RWCP, RWCN

14

7.5.2 Mechanical seal (when fitted)

Mount in reverse order to dismounting.

For the correct operation of the seal it is

necessary to at least:

- Take great care when cleaning the different parts of the

mechanical seal, especially the contact faces. Not use

lubricant; use only clean water with a cloth for cleaning

optical devices.

- Not damage the O-rings during assembly.

7.5.3 Packing (where fitted)

- Introduce the packing gland and the cover along the

shaft.

- Mount and secure the cover on the lantern support.

- Cut the new packing, forming as many rings as required.

The cuts, seen from above, may be straight or inclined at

45º.

- We recommend leaving a small clearance of 0.5 mm in

the packing cut.

- Position the rings one by one, pushing on them but

without excessive force. The rings shall be introduced

with the cut ends alternated 90°.

- Take care to introduce the lantern ring in the same order

as before.

- Once the packing has been introduced, check that the

shaft rotates freely without any stiff points.

- Secure the packing gland. The packing gland must not

penetrate the entire free length. If necessary, introduce

more rings.

- Gently tighten the packing gland nuts.

- In order to determine the appropriate torque of the

packing proceed as indicated in point 7.2.1

7.5.4 Pump

Proceed in reverse order to that described above, taking

special care:

- When mounting the shaft in the support, take care to

ensure it does not tilt and maintains the axial direction

with the support.

- To introduce the different elements, use a plastic

hammer, banging gently in order to prevent damage to

the ball bearings, seals and bearings.

- Proceed to lubricate the bearings.

- Do not forget to position new joints. There should be no

clearances and the joints should be perfect.

The pump materials have been selected in

accordance with the process fluid indicated in the

datasheets. If this fluid is modified, check with KSB ITUR that

the new fluid is suitable for the pump.

- Note that the mounted intermediate bearing support is

not symmetrical, since it presents a larger interior

diameter on one side than on the other. Tighten the keep

pin which secures the intermediate bearing. The smaller

interior diameter part of the intermediate bearing support

must remain towards the bottom, on the side of the

pump.

- Use your hand to check that the shaft rotates freely every

time a piece is mounted.

- If the friction bearing has been removed from its position

in the cover, clean the inside of the cover and the

exterior bearing surface before returning it, and use a

plastic hammer to hit an intermediate piece into place.

Do not forget to position the keep pin which fixes the

bearing to the pump cover.

Note

- It is very important to check that the bearings are

perfectly aligned with the shaft, without any gaps which

may lead to the deviation of the shaft.

- The impulsion pipes of the RWCP series pumps must

take a position perpendicular to the support plate without

presenting tensions or deviations from the shaft.

- Check the correct positioning of pieces,

especially seals, bushing and impellers.

Note

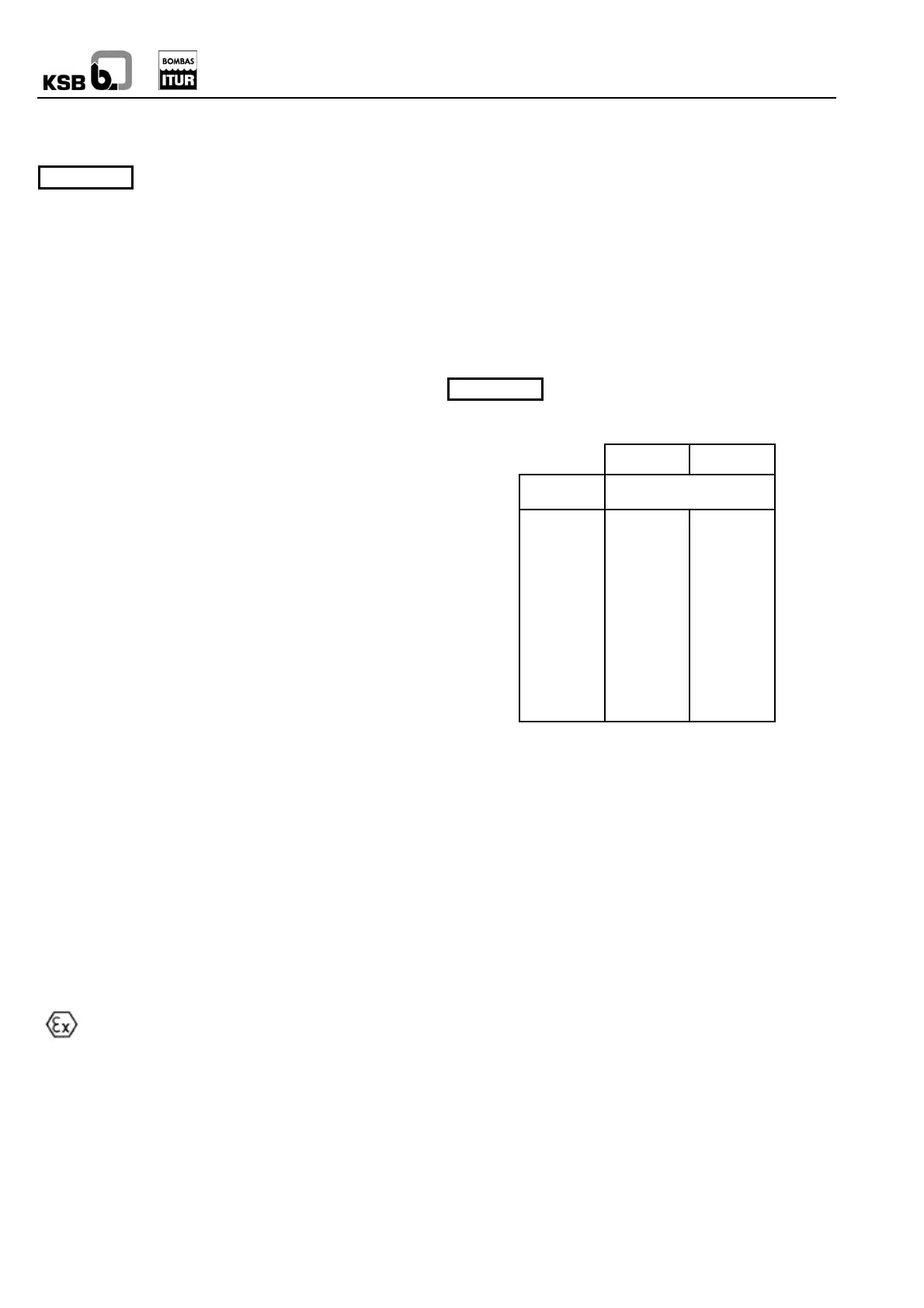

7.5.5 Tightening torque of the screws/nuts

Steel

Stainless

steel

ISO Metric

thread

Tightening Torque in [N·m]

(for non-lubricated thread)

M4 3.1 2.15

M5 6.1 4.25

M6 10.4 7.3

M8 25.2 17.7

M10 49.5 34.8

M12 85.2 59.9

M16 211 148

M20 412 290

M24 710 276

M27 1050 409

M30 1420 554

Loading...

Loading...