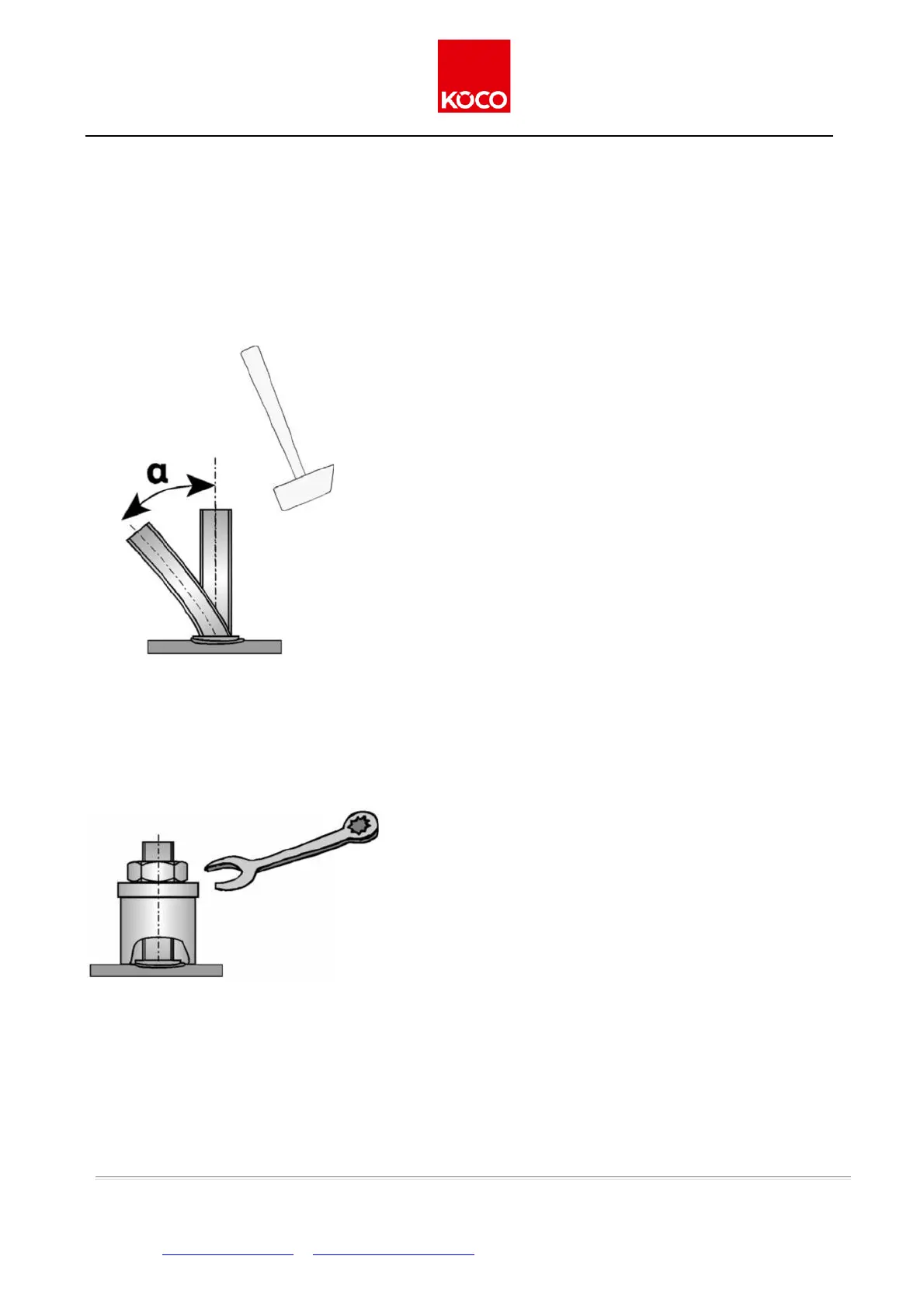

2. Bend Test:

A good weld must reach a bending angle of 30° without developing cracks in the welding zone. The bend test

serves to check the selected settings as well as the suitability of the welding conditions and the combination of

materials. For short, thick studs, which cannot be bent as described above, for example M 8 x 12, the stability

of the weld must be checked by another method. Basically, the weld zone should always be more stress-

resistant than either the stud or the workpiece. In any case, the responsibility always rests with the processor,

depending on the application and the risks or danger involved in a possible failure of the welding connection.

Bending the stud with a hammer or a lev-

erage tube by c. = 30°. The weld has

passed the test if the weld zone or the

heat affected zone shows no cracks or

fissures following bending.

Fig. 12: Bend test of a stud welding connection

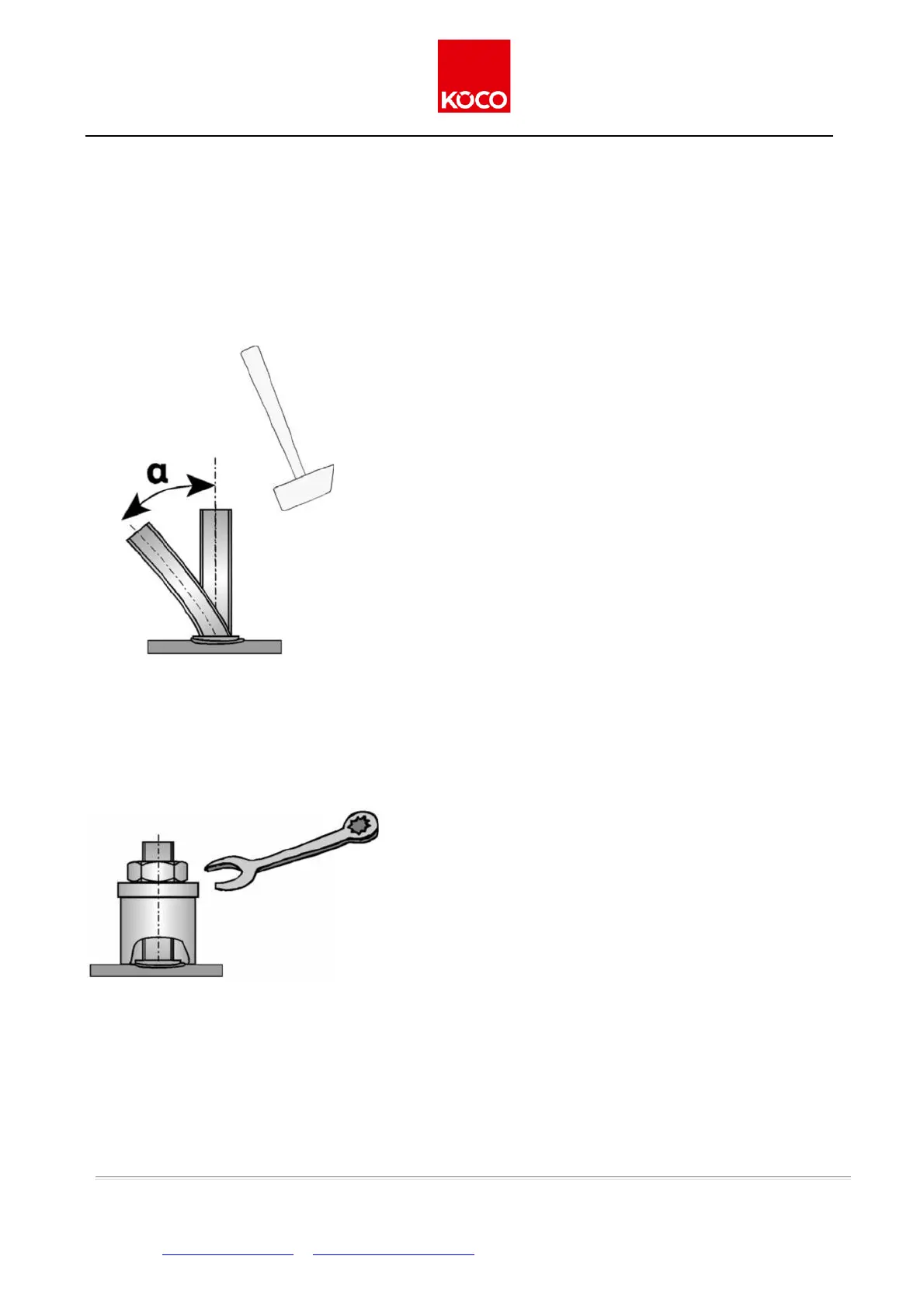

3. Tension test:

Threaded studs can be mounted on a fixed support and then tested with a gripping nut. The test can be either

non-destructive, i.e. the nut is tightened up to a certain torque (for actual values see DVS-Technical bulletin

0904), or it can be destructive, i.e. the nut is tightened up to the breakage point. Breakage should always occur

outside the weld zone. If breakage occurs in the weld zone, the nominal breakage-resistance value of the stud

material should at least have been reached before the connection breaks.

Fig. 13: Tensile test of a stud welding connection

3.9 Maintenance of the Power Source

The mains plug must be disconnected prior to any servicing. The housing must not be opened unless the

ma-

chine is voltage-free. Especially when working in dusty surroundings, dust

will collect on parts of the machine. It can impair the

per-

formance of the appliance’s cooling system, with a consequent risk of overheating. Moreover, it reduces the

resistance of insulating materials, and, combined with moisture, it can cause malfunctions in the control system

Therefore open the housing at regular intervals to blow out the dust. This is vital in the case of metallic dust,

Issue 4/2019 ver. 2.0 page 19 of 42

Köster & Co. GmbH • D-58256 Ennepetal • Spreeler Weg 32 • Tel. +49 2333 8306-0 • Fax +49 2333 8306-

38 Internet: http://www.koeco.net • E-Mail: koeco@koeco.net

Loading...

Loading...