16 PC800, 850-8

SEN00794-02 40 Troubleshooting

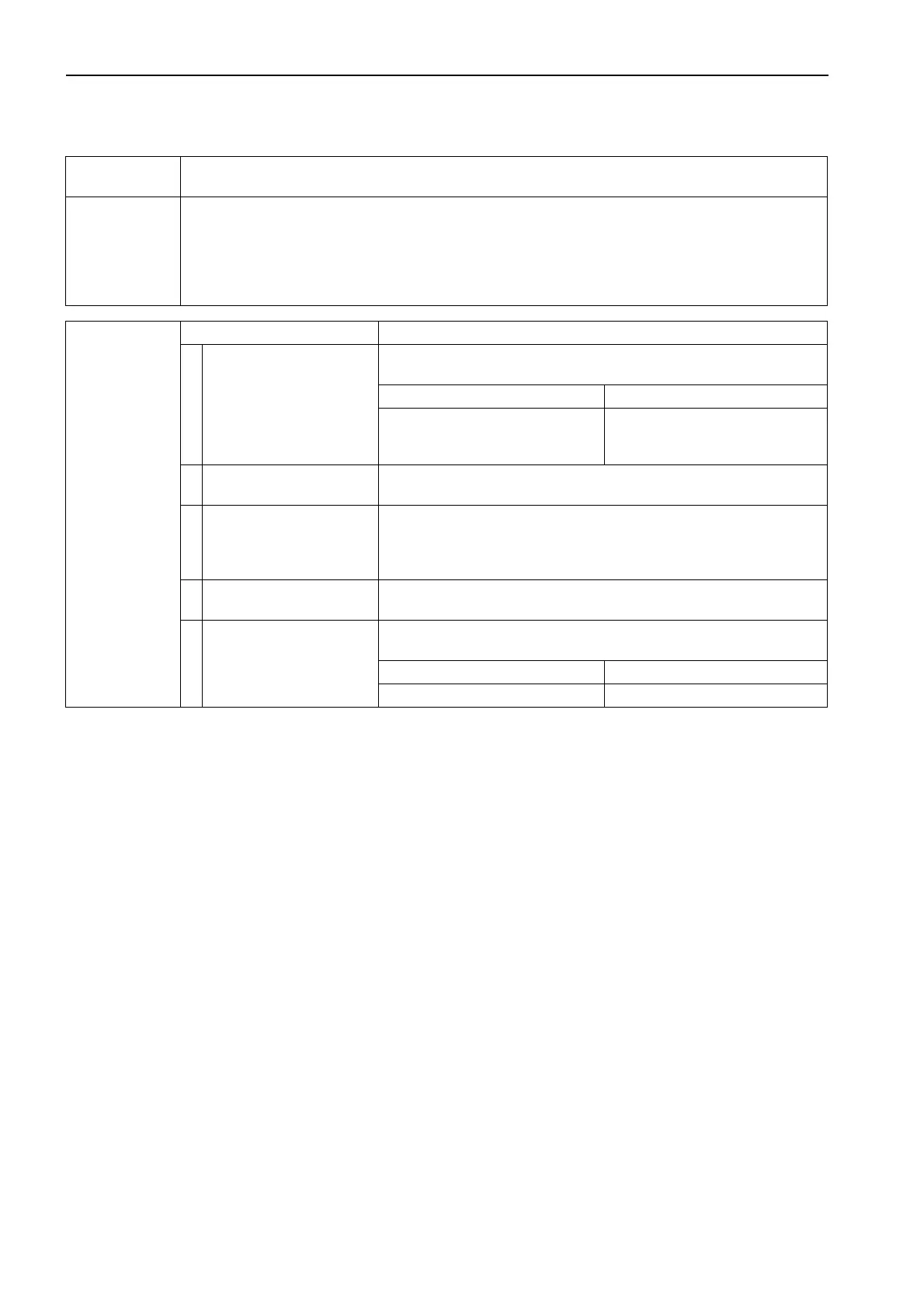

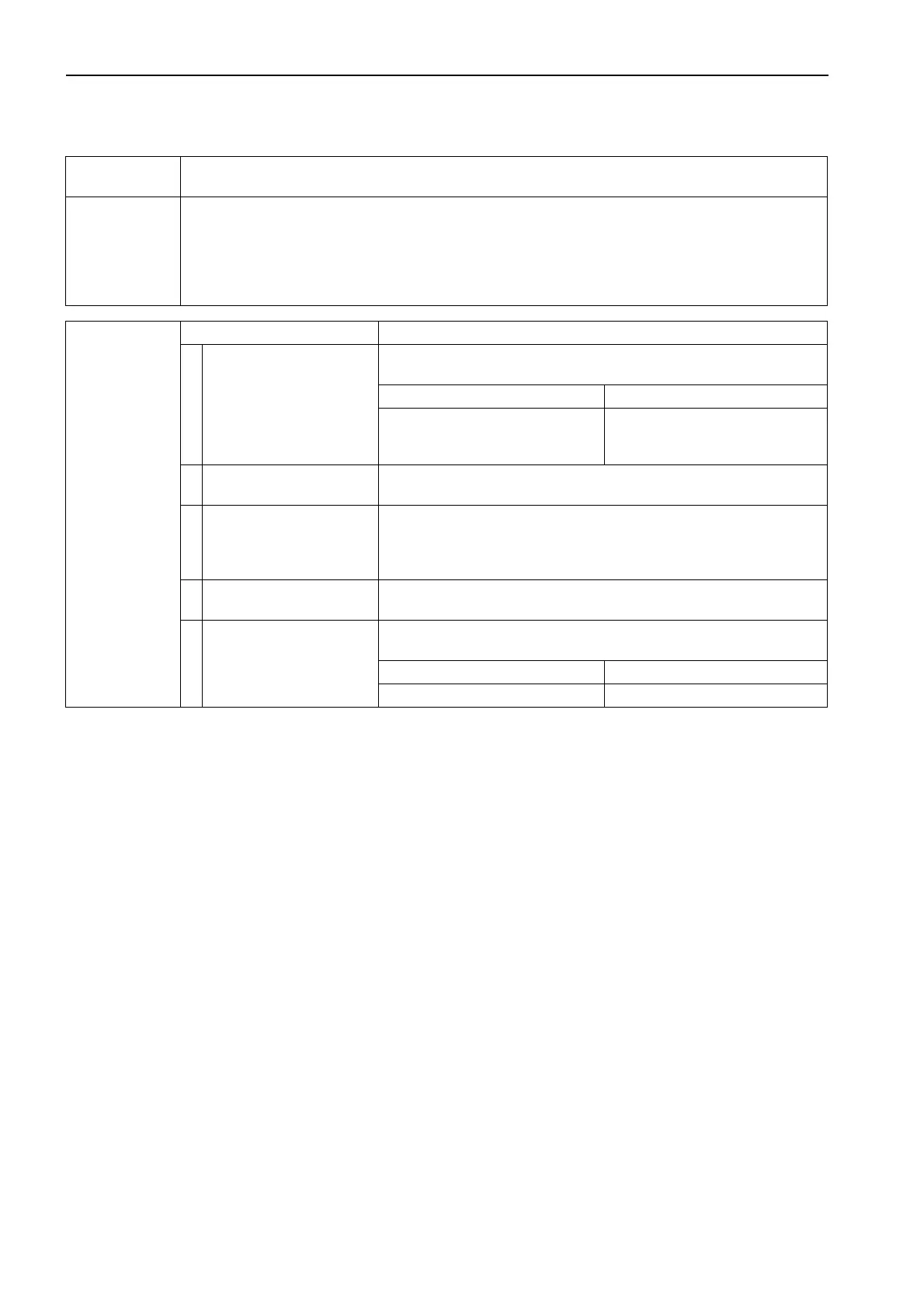

H-6 Speed or power of arm is low

Failure

phenomenon

• Speed or power of arm is low

Relative

information

• Check that the speeds of the other work equipment, travel, and swing are normal.

(If they are abnormal, carry out the related troubleshooting.)

• Check that the machine does not deviate.

(If the machine deviates, carry out the related troubleshooting.)

• Carry out all the troubleshooting in working mode P.

• Before carrying out troubleshooting, check that electric circuit related to arm control is normal.

Possible causes

and standard

value in normal

state

Cause Standard value in normalcy and references for troubleshooting

1

Malfunction of left PPC

valve (arm circuit)

aPrepare with the engine stopped, then carry out troubleshooting with

the engine at high idle.

L.H. work equipment control lever PPC valve output pressure

Arm IN, OUT

Full stroke

2.9 MPa

{30 kg/cm

2

}

2

Malfunction of arm

control valve (spool)

Since the spool of the arm control valve (Lo, Hi) may have a malfunc-

tion, check it directly.

3

Malfunction of arm

control valve

(safety & suction valve)

The safety-suction valve of the arm control valve (Lo, Hi) may malfunc-

tion. Check it directly. (After checking the safety-suction valve by

exchanging it with a valve of another work equipment circuit, be sure to

return it since its set pressure is different from others.)

4

Defective arm control valve

(body)

Since the body of the arm control valve (Lo, Hi) may have a malfunction,

check it directly.

5

Defective seal of arm

cylinder

aPrepare with the engine stopped, then carry out troubleshooting with

the engine at high idle.

L.H. work equipment control lever Leakage from cylinder

Relieved in arm IN position Max. 20 cc/min

+0.8

–0.2

+8

–2

Loading...

Loading...