LAUNCH Electronic Two-post User’

14

5.

..

.Solutions to FAQ

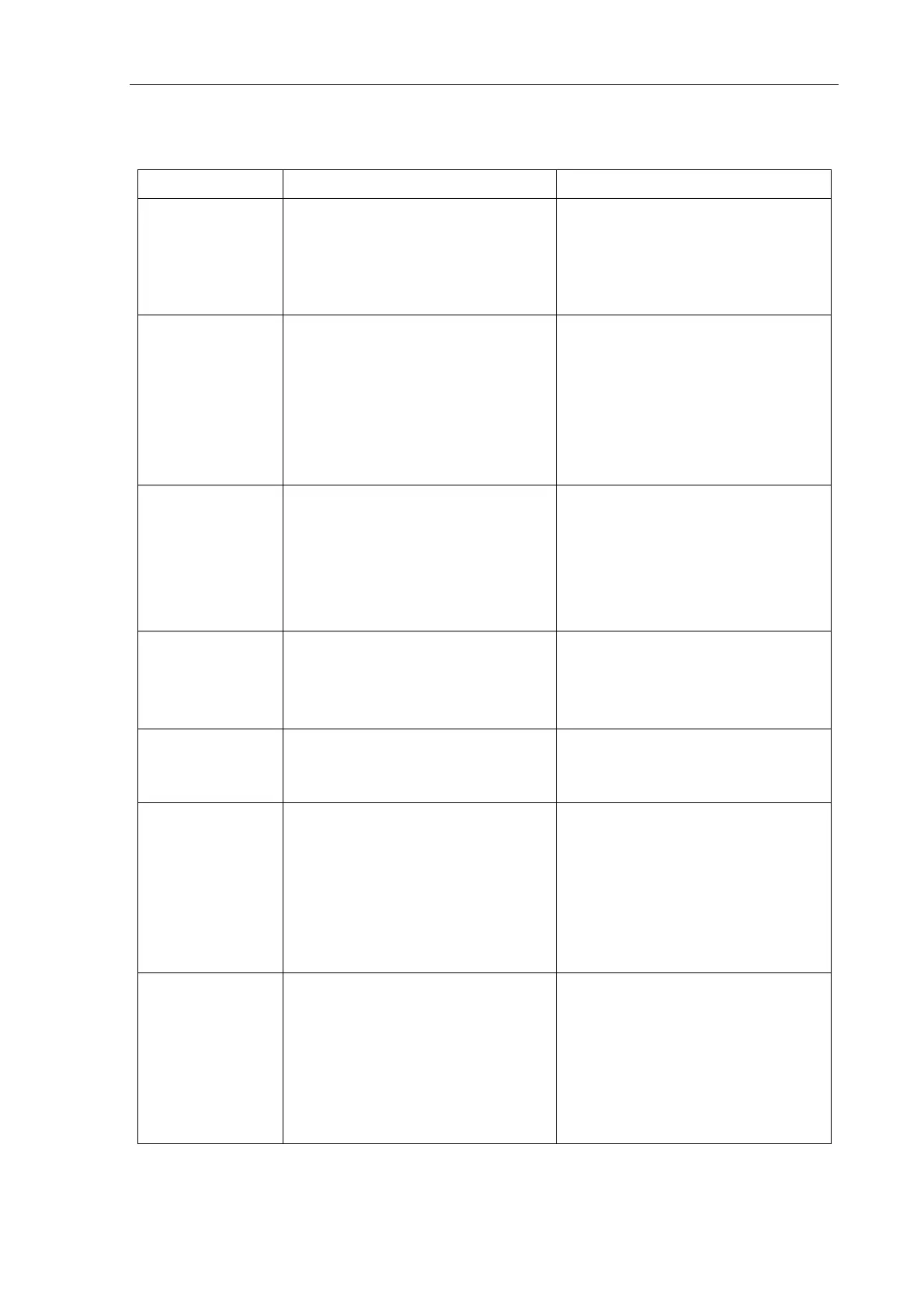

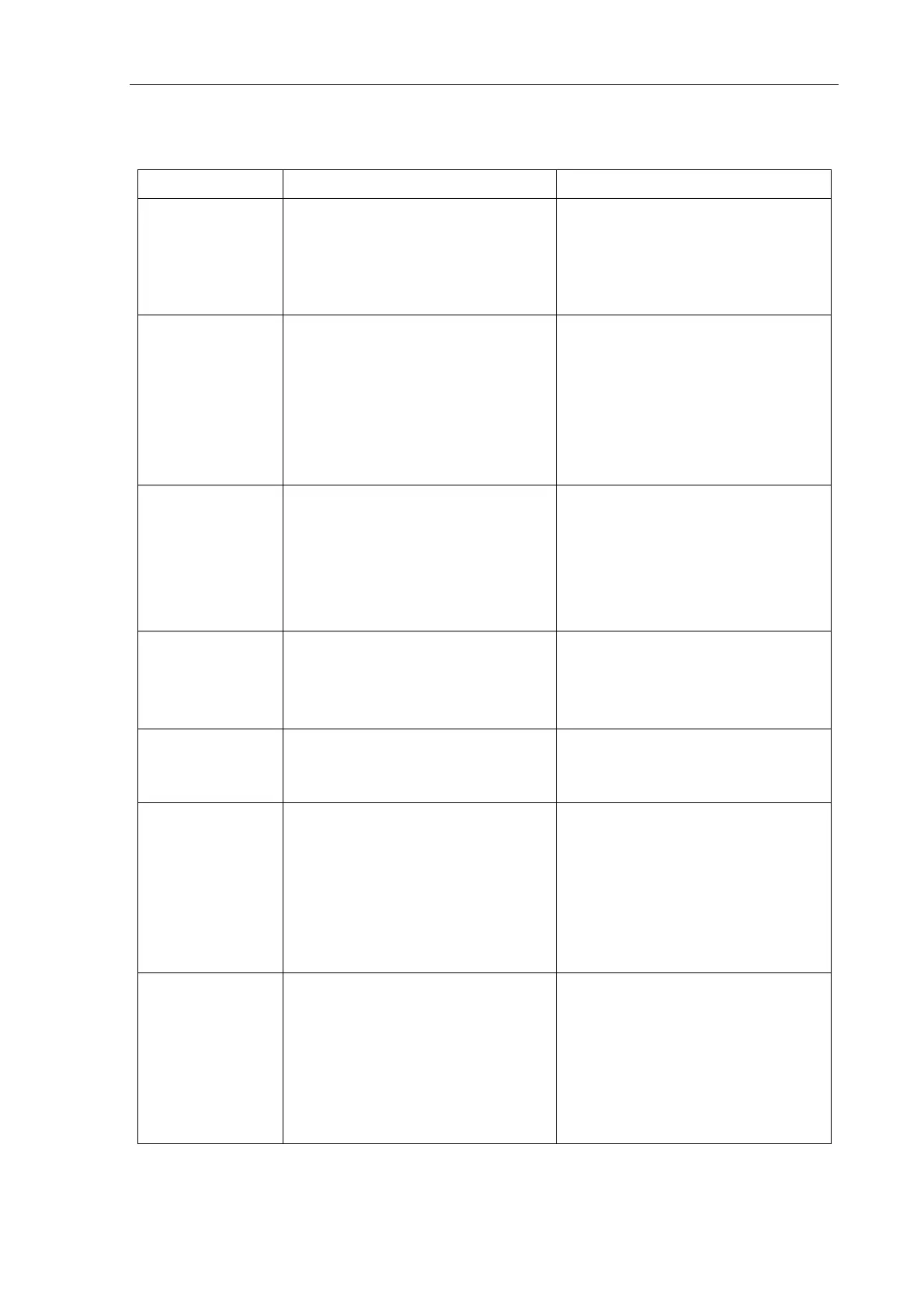

Symptom Reason Solution

Motor not operation

Check the circuit breaker or fuse

Check the voltage to the motor

Limit switch is failed

♦ Motor wire is burnt

Replace the burnt fuse or reset the

circuit breaker

Supply correct voltage for motor

Replace the limit switch

♦ Replace the motor

Motor is running, but

the lift can’t be raised.

Motor rotation reversed

Solenoid valve body open.

Hydraulic pump sucks the air

Suction tube is separate from the

hydraulic pump

Low oil level

Change the motor rotating direction by

changing wire connection.

Repair or replace the solenoid valve

body

Fasten all the suction pipe fittings

Replace the suction tube

Add the oil into the oil tank

Motor is running, the

lift can be raised

without load, but the

vehicle can’t be raised

Motor is running under low voltage

Impurities inside the solenoid valve

body

Regulation pressure of safety valve is

incorrect

Lift is overloaded

Supply correct voltage to the motor

Remove impurities from the solenoid

valve body.

Adjust the safety valve

Check the weight of the vehicle

The lift is lowering

slowly without

pressing the down

button

Impurities on the solenoid valve body.

External oil leakage

Clean the solenoid valve body

Repair the external leakage

The lifting speed is

slow or oil flows out of

the oil fill cap

Air and oil are mixed

Air and oil suction are mixed

Oil return pipe is loosened

Replace the hydraulic oil

Fasten all the suction pipe fittings

Re-install the oil return pipe

The lift can’t rise

horizontally

Balance cable is not adjusted properly

The lift is installed on the slop floor

Adjust the balance cable to the proper

tension

Shimming the columns to level the

lift(no more than 5mm), If exceeding

5mm, pour new concrete floor and

make it leveled. Refer to installation

description.

Anchor Bolt is not

fastened

Hole is drilled too big

Concrete floor thickness or fastening

force is insufficient

Pour the fast curing concrete into the

big hole and reinstall the anchor Bolt ,

or use new drill to drill the hole for

re-positioning the lift

Cut open the old concrete and make

new concrete slab for the lift. Refer to

installation description.

(C) Diagtools; www.diagtools.eu; diagtools@diagtools.lv; Pernavas 43A, Riga, Latvia, LV-1009; +37129416069

Loading...

Loading...