Reassembly

62 62 690 02 Rev. DKohlerEngines.com

c. Hold adjuster nut in this position and tighten

locking setscrew. Torque setscrew to 7.3 N·m (65

in. lb.).

d. Repeat procedure for other valve on this side.

4. Viewed from PTO end, rotate crankshaft 270° (3/4

turn) counterclockwise and align crankshaft keyway

with cylinder 2, which now puts that cylinder at TDC

on compression stroke.

5. Repeat steps 3-5 for setting valve clearance on

cylinder 2.

6. Rotate crankshaft to check for free operation of

valve train. Check for clearance between valve

spring coils at full lift, or bending of push rod(s) can

occur. Minimum allowable clearance is 0.25 mm

(0.010 in.).

Check Assembly

Rotate crankshaft a minimum of two revolutions to check

assembly and overall proper operation.

Check if engine can be turned over completely and

compression is noted. If it cannot (locks up at some

point), return piston to TDC between intake and exhaust

strokes fi rst for one cylinder and then other waiting ten

minutes to allow lifters to bleed down, then check for

compression again.

Install Valve Covers

1. Make sure sealing surfaces are clean and free of

any nicks or burrs.

2. Install and properly seat seal onto each valve cover.

3. Install valve covers on same side as they were

originally installed.

4. Install a new grommet on each valve cover mounting

screw. Start each screw into hole.

5. Check position of each cover and seal, then torque

screws to 13.6 N·m (120 in. lb.).

Install Spark Plugs

1. Check gap using wire feeler gauge. Adjust gap to

0.76 mm (0.030 in.).

2. Install plug into cylinder head.

3. Torque plug to 27 N·m (20 ft. lb.).

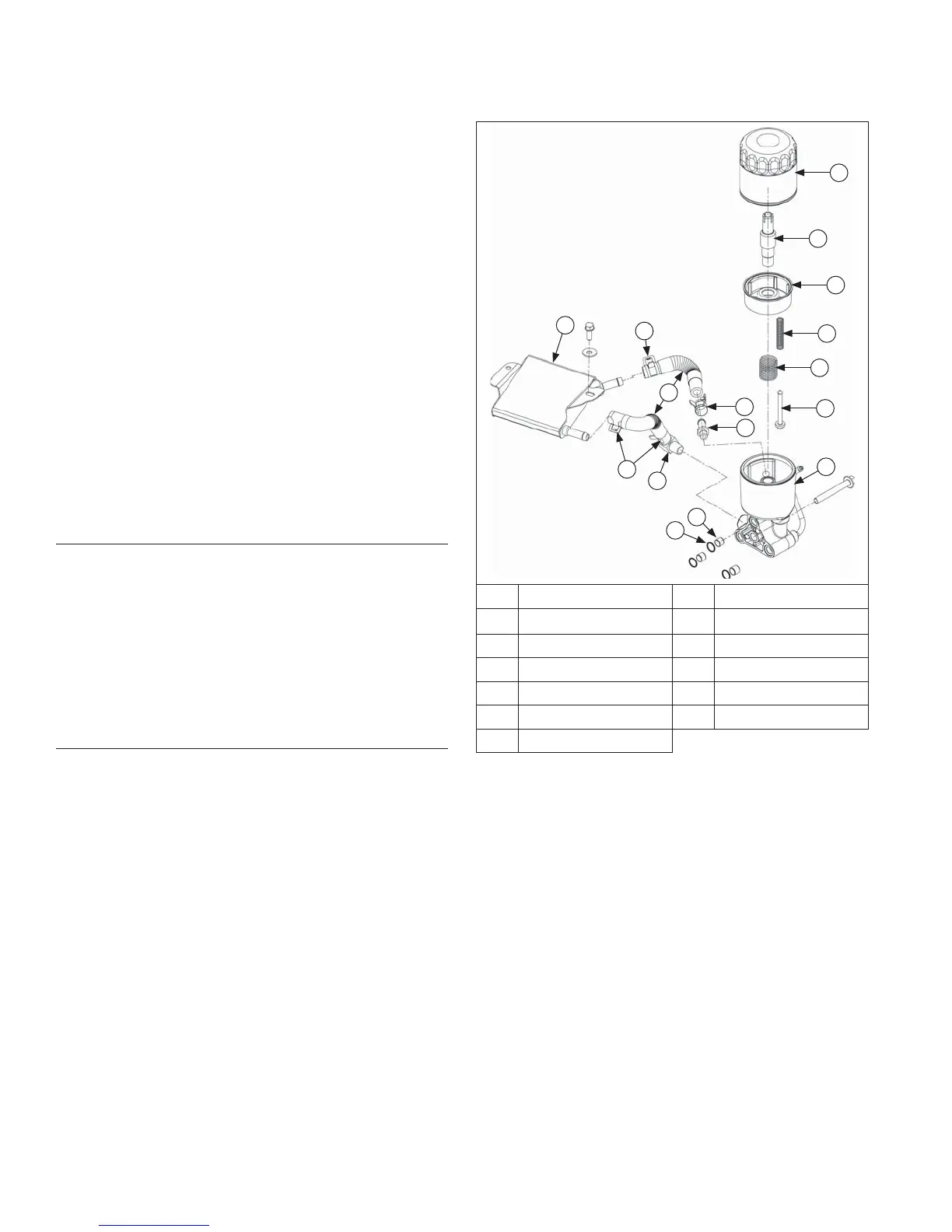

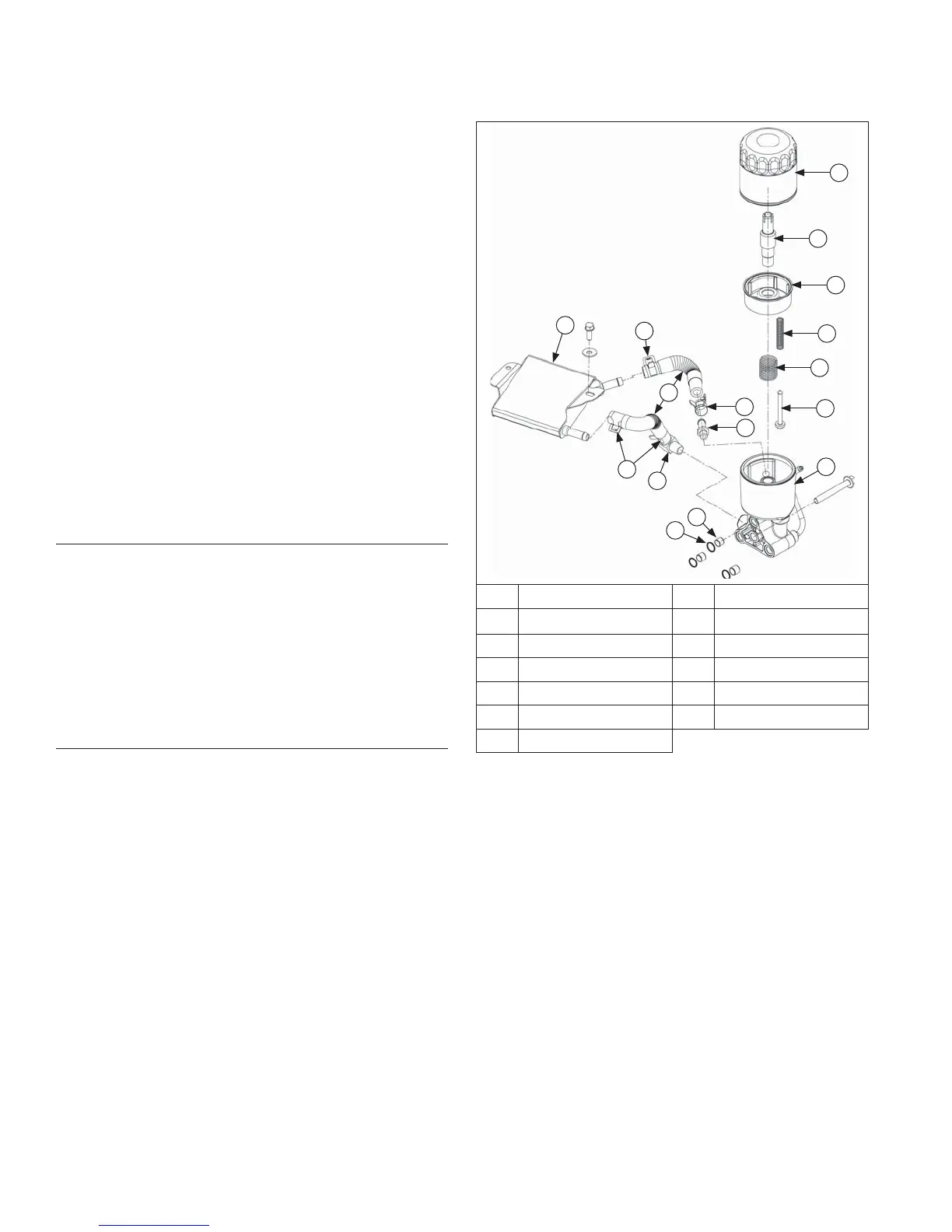

Oil Cooler/Filter Components

A

B

C

D

E

F

G

H

L

K

M

J

K

J

K

I

A Oil Filter B Oil Filter Nipple

C Cup D Valve Spring

E Cup Spring F Oil Filter Valve

G Oil Filter Housing H Pin

I O-Ring J Fitting

K Hose Clamp L Hose

M Oil Cooler

Loading...

Loading...