Commissioning

5-5

L MA9300PLC EN 1.4

5. Select a feedback system

• Drives with resolver (default setting)

– No changes required

• Drives with other feedback systems

– Select feedback system under C0025

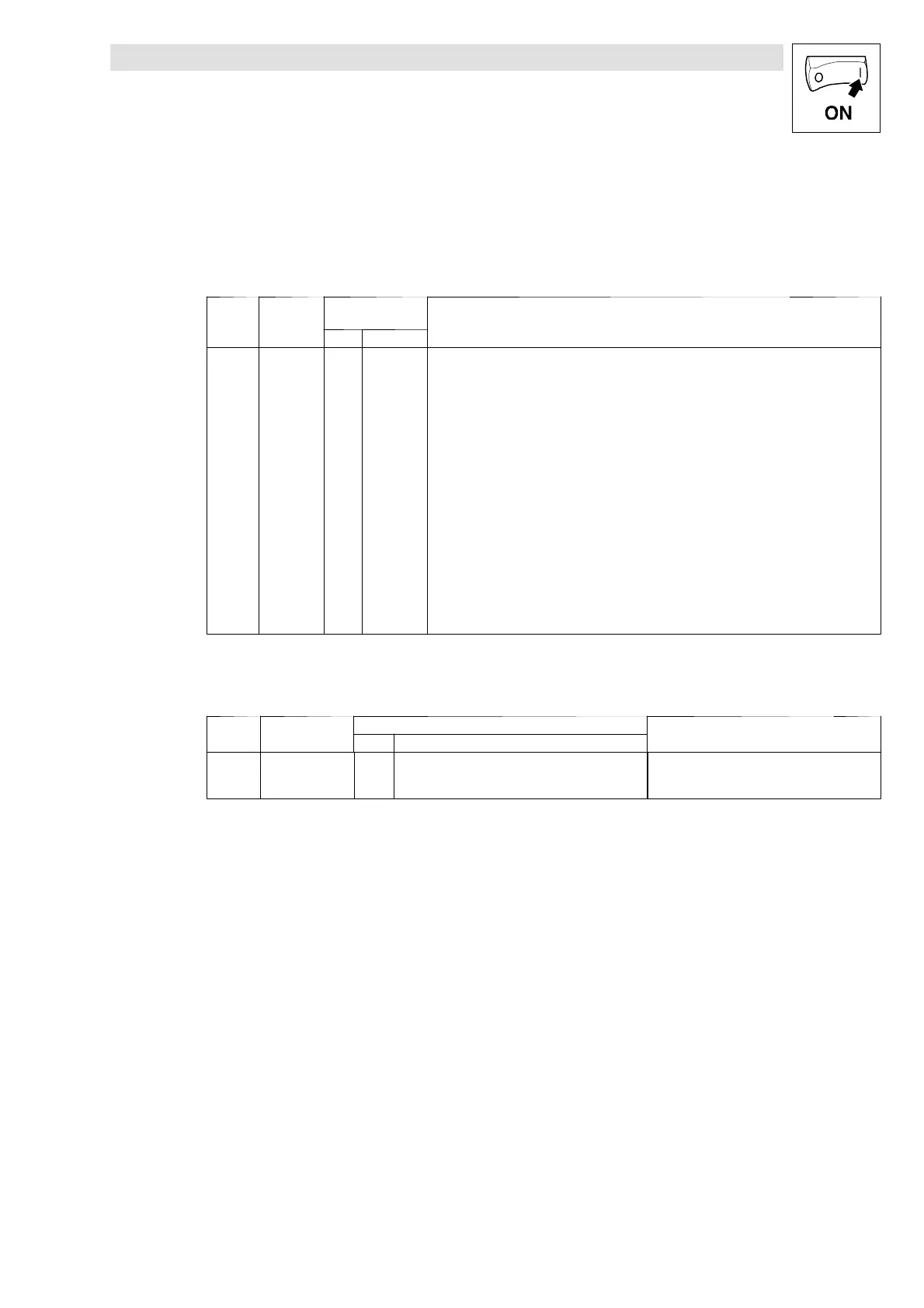

Code LCD

Possible

settings

Important

Lenze Selection

[C0025] Feedback

type

10 0

10

Selection of the feedback system

• Input of the encoder specified on the nameplate of the Lenze motor:

110 ... 113

210 ... 213

310

– C0025 automatically changes C0420, C0490, C0495

à 0 COMMON: C0420, C0490 or C0495 was changed subsequently

410

es

e

:

e

es

e

s

es

gna

e

w

.

à 110 IT-512-5V

111 IT-1024-5V

112 IT-2048-5V

113 IT-4096-5V

Inc

emental enc

de

with

le

el

à 210 IS-512-5V

211 I

-1024-5

-

-

212 IS-2048-5V

213 IS-4096-5V

Sin-cos encoder

à 310 AS-512-8V

-

u

-

u

à 410 AM-512-8V

Single-turn: Sin/cos encoder with RS485 interface (Stegmann)

– Set encoder voltage under C0421:

(Menu: ”Motor / Feedb.”, submenu: ”Feedback” or

menu: ”Motor/Feedback system”, submenu: ”Feedback systems”)

Code LCD

Possible settings

Important

Lenze Selection

[C0421] Encoder volt 5.00 5.00 {0.1V} 8.00 Set supply voltage for the encoder used

CAUTION:

incorrect input may destroy the encoder

6. Set the maximum speed under C0011.

7. Use C0105 (QSP T

if

) to set the deceleration time required for quick stop.

8. Controller is ready for operation:

– Green LED blinking:

Controller is ready for operation, continue with step 9.

– Green LED off and red LED blinking:

Interference occurred. Before proceeding with the commissioning, eliminate the fault (see

Chapter 6 ”Troubleshooting and fault elimination”).

9. Enter C0003. Set C0003 = 1 to store all data entered.

10.Enable controller

– Green LED is on if a HIGH signal (+13V ....+30V) is applied to X5/28 HIGH-Signal and no

other source of controller inhibit is active.

11.Speed preselection according to the program for first commissioning “DryRun”

(^ 5-3)

Loading...

Loading...