2.8 Trouble shooting

Depending on the conditions in your installation, there may be a wide variety of reasons for the fault. In multi-axis

systems there may be further hidden causes of a fault.

Eliminate errors and faults in compliance with work safety rules. Troubleshooting only by

qualified and trained staff.

Detailled hints for removal of faults can be found in the online help chapter "Trouble-Shoot-

ing". Our customer service can give you further assistance with problems.

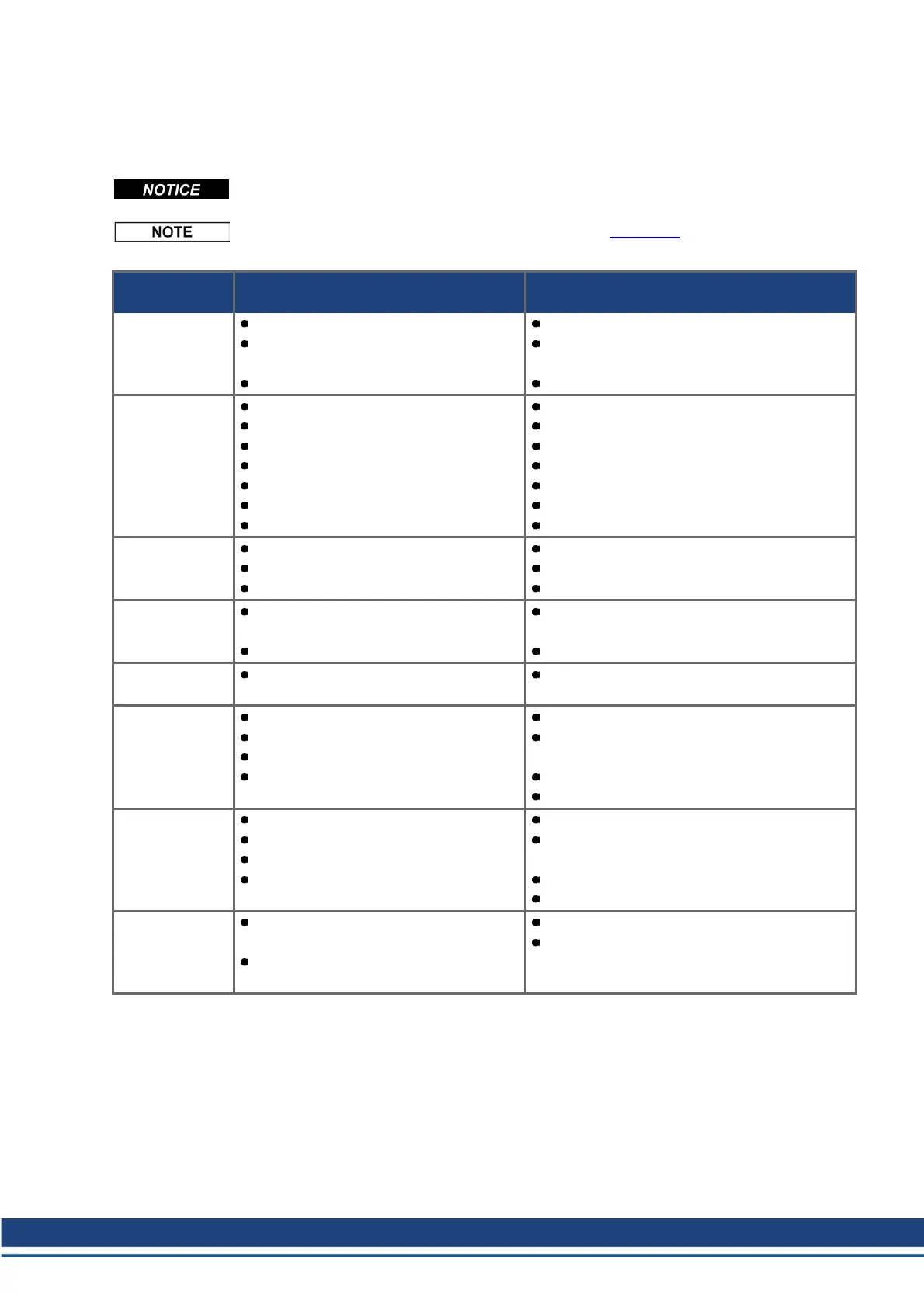

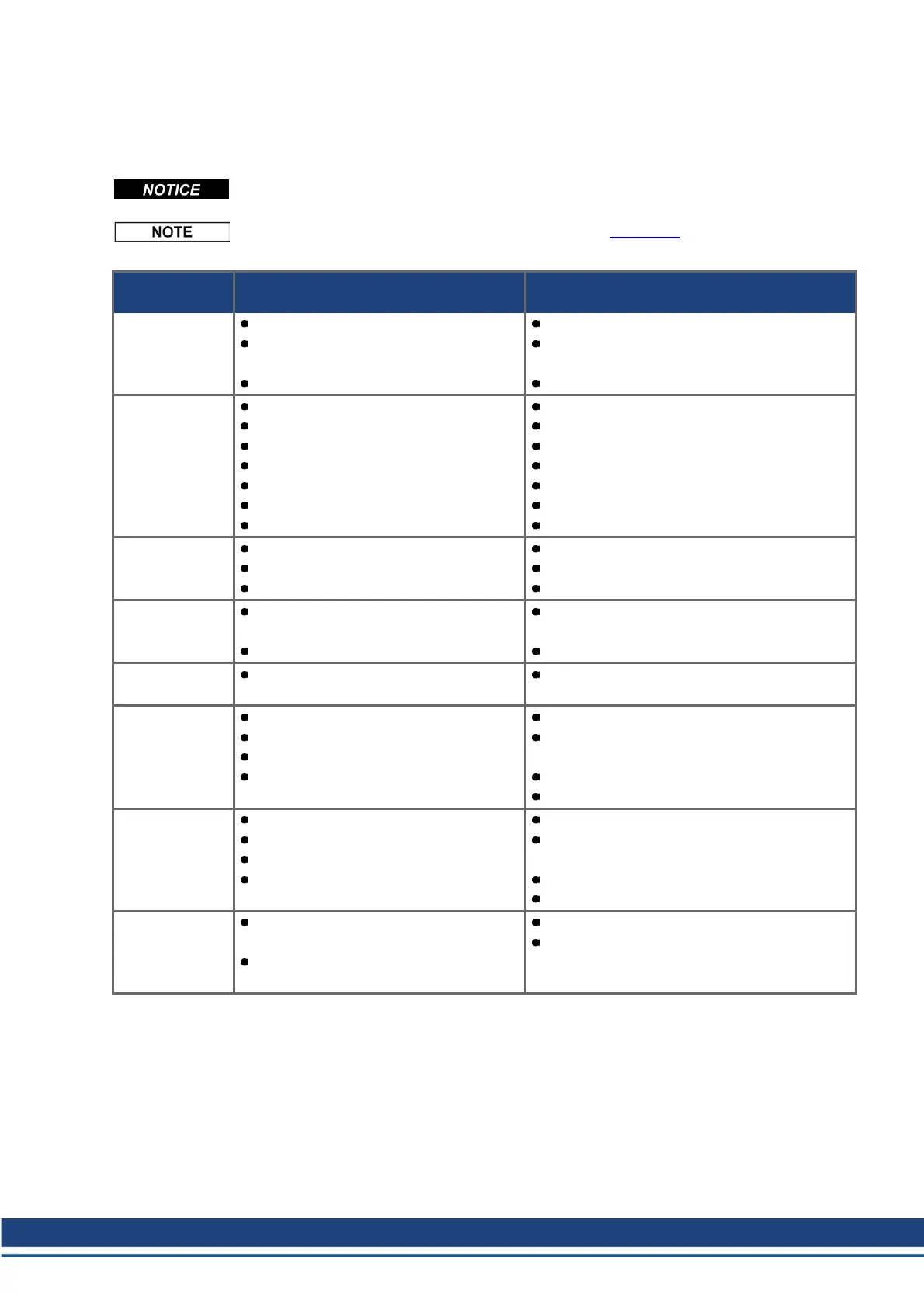

Fault Possible causes Measures to remove the cause of

the fault

HMI message:

communication

fault

wrong cable used

cable plugged into wrong position in

servo amplifier or PC

wrong PC interface selected

use null-modem cable

plug cable into the correct sockets on the

servo amplifier and PC

select correct interface

Motor does not

rotate

servo amplifier not enabled

break in setpoint cable

motor phases swapped

brake not released

drive is mechanically blocked

no. of motor poles set incorrectly

feedback set up incorrectly

apply enable signal

check setpoint cable

correct motor phase sequence

check brake control

check mechanism

set no. of motor poles

set up feedback correctly

Motor oscil-

lates

gain too high (speed controller)

shielding in feedback cable is broken

AGND not wired up

reduce Kp (speed controller)

replace feedback cable

join AGND to CNC-GND

Drive reports

following error

I

rms

or I

peak

is set to low

setpoint ramp is too long

increase I

rms

or I

peak

(keep within motor lim-

its!)

shorten setpoint ramp +/-

Motor over-

heating

I

rms

/I

peak

set too high reduce I

rms

/I

peak

Drive too soft Kp (speed controller) too low

Tn (speed controller) too high

ARLPF / ARHPF too high

ARLP2 too high

increase Kp (speed controller)

use motor default value for Tn (speed con-

troller)

reduce ARLPF / ARHPF

reduce ARLP2

Drive runs

roughly

Kp (speed controller) too high

Tn (speed controller) too low

ARLPF / ARHPF too low

ARLP2 too low

reduce Kp (speed controller)

use motor default value for Tn (speed con-

troller)

increase ARLPF / ARHPF

increase ARLP2

Axis drifts at

setpoint = 0V

offset not correctly adjusted for analog

setpoint provision

AGND not joined to the CNC-GND of

the controls

adjust setpoint-offset (analog I/O)

join AGND and CNC-GND

S700 Safety Guide | 2 English

Kollmorgen | wiki-kollmorgen.eu | February 2017 73

Loading...

Loading...