LAUNCH Electronic Two-post User’

15

6. Repair and Maintenance

Keep clean

This unit should be cleaned with dry cloth frequently

to keep it clean. Before cleaning, first switch off the

power to ensure the safety.

The working environment of this unit should be clean.

In case of dust in the working environment, it will

speed up the parts wearing and shorten the service

life of the lift.

Every day:

Before the operation, carefully check the safety

mechanism of the lift to ensure the electromagnet

suction and release action is proper, and the safety

plate is in good condition. When finding any abnormal

situation, make adjustment, repair or replacement

immediately.

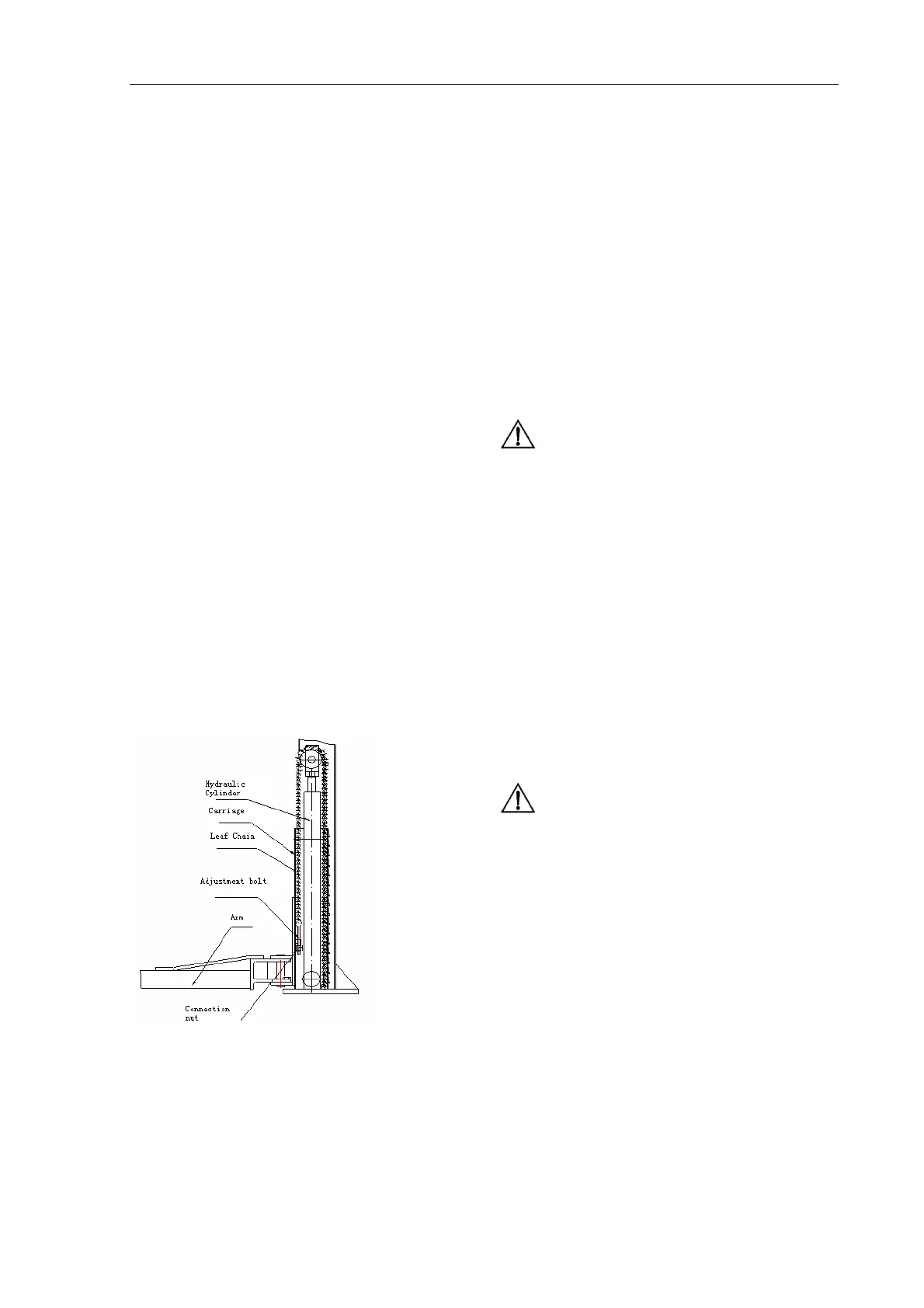

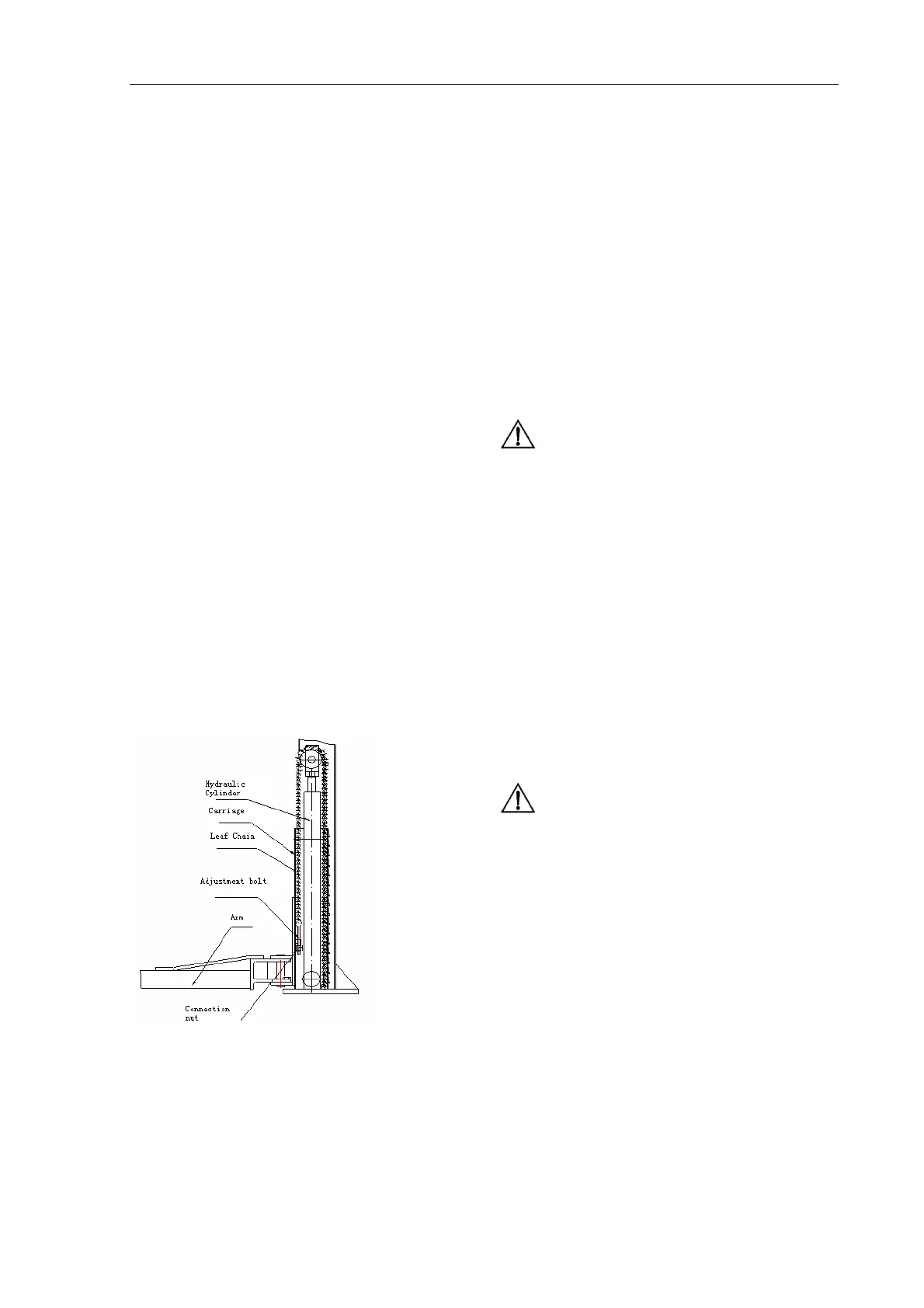

Check to see if the connection between hydraulic

cylinder and carriage is proper, if the connecting nut

between the steel chain and carriage is loose or

falling. Refer to Fig.4

Check to see if the steel cable connection is proper,

and if the tension is at the optimum status.

Fig 4

Every month:

Retighten the anchor Bolt s.

Lubricate chains/cables.

Check all the chain connectors, Bolt s and pins to

ensure correct installation

Check all the hydraulic lines for wearing

Check to see if the carriage and the inner side of the

column are properly lubricated. Use high-quality

heavy lubrication grease (lithium based lubrication

grease GB7324-87).

Note: All the anchor Bolt s should be tightened

completely. If any screw doesn’t function for some

reason, the lift can not be used until the bolt is

replaced

Every six months:

Check all the movable parts for possible wearing,

interference or damage.

Check the lubrication of all the pulleys. If the pulley

has dragging during the lifting and lowering, add

appropriate lubricant to the wheel axle.

When necessary, check and adjust the balancing

tension to ensure the horizontal lifting and lowering.

Check the verticality of the column.

Note: The inner corner of each column should be lubricated

with lubricant, to minimize the roller friction and ensure the smooth

and even lifting.

Maintenance of hydraulic system:

Clean and oil change

In the six months after initial use of this unit, clean the

hydraulic oil tank and replace the oil, later clean the

hydraulic system once a year, and replace the oil.

See Fig. 5.

Replace the seal

After this unit is put into operation for certain period, if

finding the oil leakage, carefully check it; if the

leakage is due to the wearing of sealing materials,

immediately replace the worn one based on the

original spec. See Fig. 5

(C) Diagtools; www.diagtools.eu; diagtools@diagtools.lv; Pernavas 43A, Riga, Latvia, LV-1009; +37129416069

Loading...

Loading...