________________________________________________________________________________________________

_______________________________________________________________________________________________

Operation Manual Page 20 of 27

Pipe beveling process

Danger of being injured by flying chips

• Never work without the saw blade guard

mounted

• Wear protective goggles.

Important Notice: If the machine is out of operation for

long time

• Turn the cutter motor by 180°

• Switch on the machine and let the cutter motor

run for about 10 seconds

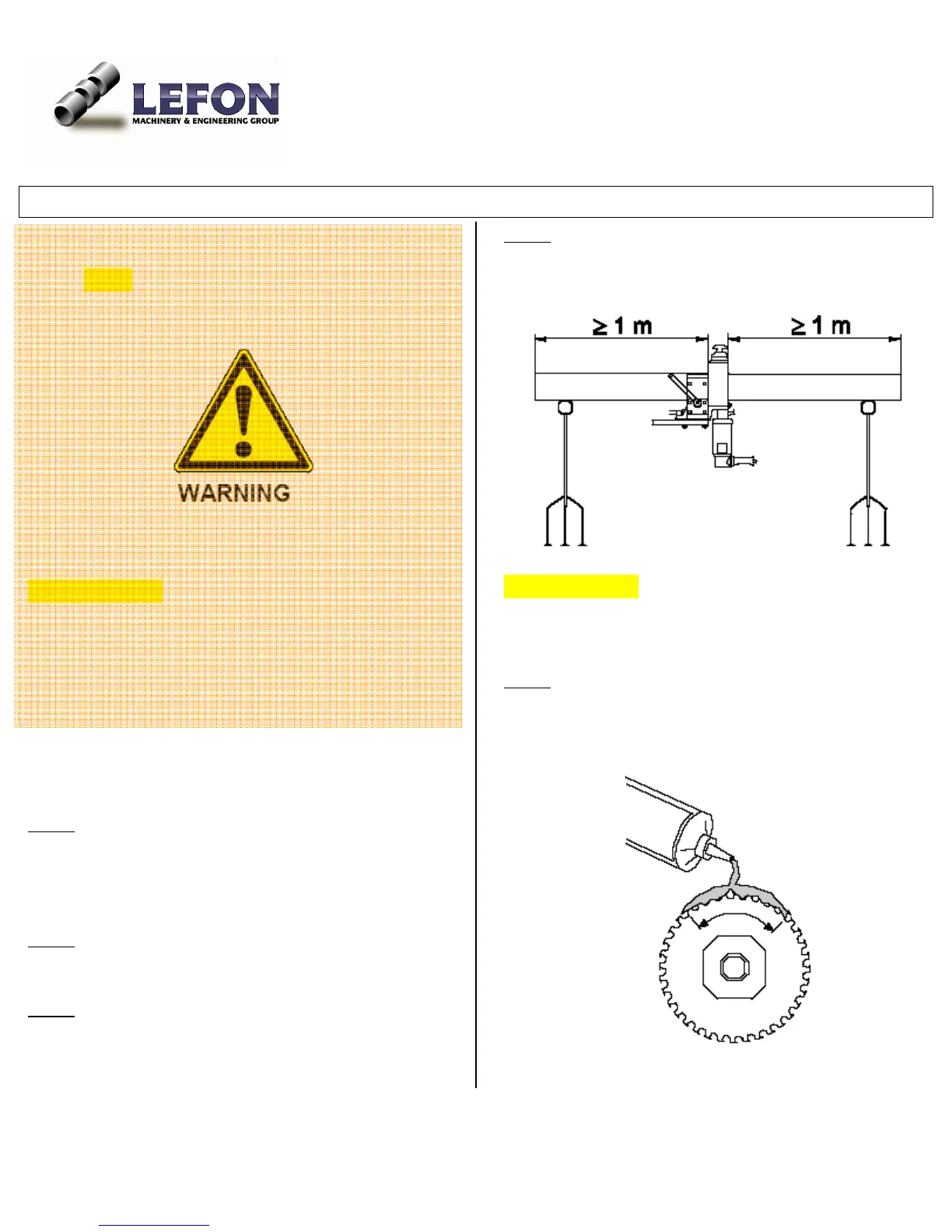

Procedure to bevel the pipe

Step 1: Make adjustment to top handle wheel

Compatible for the pipe diameter. (Refer to earlier

description )

Step 2

: Adjust the cut-off stop if used.

Step 3: Set the spindle speed

Step 4

: Push the pipe through the vice up to the desired

length and clamp it. Support pipes at each end if the

open end is longer than 1meter.

Important Notice: Take the clamp handle off before

rotating the slide housing.

Step 5: Apply blade lubricant to the saw blade.

• Lubricant / every 3 cuts, < 2” wall thickness

• Lubricant / every 1 cut, > 2” wall thickness,

or with chrome, high quality steel pipes.

Loading...

Loading...