RWCP, RWCN

10

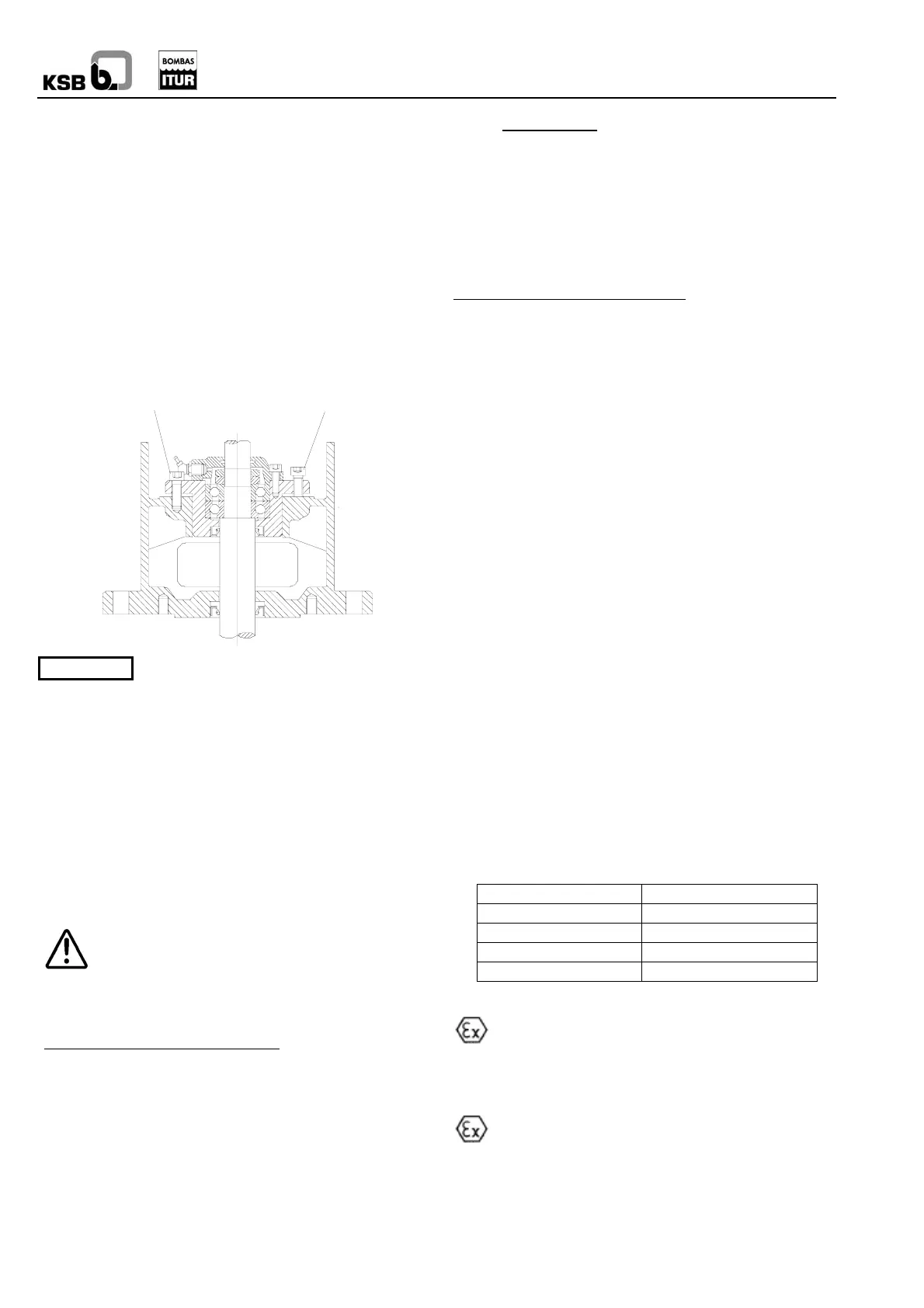

6.1.4 Impeller adjustment

Turn the pump shaft by hand to check that the rotor is not

blocked. Should interior contact in the pump be detected,

carry out an axial regulation. To do this:

- Release the attachment screws (2)

- Tighten the adjusting screws (1) to slightly raise the

whole moving section.

- Turn the shaft again by hand and check that the rotor

rotates freely without any internal contact. If there

continues to be contact, tighten a little more using the

adjusting screws.

- Tighten the attachment screws (2) to fix the position

reached.

2

If a mechanical seal is used, remove it first

before regulating. Please contact us before

carrying out this operation.

6.1.5 Start-up

Before starting up the group, check all the sections with

regards to chapter 6.

The start-up must be carried out with the suction valve (where

fitted) completely open and the impulsion valve partially

closed. Once the pump has reached its service speed and the

suction air has been eliminated, regulate the operation point

using the impulsion valve.

If the electric motor guard is triggered when starting up, close

the impulsion valve more until the equipment starts up

normally.

The pump must NEVER work with zero flow or flow

which is less than the operating minimum, as internal

recirculation will cause the fluid to heat up quickly,

leading to hazards (including explosion) as a result of the high

pressures reached within the frame. Check the minimum flow

in the operation curves.

Minimum flow necessary for the pump

The pumps cannot work below the minimum flow specified in

the datasheets.

If this condition may come about, the installation must be fitted

with safety devices which prevent the operation of the pump

without liquid inside, or have automatic devices to discharge

the minimum flow of the pump.

For liquids other than water, the minimum flow is determined

by the following formula:

Qmin =

3.600.000 x Pa

Pe x Ce

In which:

Qmin: Minimum flow in m

3

/h.

Pa: Power absorbed by the pump in kW at closed valve.

Ce: Specific heat of the fluid in J/kg*ºC.

Pe: Specific weight of the fluid in kg/m

3

Maximum flow permitted by the pump

Unless indicated in another datasheet, the maximum flow

permitted is 1.1x optimum flow of the pump with the supplied

impeller diameter.

6.1.6 Shutdown

Close the impulsion pipe valve.

If there is anti-return in impulsion with counter pressure, leave

the impulsion valve open.

- Shutdown the motor. Check that shutdown is normal.

- In prolonged periods of non-operation, close the suction

pipe valve (where fitted) and the auxiliary connection

valves.

- The pump must be protected from freezing whenever this

risk exists, and must be emptied in prolonged periods of

non-operation.

If, whilst the pump is in standstill, it must remain on standby

for service, start up at regular intervals for around 5 minutes

(see also 7.2.1)

- Fire pumps: 1x/month, at minimum.

- Drink-safe water pumps: 1x/48 hours, at minimum.

Note

- Reserve pumps: 1x/week, at minimum.

(It is best to change the operating pump every day).

The seal tightness and function of the auxiliary connections

must be examined during these start-ups.

6.2 Service limits

6.2.1 Switching frequency

In order to prevent abnormally high temperatures and

overloading of the motor, pump, coupling, seals, etc, the

switching frequencies must not be exceed the following

number of start-ups per hour:

MOTOR POWER MAX. SWITCHING/HOUR

Up to 3 kW 20

From 4 to 11 kW 15

From 11 to 45 kW 10

From 45 kW 5

6.2.2 Temperature of the liquid to be pumped

The permitted operation temperature is indicated in

the order and in the ATEX conformity declaration. If

the pump is to work at a higher temperature or you do not

have the data sheet, please ask KSB ITUR.

6.2.3 Density of the liquid to be pumped

The power absorbed by the pump increases in direct

proportion to the density of the impelled liquid. In order

to prevent overloading in the motor, pump and coupling, this

density must not exceed that shown in the order and in the

ATEX declaration of conformity.

Loading...

Loading...