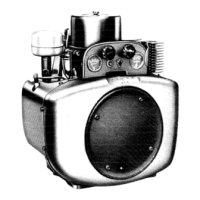

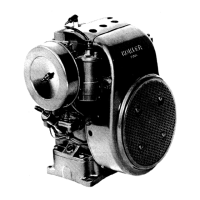

How to troubleshoot a Kohler KD 425-2 that does not start?

- BBryan MartinezJul 31, 2025

If your Kohler Engine doesn't start, several issues within the fuel circuit could be the cause. Begin by inspecting the fuel circuit for clogged pipes, a clogged fuel filter, or air inside the circuit. Also, check for a clogged tank breather hole, a faulty fuel pump, or a jammed injector. Furthermore, examine the injection pump delivery valve and control for any jamming, ensure the injector setting and injection pump setting are correct, and check for excessive plunger blow-by.