PC800, 850-8 9

30 Testing and adjusting SEN00786-02

Adjusting valve clearance

a Adjusting tools for valve clearance

1. Remove the engine hood assembly and muffler

(7).

4 Engine hood assembly: 340 kg

2. Remove all cylinder head covers (1).

3. Rotate the crankshaft in the normal direction to

align [1.6 TOP] line (a) on the damper with

pointer (2), and set the No.1 cylinder compres-

sion to top dead center.

a Check the pointer from the alternator side.

a Crank the engine with the hexagonal part at

the water pump drive shaft on the alternator

side.

a At the compression top dead center, the

rocker arm of the No. 1 cylinder can be

moved by hand an amount equal to the valve

clearance. If the rocker arm does not move,

it is not at the compression top dead center,

so rotate the crankshaft one more turn.

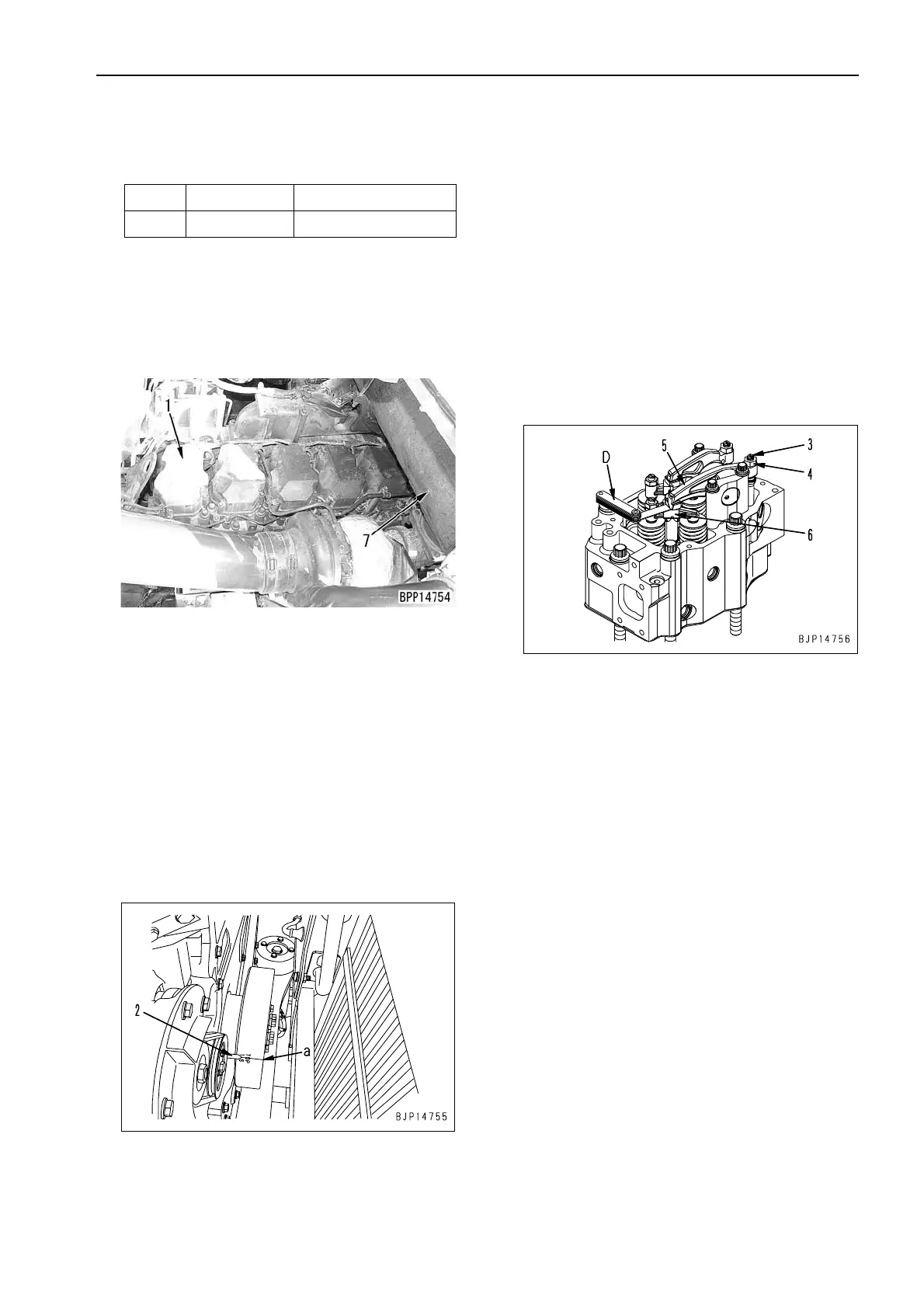

4. Insert clearance gauge D in clearance (b)

between rocker arm (5) and crosshead (6), and

turn adjustment screw (3) to adjust the valve

clearance.

a With clearance gauge D inserted, turn the

adjustment screw and adjust until the clear-

ance is a sliding fit.

a Valve clearance:

Intake valve: 0.35 mm, Exhaust valve: 0.57 mm

5. Tighten locknut (4) to hold adjustment screw (3)

in position.

3 Locknut:

45.1 – 51.0 Nm {4.6 – 5.2 kgm}

a After tightening the locknut, check the valve

clearance again.

6. Rotate the crankshaft 120° each time in the nor-

mal direction and repeat Steps 2 - 4 to adjust the

valve clearance of each cylinder according to

the firing order.

a Firing order: 1-5-3-6-2-4

7. After completing the adjustment, set to the origi-

nal condition.

3 Mounting bolt of cylinder head cover:

29.4 – 34.3 Nm {3.0 – 3.5 kgm}

Symbol Part No. Part Name

D Purchased Clearance gauge

Loading...

Loading...