Reassembly

6162 690 02 Rev. D KohlerEngines.com

Valve Stem Seals

These engines use valve stem seals on intake and

exhaust valves. Always use new seals whenever valves

are removed from cylinder head. Seals should also be

replaced if worn or damaged. Never reuse an old seal.

Assemble Cylinder Heads

Prior to installation, lubricate all components with engine

oil, paying particular attention to lip of valve stem seal,

valve stems, and valve guides. Install in order listed

below using a valve spring compressor.

● Intake and exhaust valves

● Valve spring retainers.

● Valve springs.

● Valve spring keepers.

● Valve stem seals.

● Guide plate.

● Pivot studs.

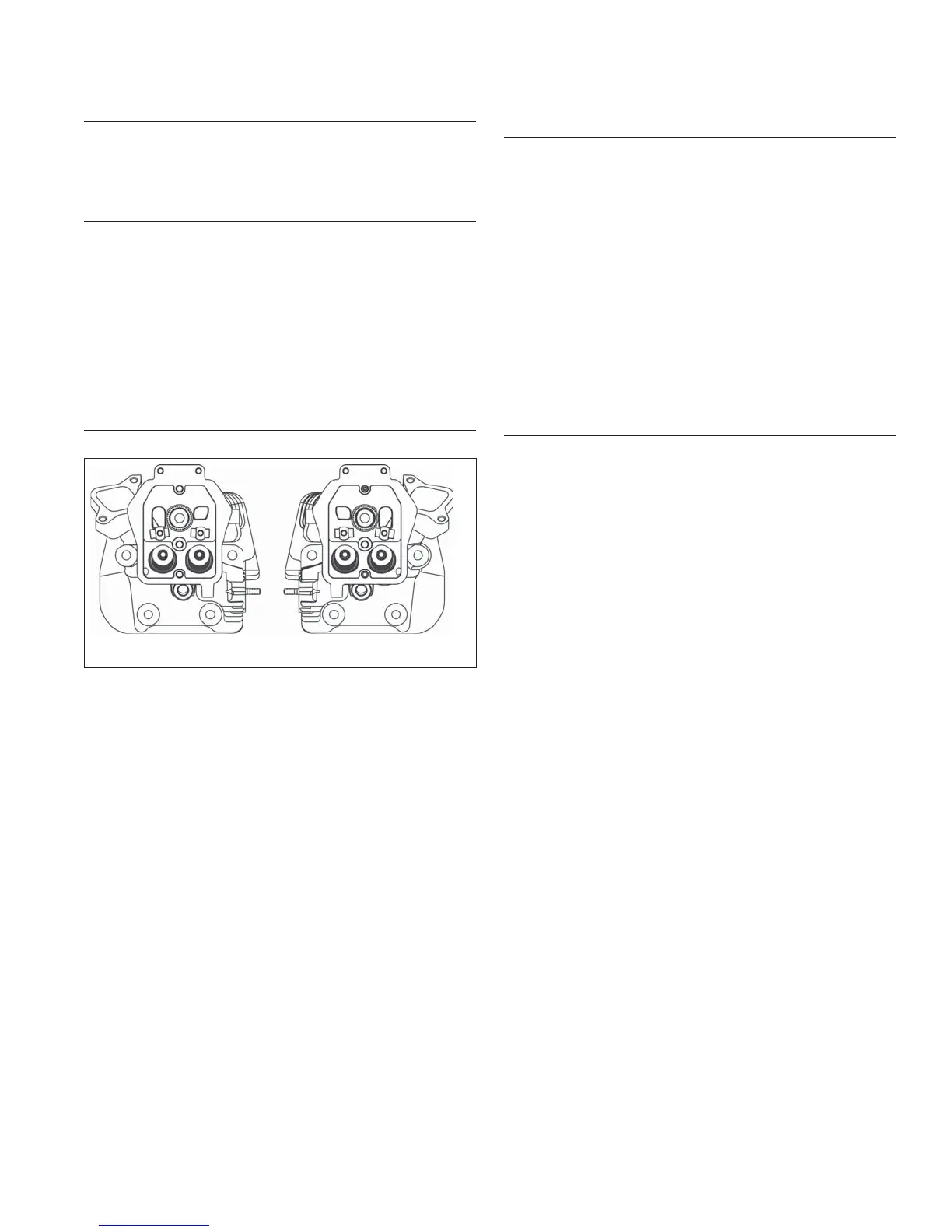

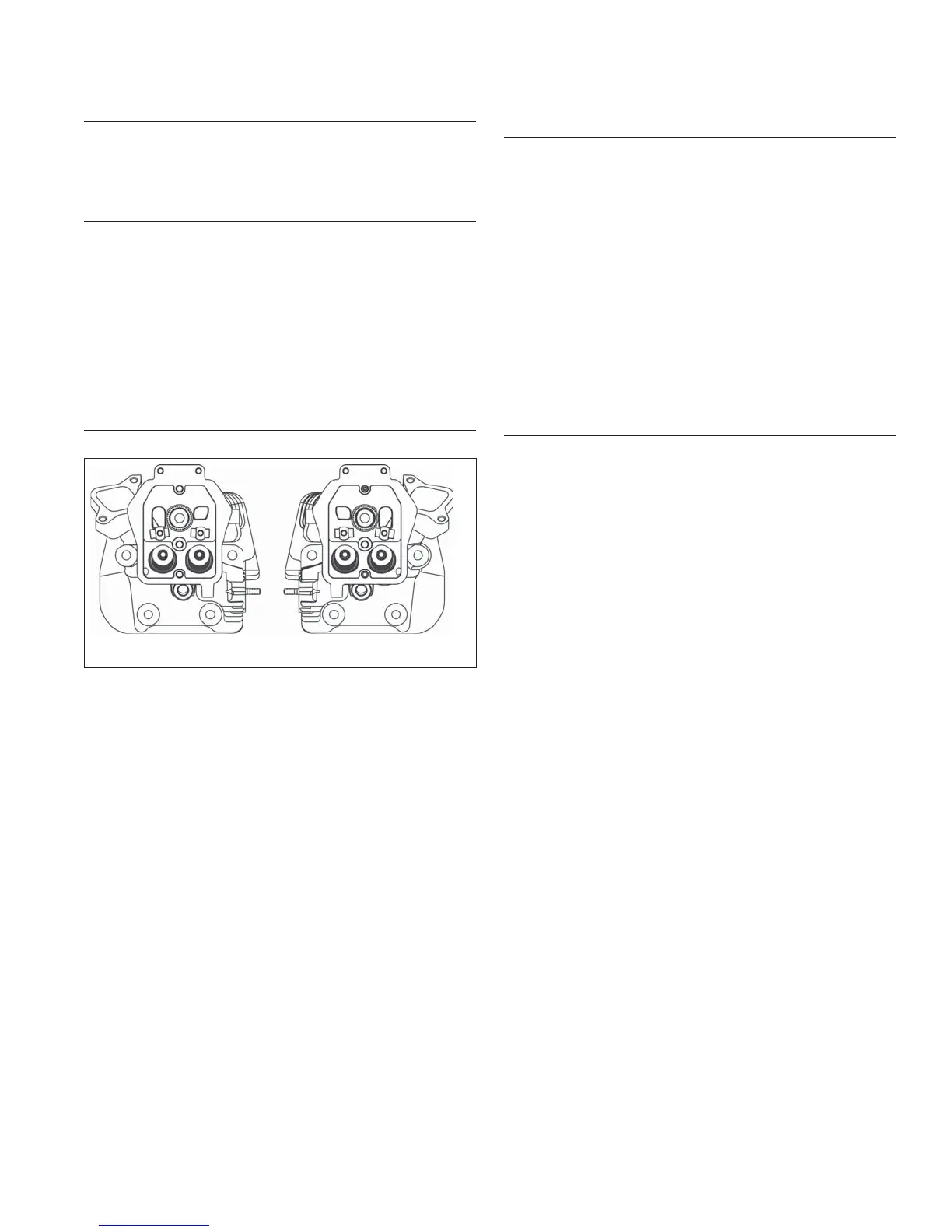

Install Cylinder Heads

Torque Sequence

12

2

2

4

4

5

5

3

3

1

1

NOTE: Match numbers embossed on cylinder heads

and crankcase.

1. Check to make sure there are no nicks or burrs on

sealing surfaces of cylinder head or crankcase.

2. Check dowel pins are in place in 2 lower locations,

and install a new cylinder head gasket, (printed side

up).

3. Install cylinder head. Make sure head is fl at on

gasket and dowel pins. Install a fl at washer on

screws in locations 1 and 3. Install spacer followed

by a fl at washer on screw in location 5. Start 5

screws.

4. Torque screws in 2 stages, fi rst to 22.6 N·m

(200 in. lb.), fi nally to 45.2 N·m (400 in. lb.) following

sequence shown.

5. Repeat procedure for opposite cylinder.

6. Make sure threads of pipe plugs for cylinder heads

are clean and dry. Install a plug into each cylinder

head above screw on location 2 and torque to

28.25 N·m (250 in. lb.).

Install Guide Plate, Pivot Studs, Push Rods and

Rocker Arms

NOTE: Install push rod guide plate so fl ange is down

(towards cylinder) on side 1, and up (away from

cylinder) on side 2.

NOTE: Push rods should always be installed in same

position as before in disassembly.

1. Install push rod guide plate and rocker arm pivot

studs onto cylinder heads if removed previously.

Torque studs to 11.3 N·m (100 in. lb.).

2. Note mark or tag identifying push rod as either

intake or exhaust and cylinder 1 or 2. Dip ends of

push rods in engine oil and install, making sure each

push rod ball seats in its hydraulic lifter socket.

3. Apply grease to contact surfaces of rocker arms and

rocker arm pivots. Install rocker arms, rocker arm

pivots, and adjusters on cylinder head 1.

Adjust Valve Clearance

NOTE: It takes two hands to make lash adjustment. A

clamping device or an assistant to hold lifter

compressed while making adjustment will make

process easier.

1. Turn adjusters in rocker arms by hand clockwise

(down), only enough to capture push rods in

recesses.

2. Rotate crankshaft to establish TDC on compression

stroke for cylinder 1.

Check for:

a. Compression will be felt through spark plug hole.

b. Keyway of crankshaft will be aligned with cylinder

1.

c. No rocker arm/push rod movement if crankshaft

is rotated slightly back and forth. If they are

moving, rotate crankshaft one full revolution.

3. Pre-Bled Lifters:

a. Apply downward pressure to push rod side of

rocker arm to compress lifter and bottom internal

plunger. Several manual compressions may be

necessary. Hold in this position for step 3b.

b. Insert a 0.127 mm (0.005 in.) feeler gauge

between end of one valve and rocker arm. Turn

adjuster until a slight drag is felt. Hold adjuster in

this position and tighten locking setscrew. Torque

setscrew to 7.3 N·m (65 in. lb.). After tightening

recheck adjustment. Proper valve clearance is

0.101/0.152 mm (0.004/0.006 in.).

c. Repeat procedure for other valve on this side.

Non-Bled Lifters (when cylinder heads and lifters are

not removed):

a. Turn 1 rocker arm adjusting nut from side 1 down

until push rod is snug but can be rotated with

drag. This is 0 lash.

b. Mark or note setting of adjustment nut, then turn

(tighten) adjuster nut 4 complete revolutions

clockwise, plus one fl at of nut (1/6 turn), or a total

of 4-1/6 turns.

Loading...

Loading...