2

TECHNICAL INFORMATION

EN 12

2.5 Fuel

Important

•

Use of other types of

fuel could damage the

engine. Do not use dirty

diesel fuel or mixtures

of diesel fuel and water

since this will cause

serious engine faults.

• Clean fuel prevents the fuel injectors from clogging.

Immediately clean up any spillage during refuelling.

• Never store diesel fuel in galvanized containers (i.e. coated

with zinc). Diesel fuel and the galvanized coating react

chemically to each other, producing flaking that quickly

clogs filters or causes fuel pump and/or injector failure.

• Any failure resulting from the use of fuel other than Tab. 2.3,

2.4 will not be covered by warranty.

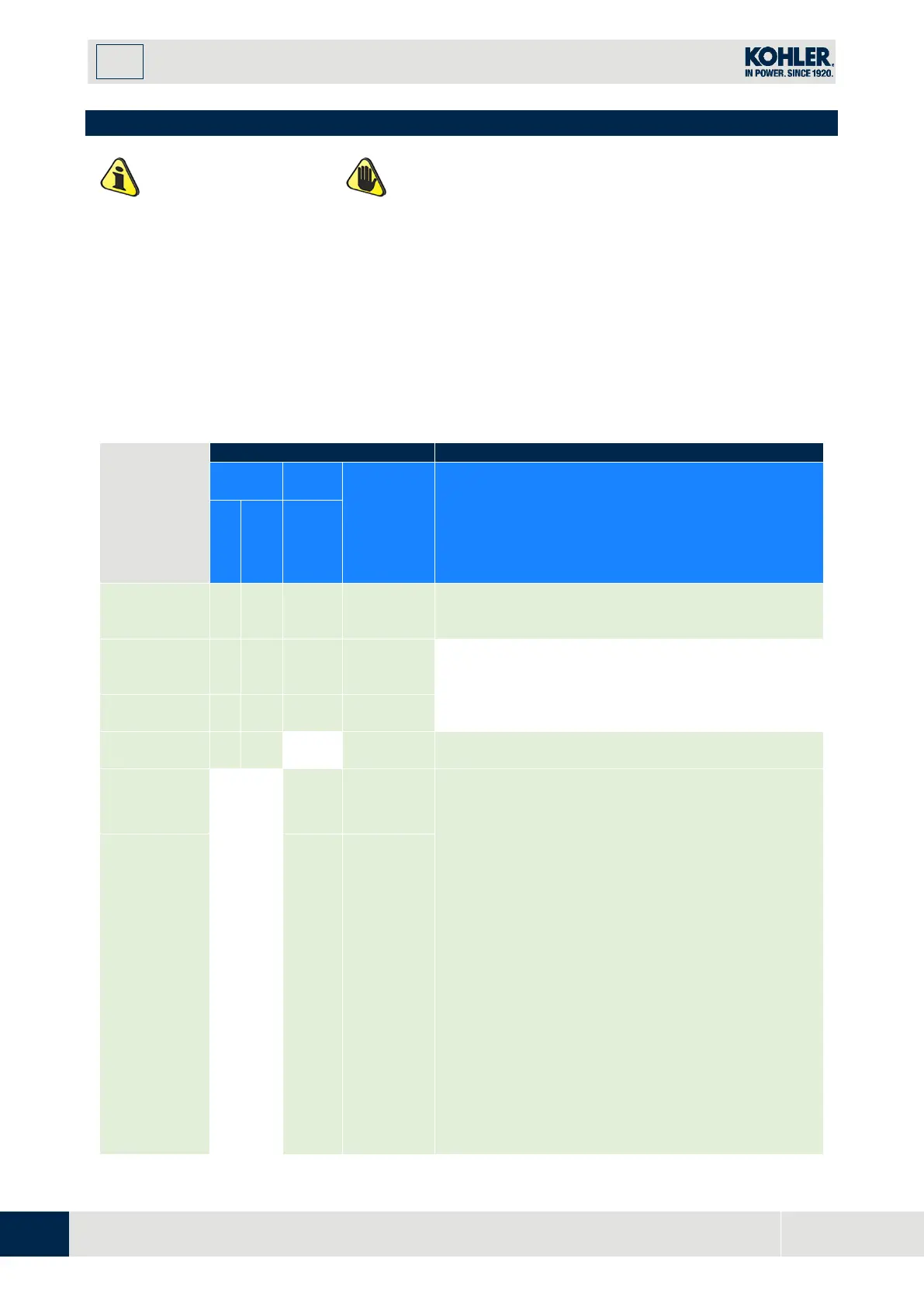

Cetane number of 40 minimum. Cetane number greater than 47 is preferred, especially for

temperatures below –20 °C (–4 °F) or elevations above 1675 m (5500 ft.).

2.3

Fuel Type

|

|

V

no

certificatio

n (*1)

*1: the regions known as poor lubricity diesel fuel

quality or if the engine is operated with Jet fuels,

the primary filter must be with lubricity dosing

capability. Contact Kohler for information about

the approved filter for this purpose.

5

3A III

100% (EN

Power and torque might be 1% to 5% lower due to

low fuel density compared to standard diesel fuel.

Fuel F-

Do NOT USE vegetable oils as a biofuel not compliant

with EN590 prescription.

Grade 1-D

S15

For ambient temperatures below 0°C (32°F) with no

arctic fuel available (Grade 1-D S15, Grade 2-D S15,

ASTM D 975) use the following additives to prevent

possible engine damage with low engine load in cold

weather:

Power Service Diesel Fuel Supplement+Cetane Boost

Different additives are not allowed.

The use of approved additives has no impact on the

engine maintenance schedule.

Do NOT USE vegetable oils as a biofuel not compliant

with ASTM D975 Grade1 and Grade2 prescription.

Grade 2-D

S15

Loading...

Loading...