Reassembly

56 62 690 02 Rev. DKohlerEngines.com

NOTE: Make sure engine is assembled using all

specifi ed torque values, torque sequences, and

clearances. Failure to observe specifi cations

could cause severe engine wear or damage.

Always use new gaskets. Apply a small amount

of oil to threads of critical fasteners before

assembly, unless a sealant or Loctite

®

is

specifi ed or preapplied.

Make sure all traces of any cleaner are removed before

engine is assembled and placed into operation. Even

small amounts of these cleaners can quickly break down

lubricating properties of engine oil.

Check oil pan, crankcase, cylinder heads, and valve

covers to be certain all old gasket material has been

removed. Use gasket remover, lacquer thinner, or paint

remover to remove any remaining traces. Clean surfaces

with isopropyl alcohol, acetone, lacquer thinner, or

electrical contact cleaner.

Install Flywheel End Oil Seal

1. Make sure seal bore of crankcase is clean and free

of any nicks or burrs.

2. Apply a light coat of clean engine oil to outside

diameter of oil seal.

3. Install oil seal into crankcase using a seal driver.

Make sure oil seal is installed straight and true in

bore and tool bottoms against crankcase.

Install Lifter Feed Chamber Gaskets and Cover

1. Install lifter feed chamber gasket, followed by lifter

feed cover over lifter feed chamber.

2. Install screws. Make sure all parts are properly

aligned. Torque screws to 6.2 N·m (55 in. lb.) into

new holes, or 4.0 N·m (35 in. lb.) into used holes.

Install Crankshaft Bearing (fl ywheel)

If bearing was removed in servicing, install a new

bearing using an arbor press and driver.

1. Make sure crankcase bore for bearing is clean, dry

and free of nicks or burrs.

2. Press fl ywheel side main bearing in place with notch

oriented in 12 o’clock position using an arbor press

and driver. Make sure bearing is fully seated against

fl ange and oil feed hole is open in crankcase.

3. Apply a light coat of clean engine oil to inner surface

of main bearing.

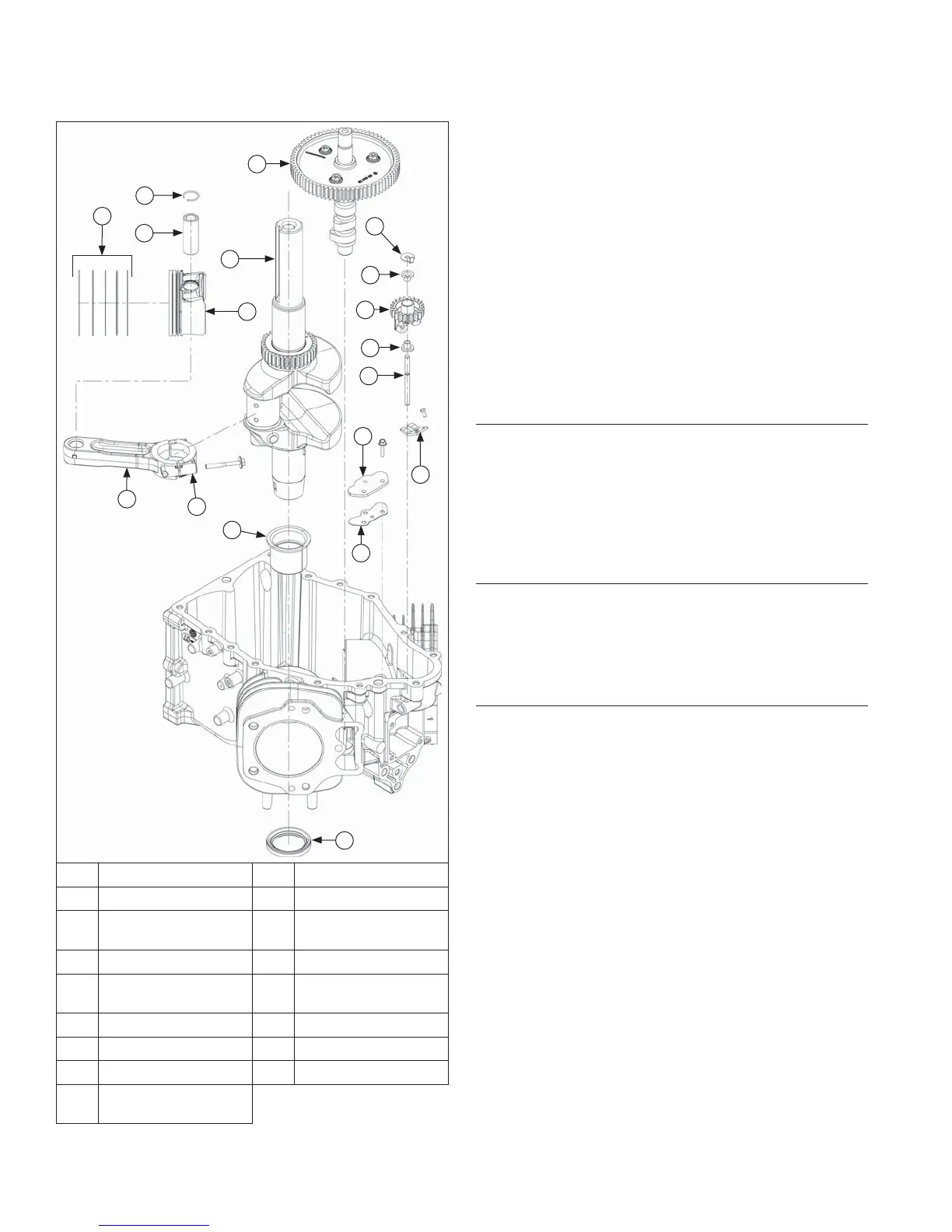

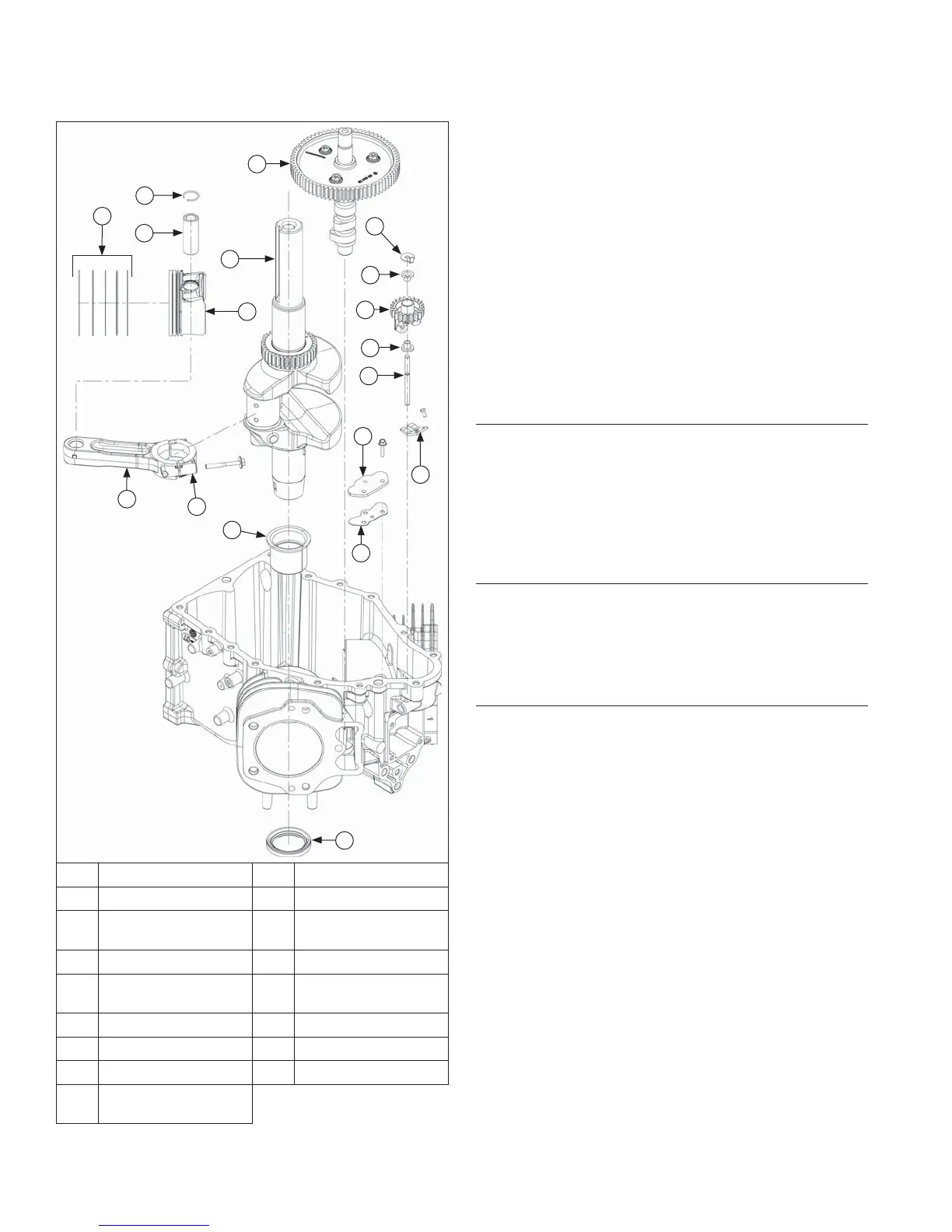

Crankcase Components

A

Q

O

B

C

P

D

E

I

J

K

L

M

N

C

F

G

H

A Camshaft B Locking Tab

C Regulating Pin D Governor Gear

E Cross Shaft F Lifter Feed Cover

Gasket

G Lifter Feed Cover H Governor Yoke

I Crankshaft J Connecting Rod

End Cap

K Connecting Rod L Piston Pin

M Piston Pin Retainer N Piston

O Piston Ring Set P Oil Seal

Q Crankshaft Bearing

(Flywheel)

Loading...

Loading...