Reassembly

66 62 690 02 Rev. DKohlerEngines.com

2. Align oil cooler with bosses in backing shroud

assembly. Secure screws and washers to 2.2 N·m

(20 in. lb.).

Install Cooling Fan and Debris Screen

CAUTION

Failure to utilize or reassemble debris screen

as designed could result in debris screen

failure and serious personal injury.

1. Position cooling fan onto fl ywheel aligning mounting

locations. Apply a small amount of Loctite

®

243™

Threadlocker to threads and install long mounting

screws. Torque screws to 9.9 N·m (88 in. lb.).

2. Apply a small amount of Loctite

®

243™ Threadlocker

to external threaded section, (unless new parts with

preapplied locking compound are being used).

Thread debris screen hex studs into mounting holes

in fl ywheel. Torque each stud to 9.9 N·m (88 in. lb.).

3. Install stiffener followed by metal debris screen onto

studs. Secure with special washers and mounting

screws using Loctite

®

243™ Threadlocker on

threads. Torque screws to 9.9 N·m (88 in. lb.).

Install Electric Starter

1. Install electric starter motor using screws.

2. Torque screws to 15.3 N·m (135 in. lb.).

3. Connect leads to solenoid.

Install Valley Baffl es

1. Install valley baffl es and secure with mounting

screws. Lower section should fi t under outer baffl e.

Torque M6 screws going into cylinder head to 10.7

N·m (95 in. lb.) for new holes, or 7.3 N·m (65 in. lb.)

for used holes. Start upper M6 screws only if main

control bracket rear supports attach to these screws.

2. Torque M6 screw going into lower blower housing

mounting clip to 2.5 N·m (22 in. lb.).

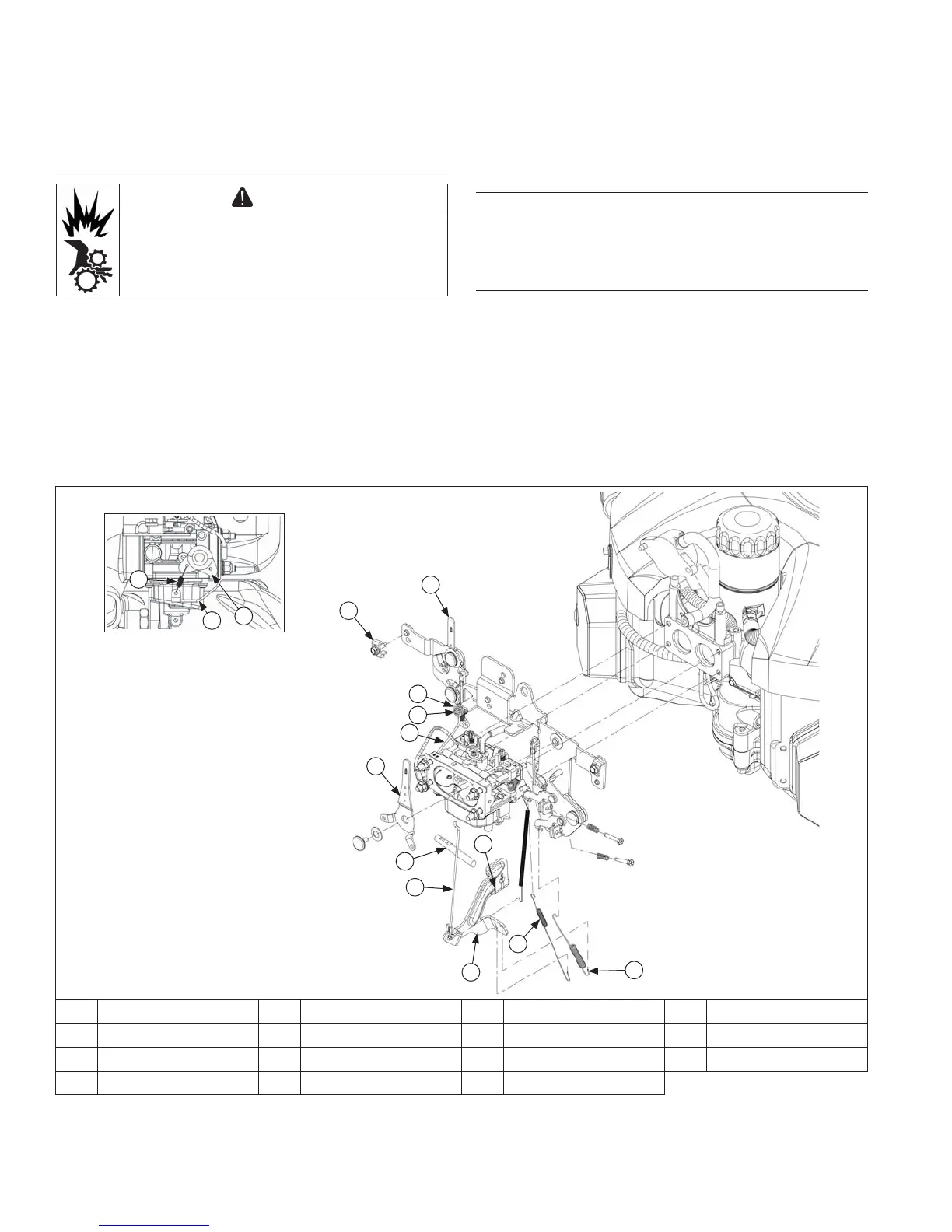

Control Bracket Components

G

E

F

A

I

H

N

M

O

C

D

B

K

L

J

A Throttle Lever B Throttle Linkage C Nut D Governor Arm

E Governor Spring F Governed Idle Spring G Cross Shaft H Governor Lever

I Choke Cable Clamp J Control Pivot Pin K Pal Nut L Choke Linkage

M Choke Return Spring N Choke Bracket O Choke Lever

Loading...

Loading...