26

There is a 101.6 mm dust outlet located on the lower left of the saw cabinet allowing for the

connection to a dust collection system (not included).

Air current speed is 20m/s for vacuum suction dust emission index. When air current speed of dust collector device (in accordance with EN

12779:2004+ A1:2009) is not lower than 20m/s, ensure machine can be normal exhausted. User must wear dustproof mask.

1. Fit the 4" dust hose over the dust port, (not included) and secure in place with a hose clamp.

2. Make sure the hose could not come off.

3. Required air flow: 934 m

3

/h

4. Ensure pressure drop of each dust collector outlet carrying air current speed: 1500Pa

5. Wind speed of dust collector tube m/s: dry chips: 20m/s, water content is equal to18% wet chips: 28m/s.

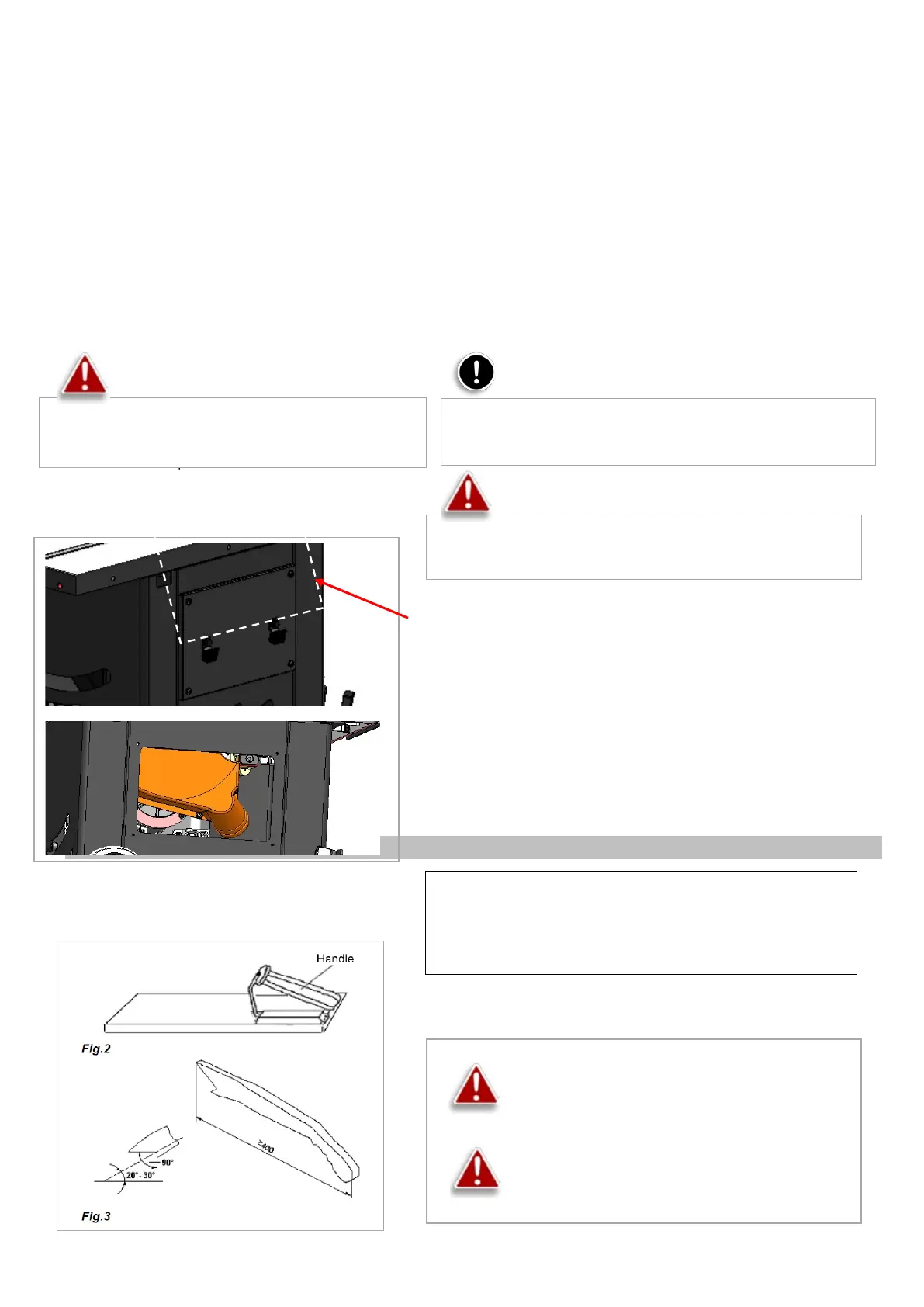

To clean wood chips

Remove the side cover, to clean and remove dust, debris from dust Hood

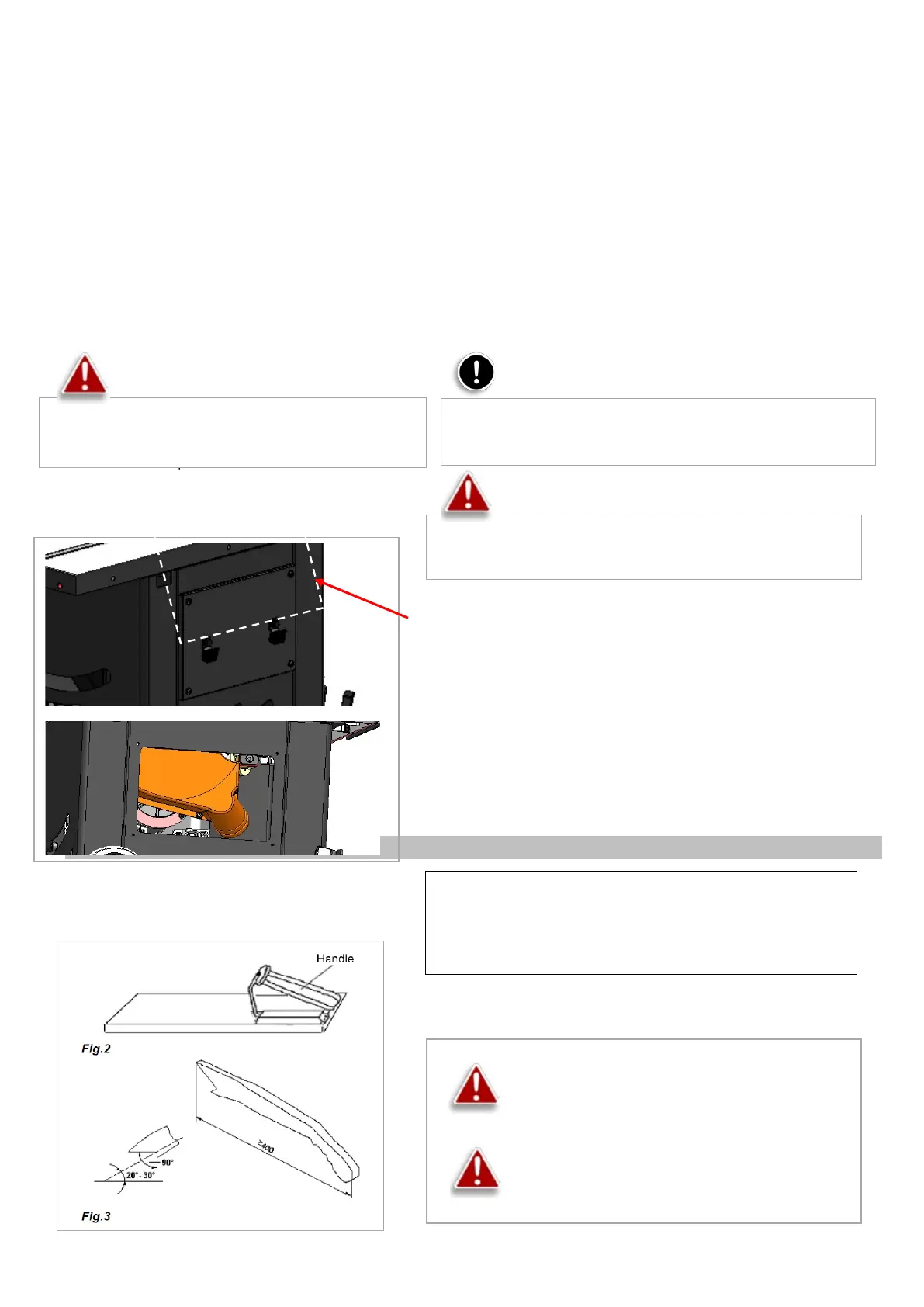

PUSH Block and Push stick

A push block (Fig.2) and A push stick (Fig.3) must be used

Warning:

Always turn on the dust collector

before starting the saw and stop the saw before

turning off the dust collector.

Note:

A tight fit is necessary for proper performance.

Warning:

Always turn off the table saw before removing

any cover of the machine

Warning:

Use only the push stick provided by the

manufacturer or constructed in accordance with the

instructions. This push stick provides sufficient distance of

the hand from the saw blade.

Warning:

Never use a damaged or cut push stick. A

damaged push stick may break causing your hand to slip

into the saw blade.

If the workpiece is less then 120mm, you must use the push stick to

prevent your hands from getting too close to the saw blade.

push block must be used to cut narrow workpieces and, when necessary,

to push the workpiece against the fence, a push block can be easily made

by the operator as Fig.2,

Loading...

Loading...