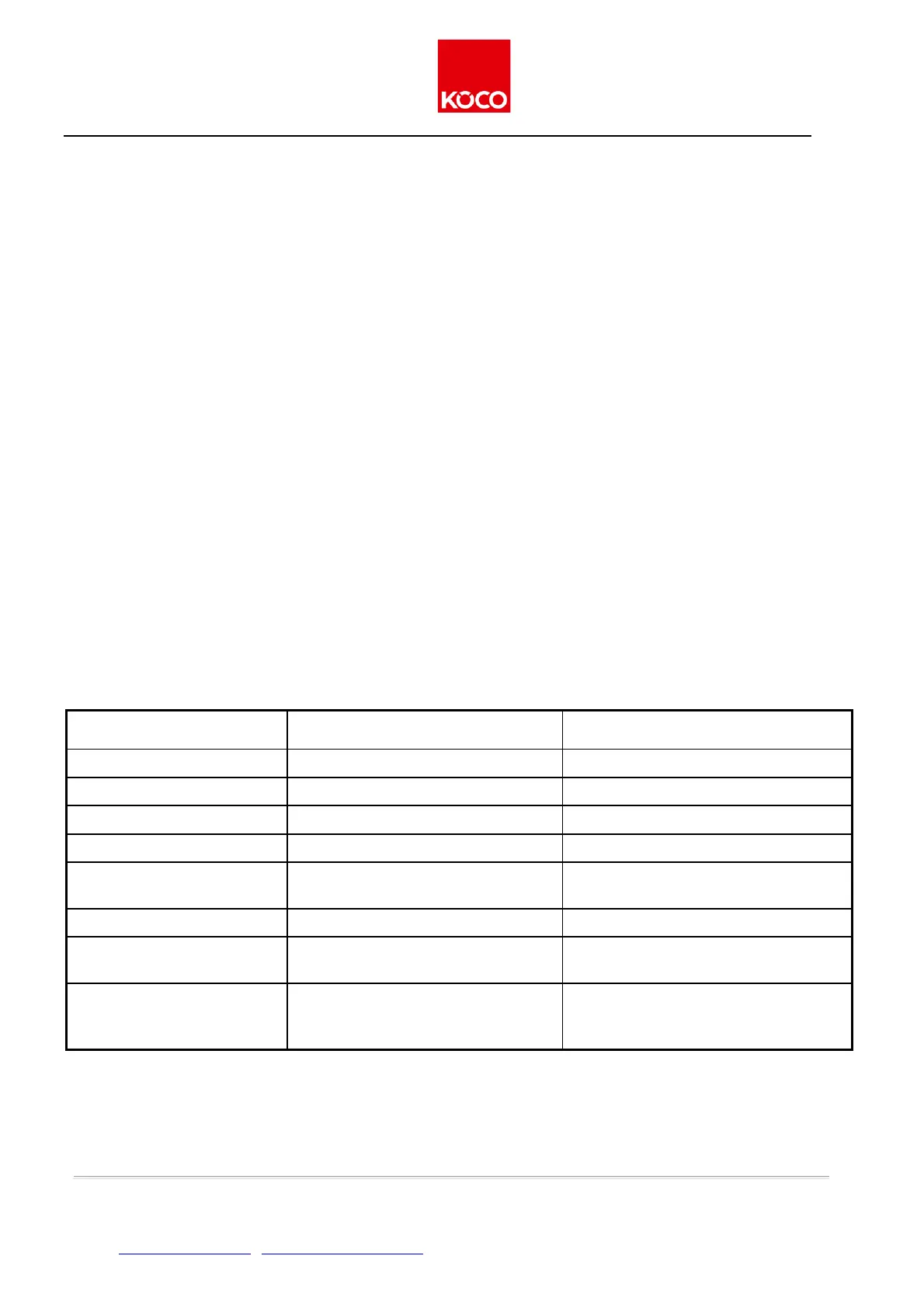

G = 0. Chart 1 illustrates the characteristics and recommended fields of application for both processes.

Chart 1: Characteristics and applications of tip ignition stud welding

Gap welding (gun ESP 1 S)

contact welding (gun ESP 1 K)

0.8 to 10 (aluminium up to 6)

0,8 to 10 (aluminium not recommended)

80 to 120, depending on piston

dimen-sions

0,5 to 1, aluminium 1 to 1,5

mostly on time, premature ignition

possible

automatic welding, aluminium, brass

manual welding of steel (non-alloy

and alloyed), galvanized, zinc-coated

or oiled surfaces

Issue 4/2019 ver. 2.0 page 8 of 42

Köster & Co. GmbH • D-58256 Ennepetal • Spreeler Weg 32 • Tel. +49 2333 8306-0 • Fax +49 2333 8306-38

Internet: http://www.koeco.net • E-Mail: koeco@koeco.net

Loading...

Loading...