RWCP, RWCN

5

3 Transport and storage

3.1 Transport and handling

The transport and handling of the equipment must be

carried out using suitable means in line with the

weight to be supported. The weight is generally

shown on the delivery note or on the data plate. If it is not, and

the equipment cannot be handled safely, please contact KSB

ITUR.

Remember that the equipment should never be lifted using the

ring bolts of each of the elements, e.g. the motor and pump

ring bolts, which are exclusively for independent transport.

It is also important not to use the pump and

pipe flanges or joining elements, e.g.

couplings.

Discharge nozzle DN

[mm]

DN impeller [mm]

Impeller type:

- A (semi-open)

- C (channel)

- V (vortex)…

Series

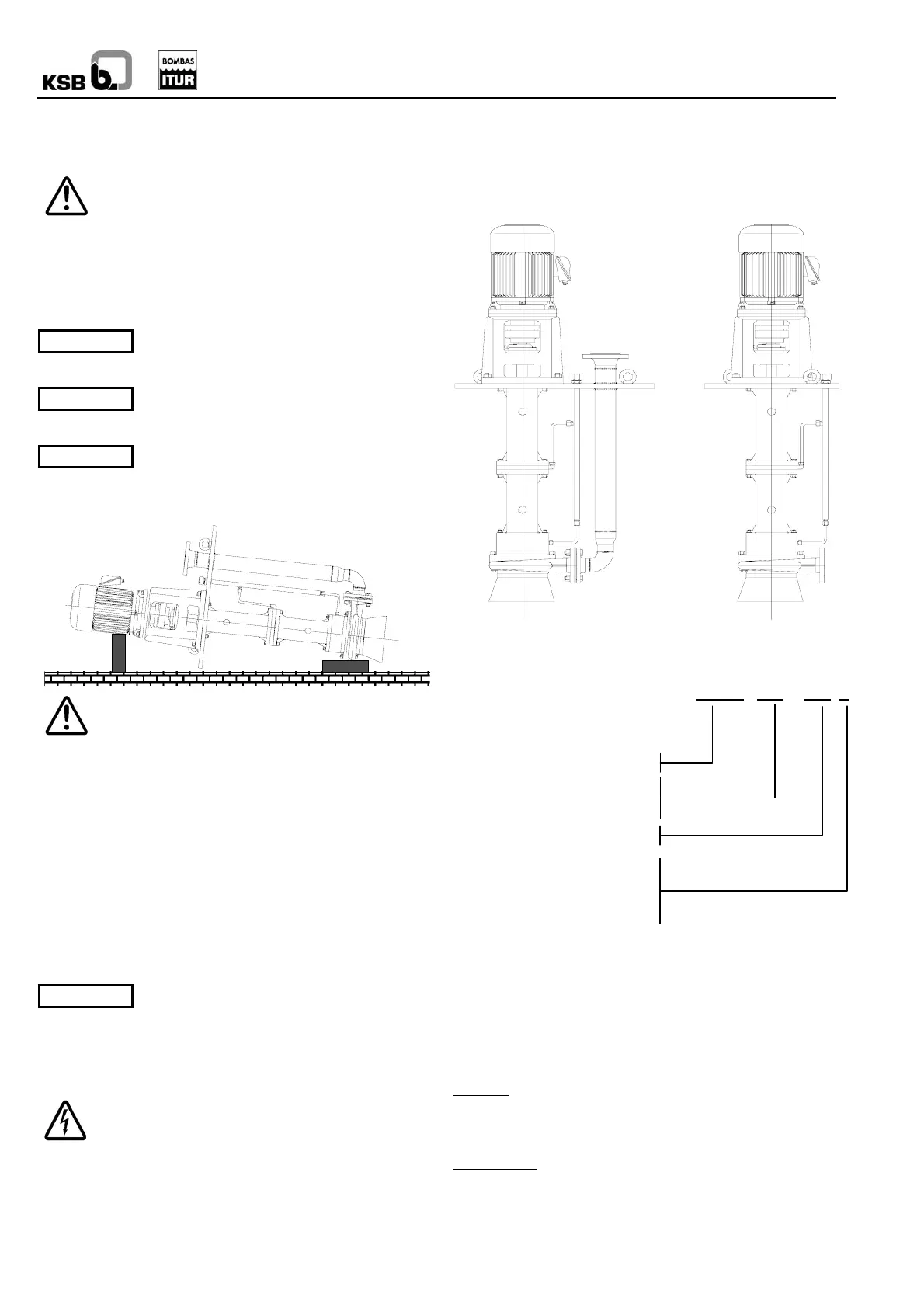

If the equipment is to be lifted using straps,

these must always be run underneath the

motor and pump support.

Do not position the pump on the filter/suction

hood. When positioning the pump outside of

the well on the ground, place a wood plug at the height of the

casing in order to prevent the suction hood from being a

support point for the pump.

When the pumps are dismounted from their transport

pallet, suitable means must be used to ensure the

stability of the equipment, until it is finally secured at

its definitive location.

3.2 Provisional storage/conservation

During provisional storage, it is only necessary to protect with

preservation products those low alloy parts in contact with the

liquid (e.g. grey cast, nodular cast, etc). Preservation products

available on the sector market can be used, in line with the

manufacturer's instructions on application and disposal.

The pump, or motor pump, shall be deposited in a dry site

where the relative humidity is as constant as possible.

When stored outside, it is necessary to keep the pump/motor

pump in an impermeable box, ensuring it does not come into

contact with external humidity.

Protect the stored product from humidity, dirt,

parasites and unauthorised access! All

openings must remain closed, and must not be opened until

necessary during assembly!

The shiny (mechanised) parts and surfaces of the pump must

be protected from corrosion using silicone-free oil or grease.

The electric motor must be disconnected, the

connection cables removed and the terminal box

closed with its cover on. The switchboards must be

in vertical position and disconnected.

4 Group description

4.1 General description

Vertical centrifugal pump designed for wells, ditches and

tanks. For neutral or aggressive liquids with significant solid

content.

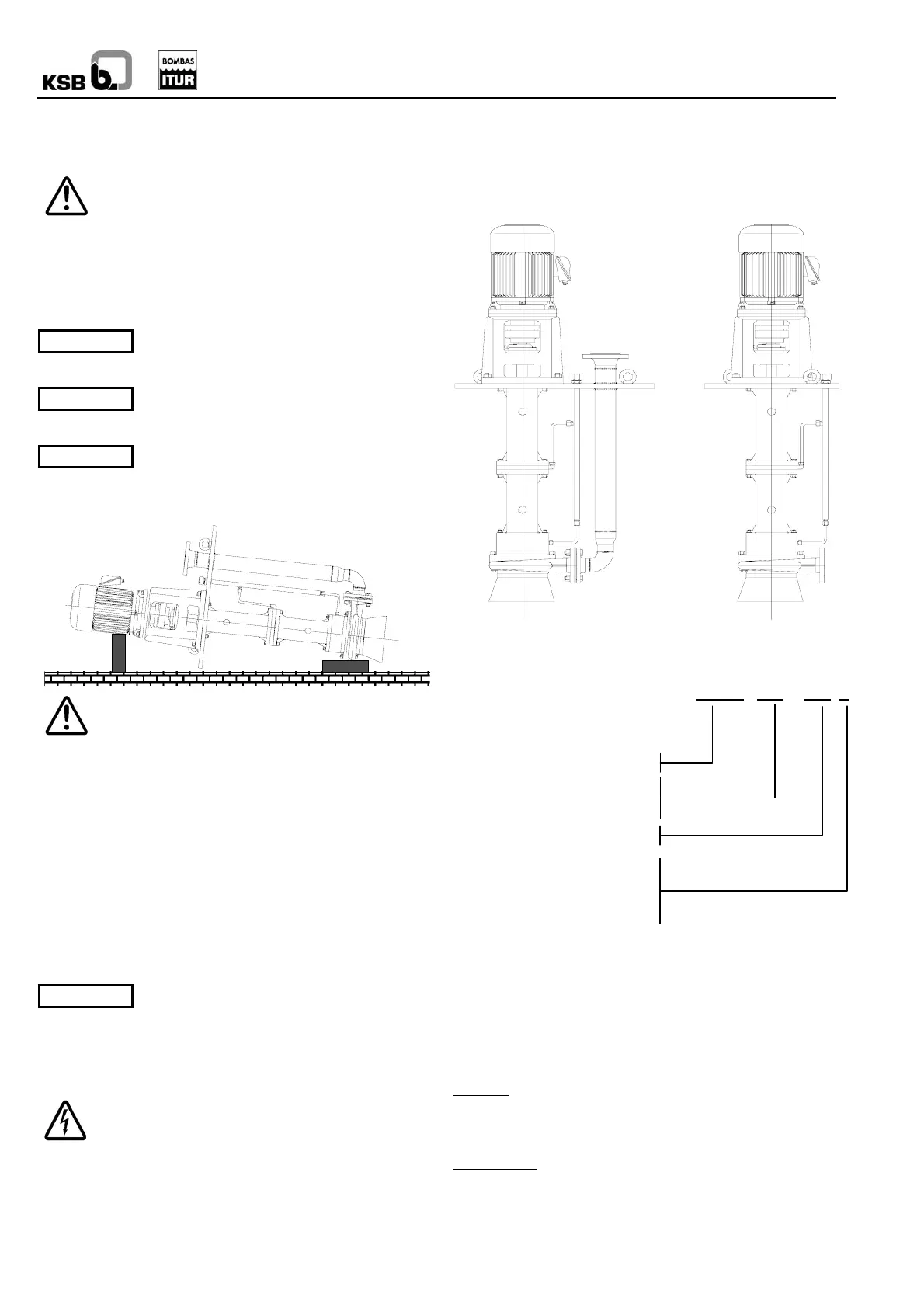

RWC

RWCN

Note

Note

Note

4.2 Denomination

RWCP

- 100 / 250 V

4.3 Form of construction

Volute pump casing with axial suction and radial impulsion.

Single-stage impeller semi-open, channel or vortex. Suction

hood.

Note

The RWCP series has a discharge pipe to the outside of the

base plate.

The RWCN series does not have a discharge pipe.

Bearings

: Both series are fitted with two classes of bearing:

grease-lubricated ballbearings or friction bearings lubricated

by the pumped liquid (when possible) or through the exterior

injection of liquid or grease.

Shaft sealing

: The standard sealing system is by way of a

retainer. This can be done optionally using a packing or

mechanical seal.

Loading...

Loading...