RWCP, RWCN

8

pump suction, always aiming to achieve the most stable

flow possible.

- If several pumps are working in parallel in a single well,

they should be at a suitable distance from each other, or

precautions should be taken to ensure there is no

disturbance which may affect the suction conditions of

the pump.

The maximum liquid level must always be below the

base plate in order for it not to overflow.

Dry well. Suction conditions

In this type of installation we need to:

- In the pump suction, avoid sharp angle joints and

accessories which lead to brusque narrowing and

widening.

- Position a gate valve in the suction to isolate the pump

during maintenance.

- With a pipe, take the excess fluid of the column from the

orifice in the upper column through to an upper level at

the maximum water level of the suction tank or suitable

drainage system.

The minimum liquid level in the well in start-up must be a least

0.5 m above the pump suction flange, and must be maintained

at sufficient height as to avoid air coming in through suction

due to the vortex effect.

5.3.1 Auxiliary connections

The equipment is normally delivered mounted and ready for

immediate operation, with only the hydraulic and exterior

electrical connections being necessary.

In the case of dirty or abrasive pumping liquids in which it is

necessary to connect the auxiliary refrigeration connections or

lubrication of the equipment, follow the instructions detailed in

7.2.2 or in annexes to this manual.

Auxiliary pipes are designed exclusively to

support internal strains due to the pressure of

the circulating fluid, to which end it is forbidden to subject

them to additional exterior strains (e.g. leaning on them, etc).

If the pumping liquid is fuel and the leak can lead to

ignition, this contingency should be avoided through

constant control of the seal tightness of the auxiliary pipe

joints by the plant operator.

5.4 Electrical connection:

The electrical connection must be carried out by a

specialist electrician! Applicable regulations must be

complied with.

Check the mains voltage available with the factory plate data

and choose the appropriate connection.

The technical connection conditions and the conditions

of the local energy supply company must be observed

when carrying out the connections.

We strongly recommend the use of a safety circuit

breaker for the motor and a thermistor associated to a

trigger device.

These instructions apply to asynchronous three-phase

standard electric motors with a squirrel cage both in

horizontal and vertical execution, in IP-23, IP-54 and IP-55

protection grades, with frame sizes of between 56L and

355S, both inclusive, with voltages of 200 to 500 V

between phases

The electric motor as well as whole electric installation

shall accomplish with all safety norms that may be

applied to it.

Earthing

Before starting up the pump, the earth of the pump, the

baseplate or the motor must be connected to an effective

earthed point of the installation.

5.4.1 Motor connection

Whilst connecting the cables, ensure it is not possible

for voltage to appear.

Check that the earth connection is in line with local

regulations.

The coupling may produce a source of ignition or high

temperature in the event of incorrect operation. For

this reason, the motor must be classified with at least the

same type of zone and temperature as the pump. It is

necessary to follow the instructions in the coupling manual

which is included with the pump.

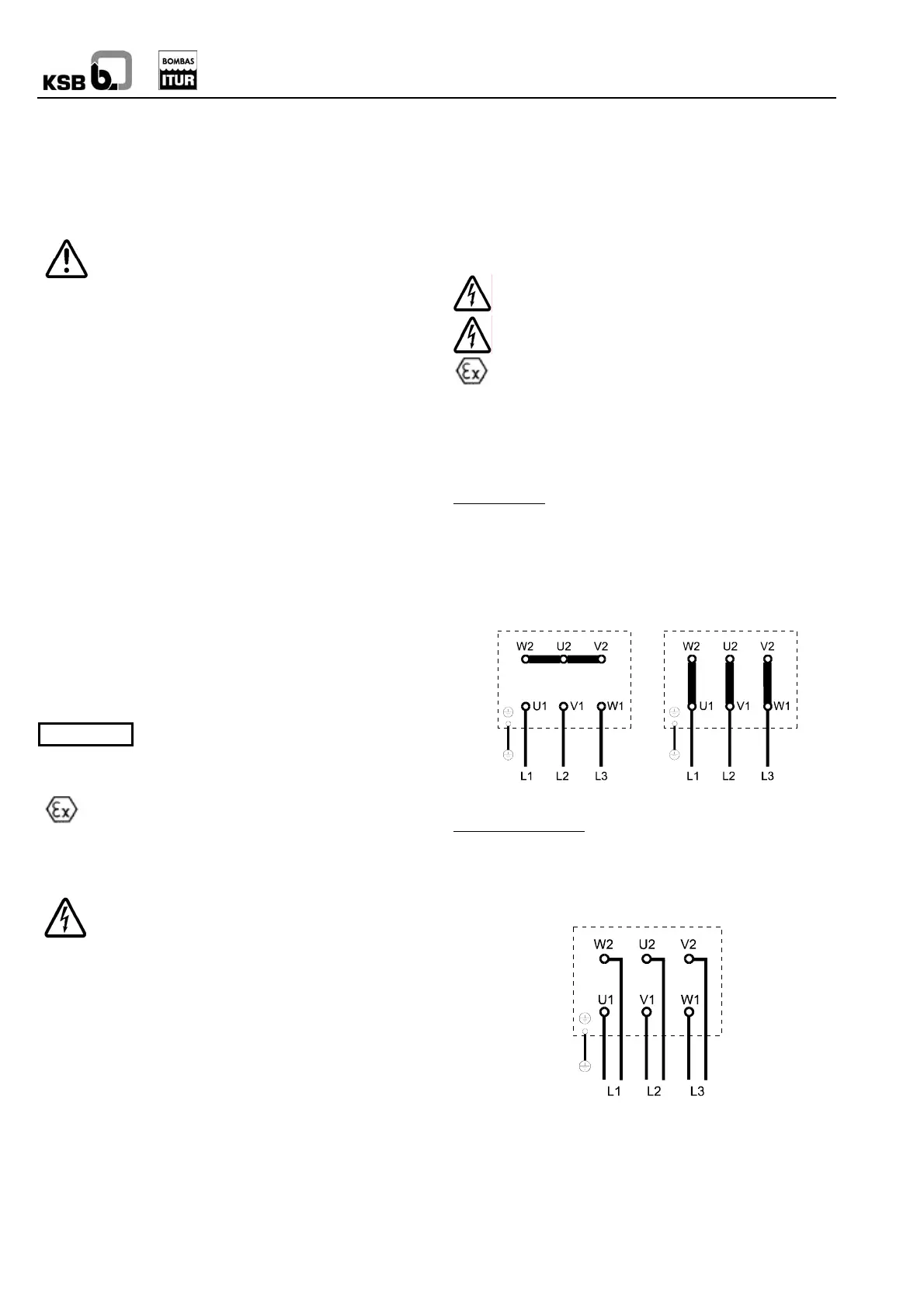

Connection in single speed motors

Direct start-up:

In direct start-up the motor can be used in two different

connections:

The voltage and the connection, e.g. 400 VY, 240 VD is

stamped on the motor plate. This means that the motor can

connect at 400 volts in star connection (Y) or at 240 volts in

triangle connection (D).

Note

Star connection Triangle connection

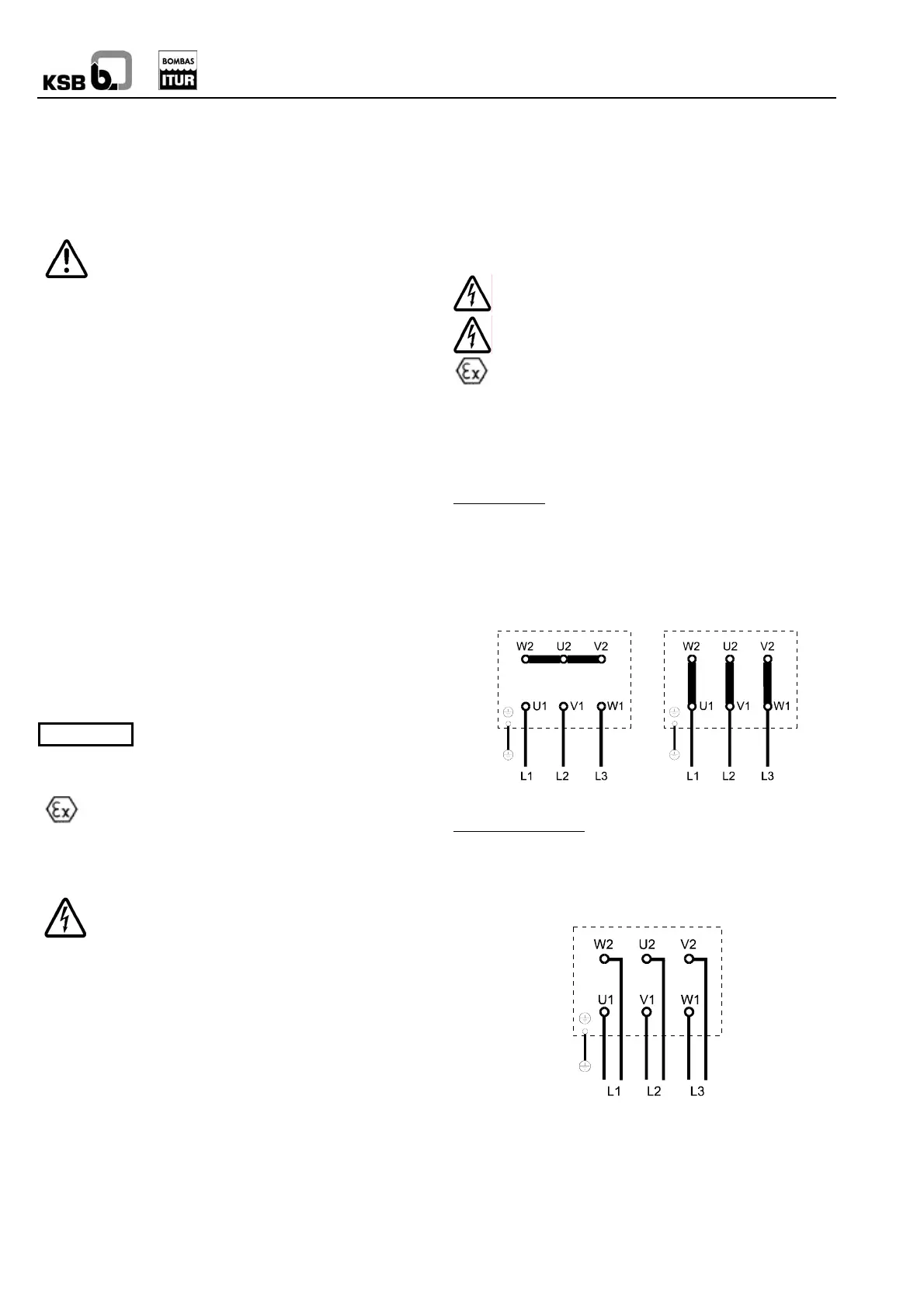

Star-triangle start-up:

In star-triangle start-up, the line voltage must coincide with the

voltage shown on the motor for triangle start up (D). The six

terminals indicated in the following diagram will be connected:

Connection to the star-triangle contactor

Loading...

Loading...