7 MAINTENANCE

• Correct machine servicing is necessary with a view to

reliable and safe working.

• Maintanance should always be carried out whilst the

PTO shaft between the tractor and the machine is

disconnected.

7.1

Maintenance after operations

• Clean the machine thoroughly. After jet-cleaning allow for

a few moments rotation of the discs so that the water is

swept away.

• Check the mower knives and discs for tightness and

damage (see par. 7.3).

• Check the safety cover for damage.

• Grease the machine with a rust preventive.

• Grease the piston rod with an anti-corrosion agent if a

longer period of inactivity is anticipated. Remove the agent

when putting the machine back into operation. If not,

sealing of the ram may be affected after hardening of the

anti-corrosion agent.

7.2

Lubrication

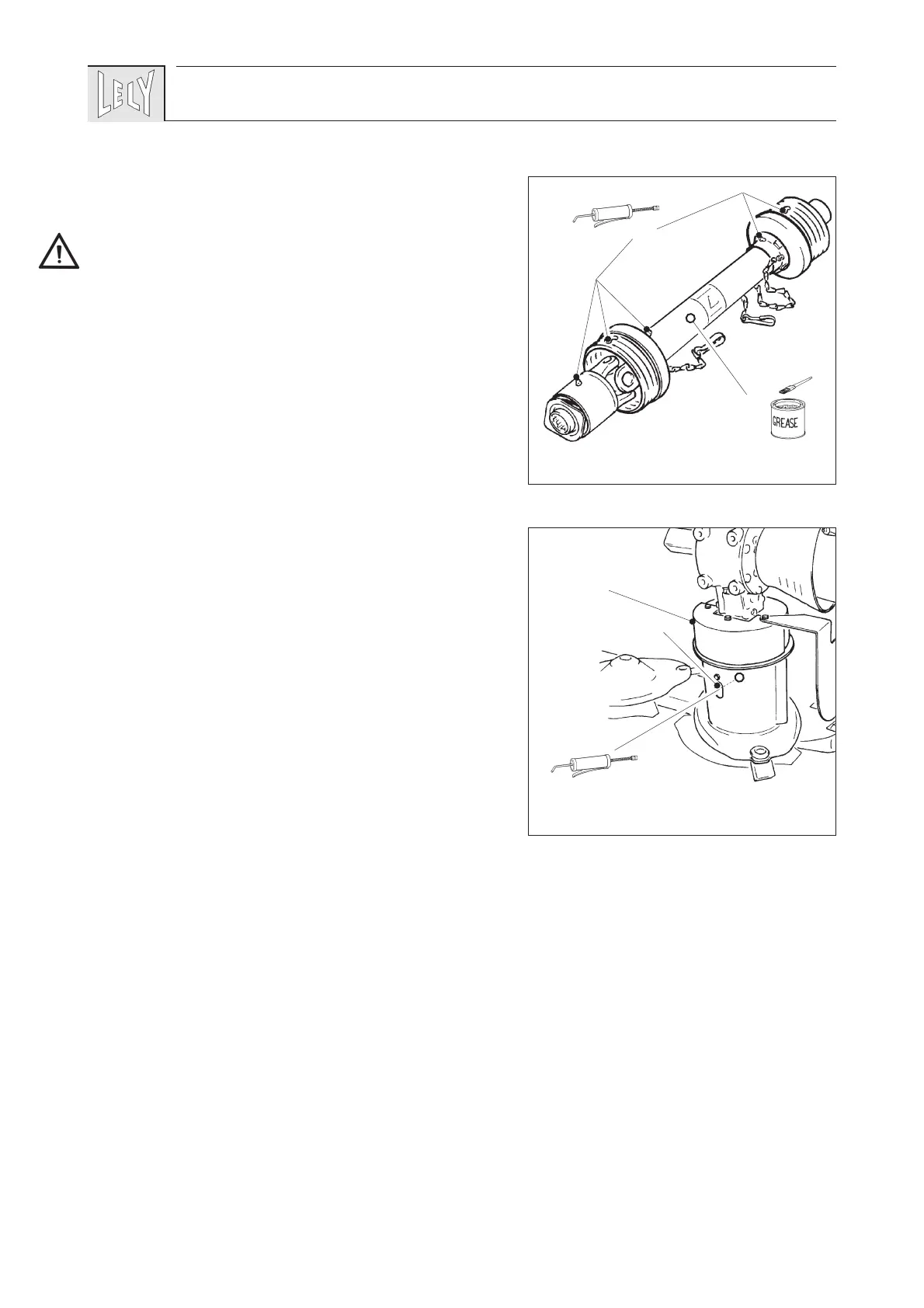

• PTO shaft to be greased every 8 working hours by the

grease nipples on the cross assemblies, protection tubes

and free wheel clutch (fig. 15).

• Profiled tubes of the PTO shaft to be greased every 8

working hours.

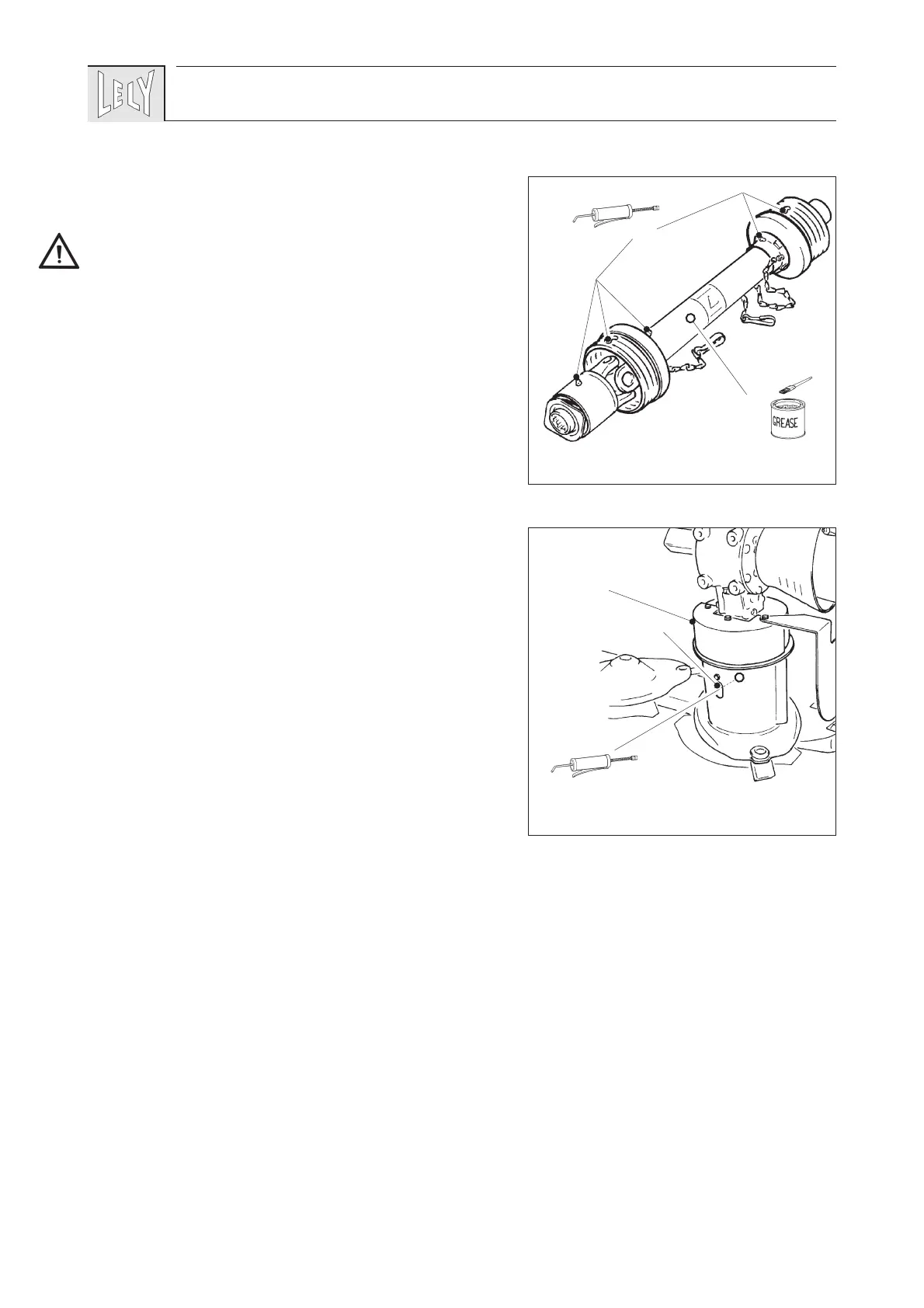

• Grease the PTO shaft above the drive element every 100

working hours in way of the grease nipples on the cross

assemblies. For this purpose, the cover A (fig. 16) and the

sealing plate B have to be dismounted. Remove soil and/or

crop material, if any, from the hat.

• Grease the pivots of the intermediate frame every 40

working hours.

• Grease the bearing blocks of the conditioner rotor every 8

working hours (fig. 17).

• Grease or lubricate all remaining pivot points every 40

working hours.

• Apply a few drops of oil to the cams of the breakback

device every 40 working hours (fig. 18).

39

15

16

A

B

8h

8h

100 h

Loading...

Loading...