As a matter of principle a higher spring force (ESP 1 K) and a larger gap (ESP 1 S) reduce welding time. With a

minimum spring force, respectively a minimum gap (long welding time) the capacitor can already be discharged

before the stud reaches the workpiece ("cold plunge"). When subjected to a load the stud will break off without

any plastic deformation; spots of bright metal will appear on the fracture surface.

Our experience has shown that spring forces under +1 and gaps under -4 are generally not recommendable.

With a maximum spring force, respectively maximum gap, if there is insufficient voltage the welding time can be

shortened so much that the arc no longer covers the entire area of the stud. Here, when subjected to a load the

studs would also break off without great plastic deformation, and the fracture area would show incomplete melt-

ing.

A longer welding time (reduction of the spring force, respectively reduction of the gap) can improve the quality of

the welding on slightly soiled (oily) surfaces.

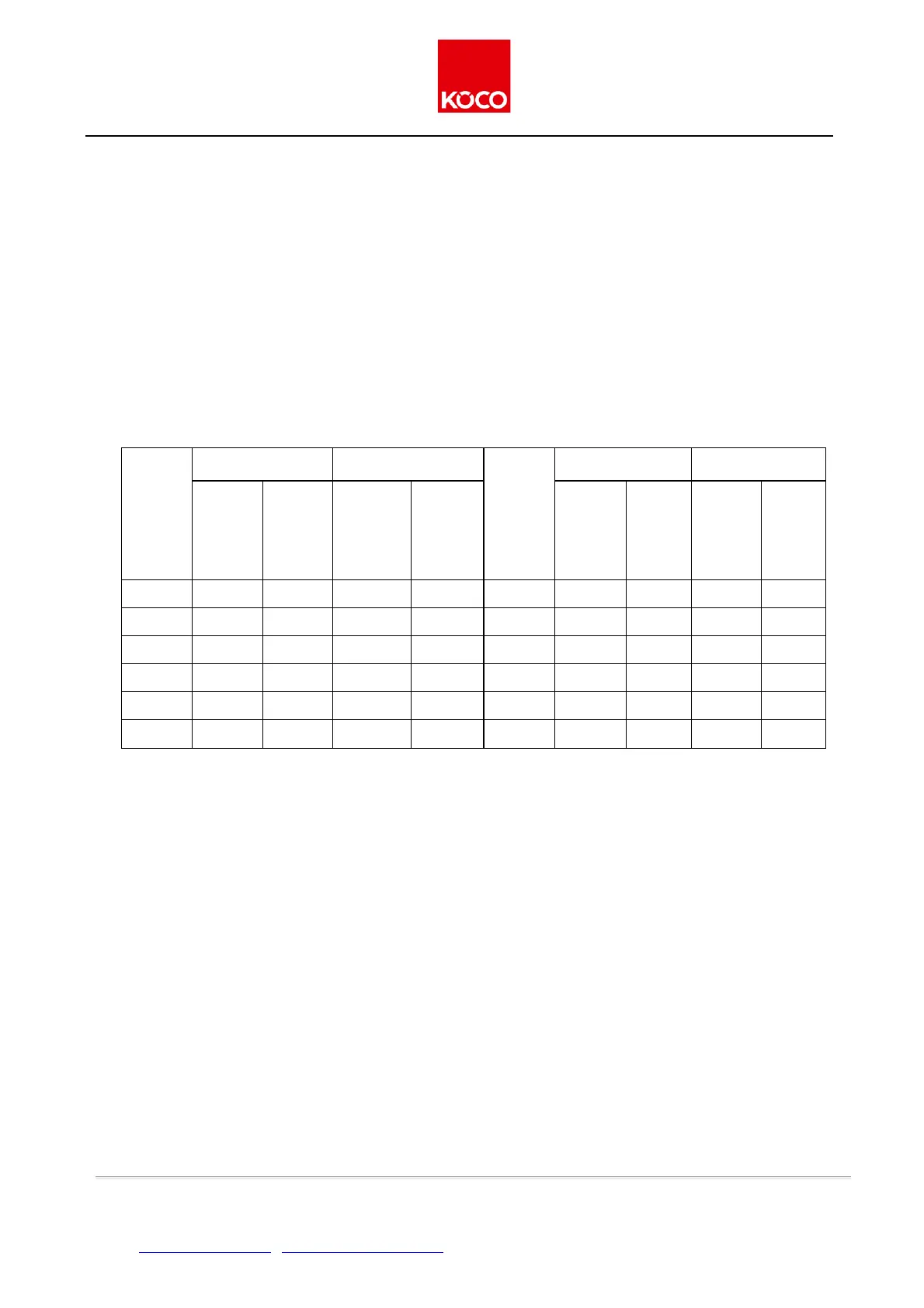

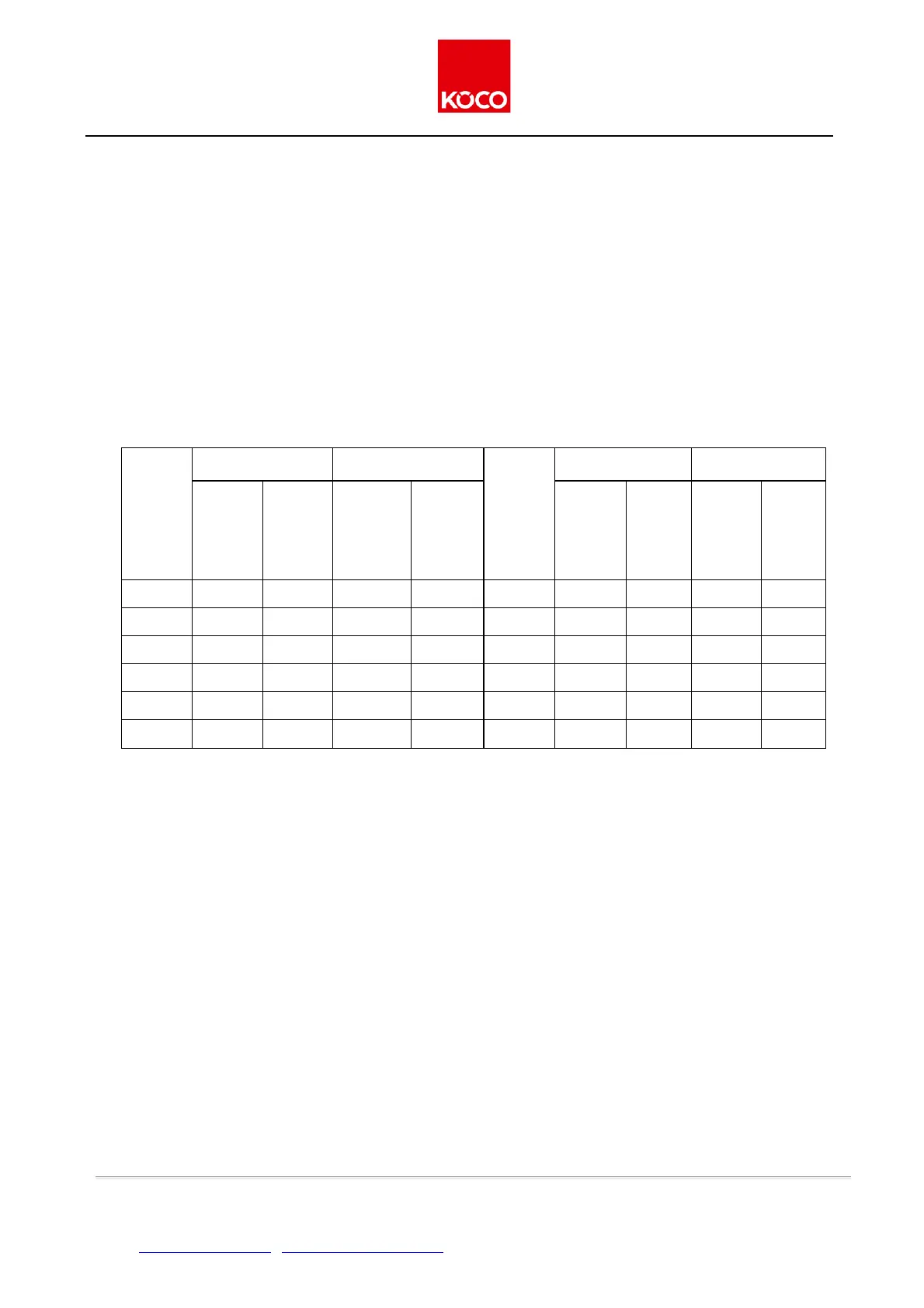

The following recommended values for charging voltage and spring force, respectively gap, can serve

as a guide:

Steel,

non-

alloy

steel,

brass

Steel,

non-alloy

steel,

brass

Steel,

non-

alloy

steel,

brass

Steel,

non-

alloy

steel,

brass

Please note: for M 8 aluminium studs and M 10 steel studs, satisfactory results can only be achieved under

particularly favourable conditions, such as clean surfaces, thin sheet metal, faultless ignition tips, firm support,

symmetrical ground connection, etc. The sole responsibility for applicability rests with the user.)

3.7 The Welding Process

1. Place the prepared welding gun on the workpiece with all its legs firmly seated. This causes the piston of

the gun to be pushed back by the length of the protrusion, and simultaneous tightening of the pressure

spring. It is recommended to stabilize the gun from the rear by holding it down with the free hand, to

prevent it from moving during the welding process.

The chuck must not come into contact with the workpiece except through the stud.

It is vital that the piston movement is not obstructed in any way.

Ensure that the workpiece is firmly supported; it should under no circumstances rebound when the pistol is

applied!

2. Trigger the gun and keep it still until the welding pool has cooled.

3. Lift off the gun from the welded stud, keeping it straight in the axial direction of the stud. If the gun is not

lifted off straight, the gripping jaws of the chuck may be bent open, which prevents a sufficiently tight grip

on the next stud.

4. Now check the weld (by visual inspection and possibly other tests according to EN ISO 14555) and adjust

settings if necessary. Test welds should always be carried out before starting a series of welds.

Issue 4/2019 ver. 2.0 page 17 of 42

Köster & Co. GmbH • D-58256 Ennepetal • Spreeler Weg 32 • Tel. +49 2333 8306-0 • Fax +49 2333 8306-38

Internet: http://www.koeco.net • E-Mail: koeco@koeco.net

Loading...

Loading...