Maintenance

Lubricants and operating fluids

– Sulfur content factor is defined in the table on KD fuel sulfur content factors (see: tab. 35,

page 149).

As an example:

– Standard oil change interval is 500 operating hours.

– Oil category is 3, so oil category factor is 2.

– Sulfur content is 1.3%, so sulfur content factor is ¼.

– Change interval = 500 * 2 * 1/4 = 250 hours

Lubricating oil monitoring

Close monitoring of lubricating oil quality brings benefits in several areas:

– Optimization of oil-change intervals

· Improves your economics

· Reduces environmental footprint

– Optimization of diesel engine availability

– Early detection of potential damage

When one of these criteria is no more fulfilled in operating lubricating oil, oil must be changed

immediately:

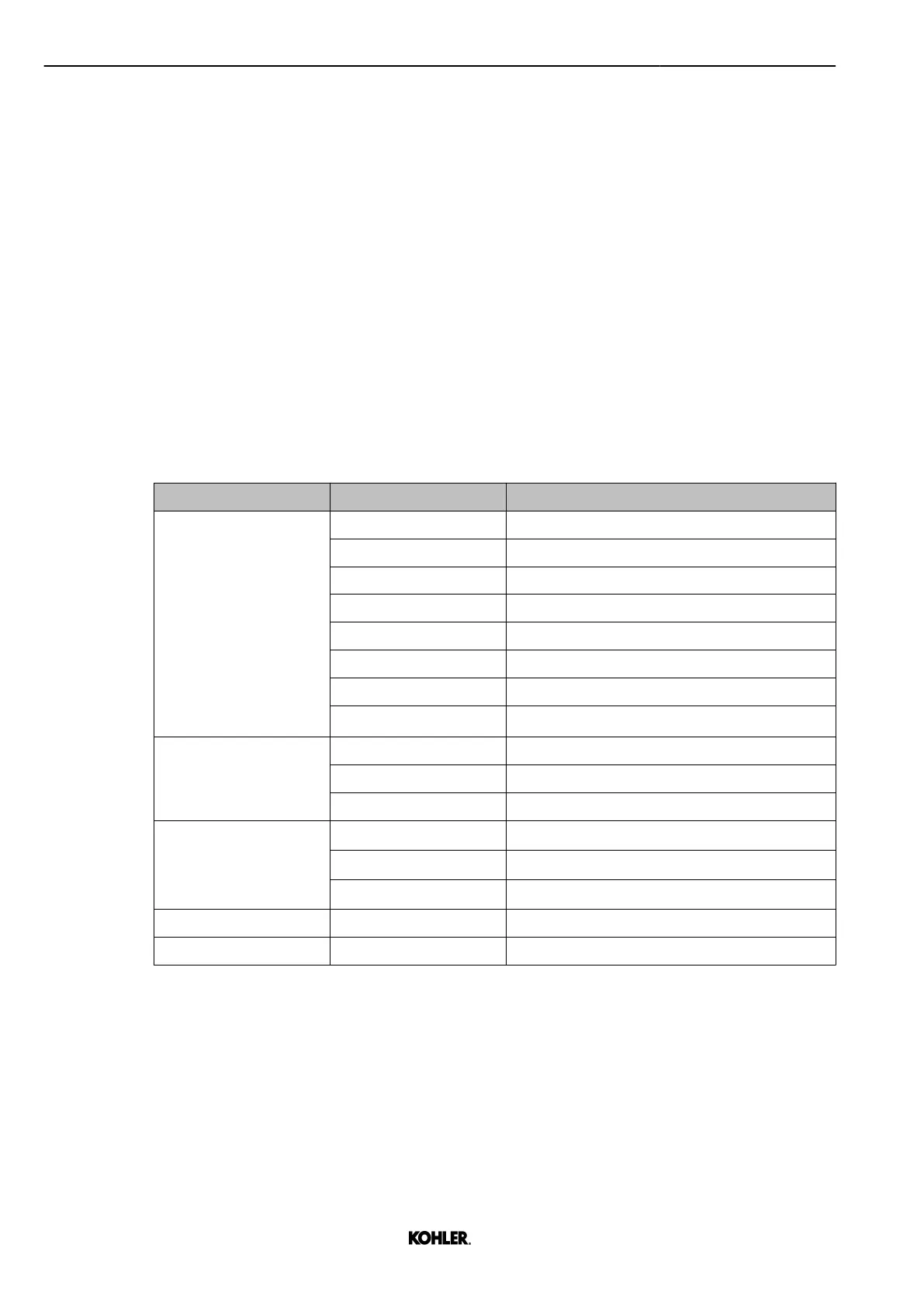

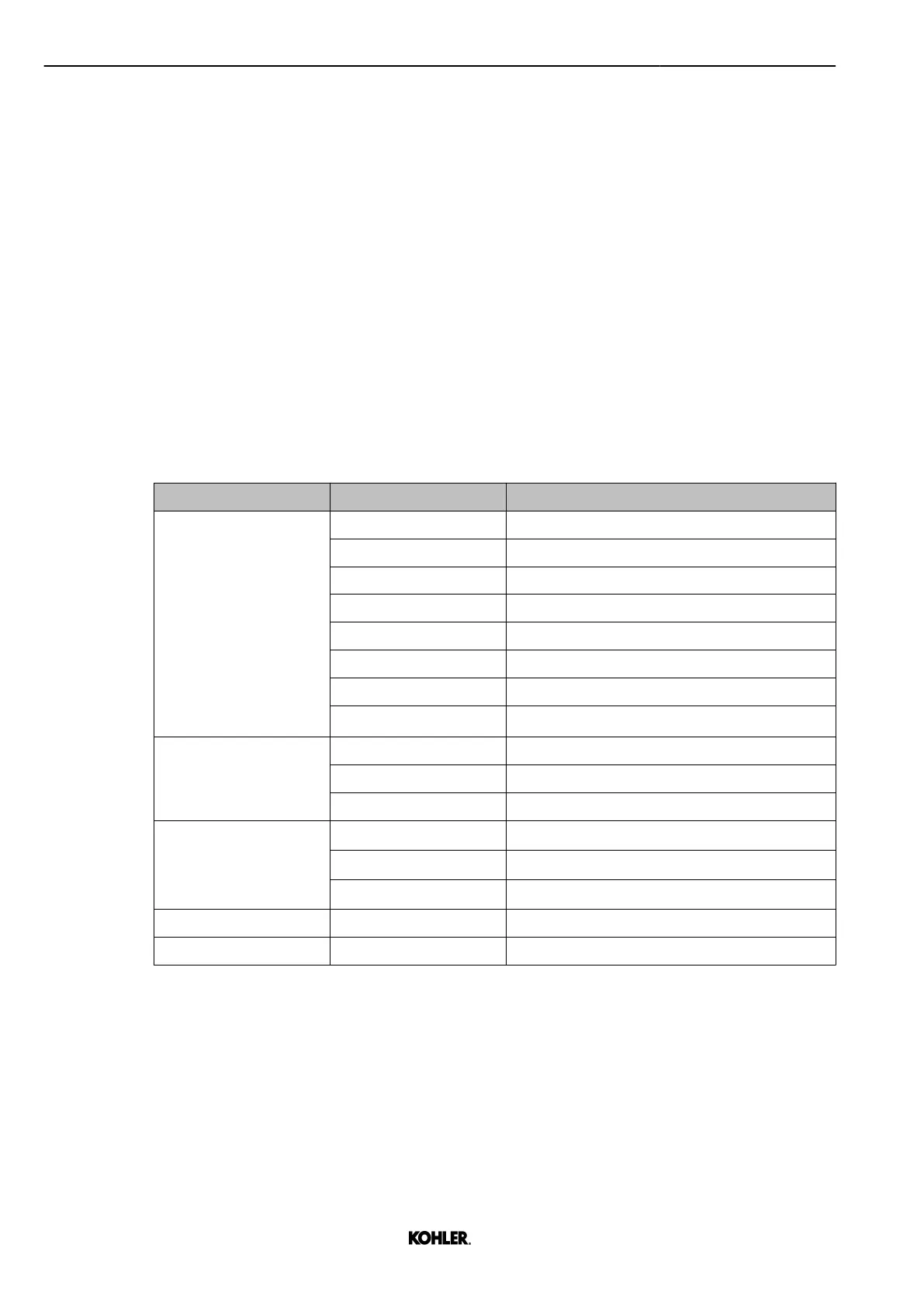

Criteria group

Criteria Maximum values

Contaminants Aluminum < 15 ppm

Iron < 40 ppm

Chromium < 10 ppm

Copper < 20 ppm

Lead < 25 ppm

Silicon < 15 ppm

Sodium < 20 ppm

Potassium

A)

< 25 ppm

A)

Other contaminants Water < 0.2%

Carbon < 3%

Fuel < 3%

Viscosity @ 40 °C (104 °F) 0.9 V

0

< V < 1.1 V

0

(V

0

= fresh oil viscosity

@ 100 °C (212 °F) 0.9 V

0

< V < 1.1 V

0

(V

0

= fresh oil viscosity

Viscosity index 0.88 Vi

0

< Vi < 1.12 Vi

0

(Vi

0

= fresh oil viscosity

Acid / Basic TAN & TBN TAN < TBN - 2 mgKOH/g

Oxidation < 25 abs.cm

-1

Tab. 36: KD lubricating oil change criteria

A)

Potassium is now incorporated in new-generation lubricating oils; conclusion must be

drawn only by having initial composition and evolution available.

Mineral lubricating oils

The use of mineral lubricating oils is strictly forbidden in Kohler KD diesel engines.

152

© 2022 by Kohler Co. All rights reserved.

KD62V12 33521030301_8_1 EN_US 2022-09

Loading...

Loading...