5

INFORMATION ABOUT MAINTENANCE

EN 34

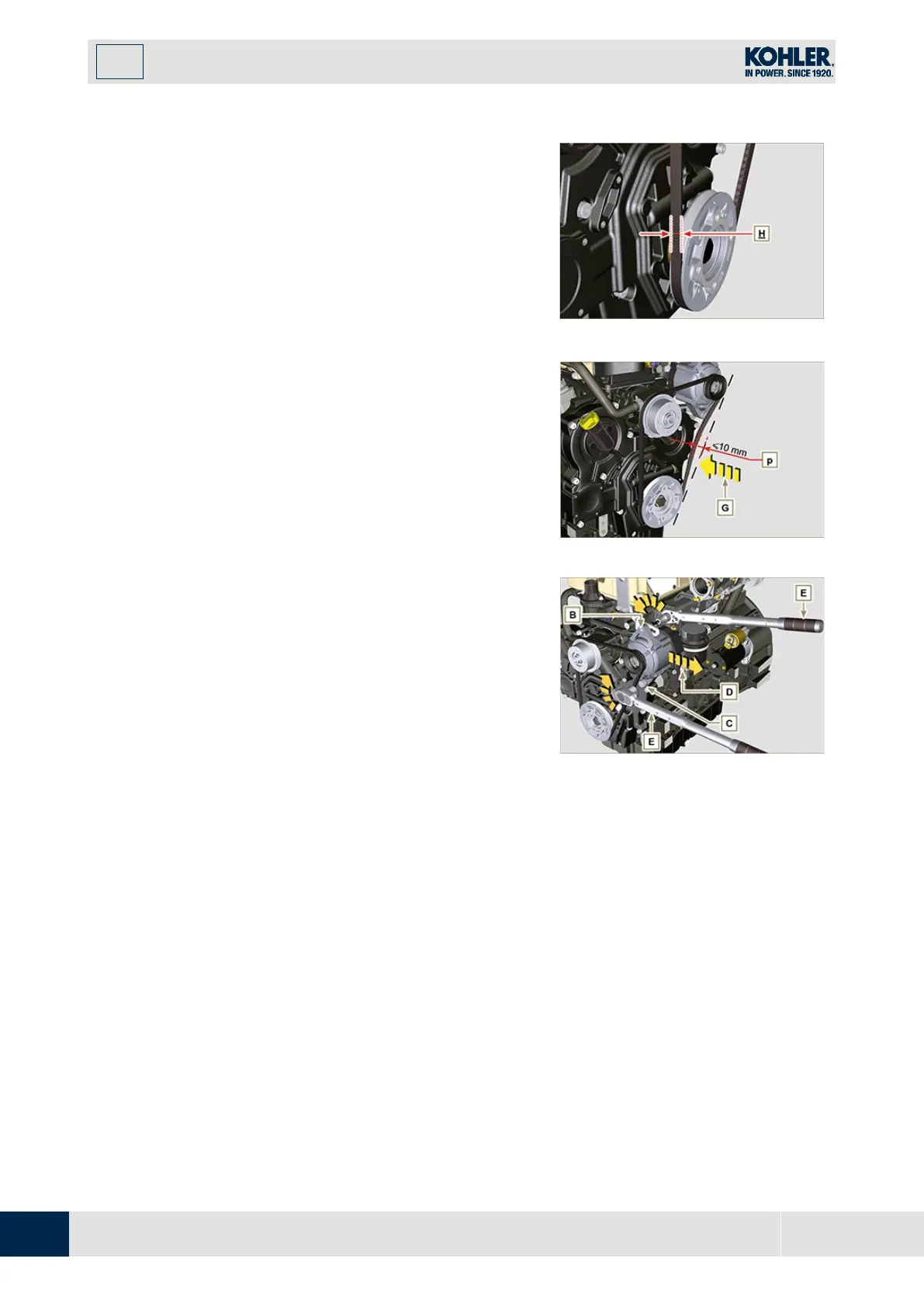

Should the correct tool not be available, the belt tension can

be checked by applying a force in the direction of arrow

G

of

approx' 10kg on the point

p

. When correctly tensioned the belt

must show a movement of less than

10 mm.

If not adjust it.

Fig 5.11

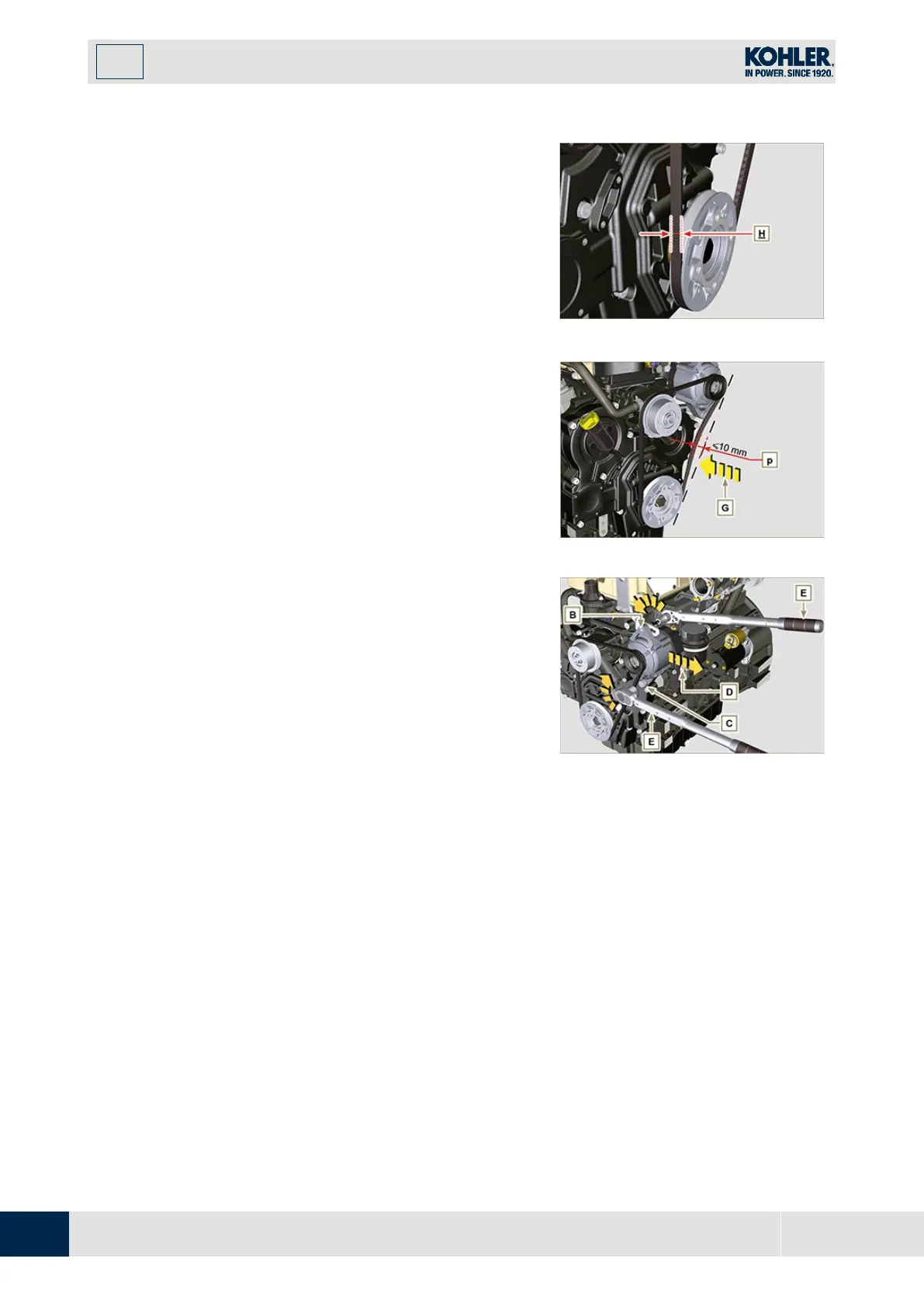

1.

Loosen the fastening bolts B e C.

2.

Pull the alternator outwards (in direction of the arrow D

), to tension the belt.

3.

Tension the belt tightening the bolts B e C.

4.

Tighten bolts B (tightening torque of 25 Nm) and C

(tightening torque at 69 Nm [thread M10] - 40 Nm

[thread M8]) in sequence with a torque wrench E.

5.

Check by the appropriate tool that at point p the

tension value is between 70 and 75 Hz for V-belt of 9

mm and 80 and 85 Hz for V-belt of 17 mm (Fig. 5.10)

(H).

Using the tool

F (DENSO BTG-2)

shown in the picture (or a

similar one) it is possible to check the corresponding value in

Newton, (which should be) included between

200 and 230 N

for V-belt of

9 mm and 350 and 450 N

for V-belt of

17 mm

(H)

.

Should the correct tool not be available, the belt tension can

be checked by applying a force in the direction of arrow

G

of

approx' 10kg on the point p. When correctly tensioned the belt

must show a movement of less than 10mm.

Let the engine run for some minutes, then let it cool down at

ambient temperature and repeat the operations

2, 3, 4 and 5

in

case the belt tension results out of the above mentioned

values.

NOTE:

Contact

KOHLER

authorised workshops for

replacement.

Fig 5.12

Fig 5.13

Loading...

Loading...